Clean hydrogen production technologies such as water electrolysis have attracted attention to dealing with climate change and environmental pollution.

Water electrolysis is considered a promising technology that can generate hydrogen without carbon dioxide (CO2) emissions.

However, the challenges of lowering energy efficiency due to high operating voltages remain.

The Need for Hydrogen to Fight Climate Change

According to recent data from the Global Carbon Project, global CO2 emissions from fossil fuels are expected to reach 37.4 billion tonnes in 2024, reflecting a 0.8% increase compared to the previous year.

This trend violates the global efforts to work towards a carbon-neutral society, underscoring the urgent need to reduce fossil fuel consumption and develop alternative clean energy technologies.

Despite global efforts to reduce the use of fossil fuels, CO2 emissions continue to rise. As demand for clean energy grows, hydrogen that does not release CO2 during combustion is emerging as a promising energy resource.

Hydrogen has a high energy density, which is significantly higher than traditional solid fuel energy density. Additionally, hydrogen plays a key role in addressing the challenges of intermittent renewable energy supply, such as solar and wind power sources.

By converting excess power into hydrogen and storing it, hydrogen provides a viable solution for energy storage and transportation. To fully realize this possibility, it is important to generate hydrogen in a carbon-generating manner.

Benefits of chemical water electrolysis

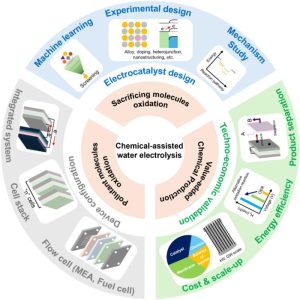

Chemical water electrolysis has emerged as a promising solution to address these challenges.

This technique produces hydrogen at low voltage by replacing hydroxylation reactions (OERs) with various chemical oxidation reactions such as ammonia, alcohols, urea, and hydrazine.

Additionally, it offers the potential to simultaneously enhance energy production and promote environmental improvements by generating high value products and eliminating pollutants.

In this study, a team of researchers introduced various chemical water electrolysis systems and systematically analyzed the latest catalyst design strategies to address the high overpotential problems of each reaction.

“Chemical water-assisted electrolysis technology represents an innovative approach to overcome the limitations of traditional water electrolysis, allowing for clean hydrogen production with improved energy efficiency,” explained Ho Win, professor at Seoul National University.

“This study systematically compiled modern catalyst design strategies and demonstrates the potential to improve the energy efficiency of various chemical water-assisted electrolytic reactions.”

Can you overcome technical challenges?

However, there are still many technical challenges in chemical water electrolysis, which replaces traditional electrolysis methods.

Important issues include maintaining catalyst durability and achieving low voltage operation. This has been addressed actively through electrochemical reaction mechanism research and AI-driven catalyst design.

Industrial applications require high current density (CM-2) and long-term stability (over 10,000 hours). Recently, researchers have been working on membrane electrode assembly (MEA), a direct assembly of the anode, membrane and cathode, to reduce electrical resistance and mass transfer losses while achieving high current density.

Additionally, fuel cell-type devices have been developed that operate under high temperature conditions for high performance, and efforts are being made to develop self-mounted hydrogen production systems.

The future of electrolysis-based green hydrogen production

As these developments progress, electrolysis of chemical waters can become a critical technology in the transition to sustainable clean energy solutions.

“The main goal of this review is to quickly and accurately provide readers with the latest research trends and catalyst design strategies in this field, and to outline a comprehensive blueprint for industrial applications,” concluded Chan.

Source link