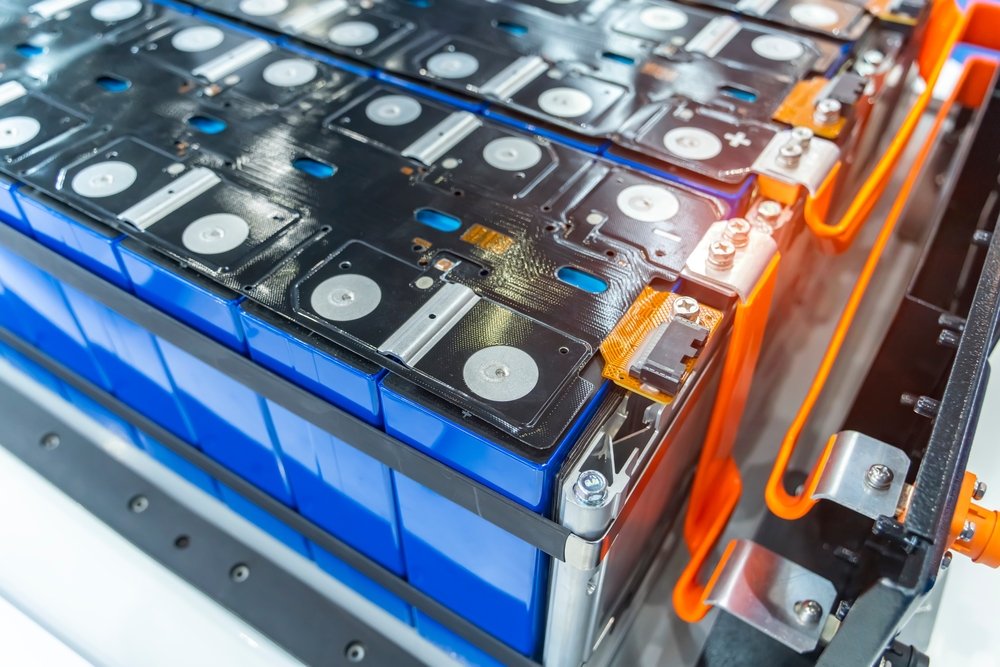

As electric vehicles (EVs) become more mainstream, lithium-ion batteries remain under the spotlight, not only for performance but also for safety.

The hidden challenge known as lithium plating threatens both. Although EVs offer a greener alternative to traditional cars, microscopic accumulation of lithium metal during charging can quietly extend battery life and, in extreme cases, pose serious safety risks.

Currently, researchers at Shanghai University for Science and Technology have unveiled cutting-edge solutions that could change the game.

Using artificial intelligence and standard electrical measurements, lithium-plated detection systems can identify problems early with accuracy above 97%, paving the way for safer and longer-term EVs without costly hardware upgrades.

Lithium plating explained

Lithium plating is a failure mode that occurs inside lithium-ion batteries while charging. Typically, lithium ions flow into the graphite anode of a battery and are stored between layers in a process called intercalation.

However, under certain conditions such as rapid charging, low temperatures, and high charging conditions, these ions are not properly inserted. Instead, they accumulate on the surface of the anode as metallic lithium.

This unwanted lithium accumulation forms a layer that can reduce battery capacity and efficiency. More dangerously, it can grow into needle-like structures known as dendrites.

These dendrites can puncture holes in the internal separator of the battery, causing a short circuit, which can lead to overheating, fires, and even explosions.

Lithium plating develops and evolves rapidly at the microscope level, so detecting it before it becomes dangerous has been an important challenge up until now.

Machine learning meets battery safety

The Shanghai-based research team has developed a smart lithium plating detection and warning system that relies on random forest machine learning algorithms.

Unlike traditional detection methods that often require expensive or invasive tools, this system works by analyzing electrical data collected during pulse charging. This is a way to temporarily charge and rest the battery to generate a measurable response.

The algorithm uses this data to identify subtle but consistent electrical patterns that indicate that lithium plating is formed. Impressively, the system achieved detection accuracy of over 97.2% using only standard voltage and current signals already available in most battery management systems (BMS).

No physical changes to the battery are required. Easily integrate technology into a wide range of platforms.

From simple data to complex insights

What makes this solution particularly innovative is the use of multidimensional feature extraction. In single variable analysis, multiple functions such as internal resistance changes and voltage relaxation behavior were only 68.5% accurate, resulting in a dramatic increase in detection rate.

This approach reveals lithium-plated fingerprints hidden in the battery’s normal operating data. These early metrics help predict and prevent failures before escalation, providing engineers and systems with real-time insights into battery health and safety.

The system runs on existing hardware and relies on common electrical measurements, allowing it to be deployed as a software update for current BMS units or integrated into cloud-based management tools.

This means that EV manufacturers and energy storage companies can quickly adopt the technology without having to redesign their battery systems.

Researchers also consider the possibility of expanding the model to other types of lithium-ion batteries used in devices such as smartphones, drones and grid-scale energy storage.

Future versions may even adjust charge rates based on the real-time risk of lithium plating and adapt to fast charging environments.

A safer road for electric vehicles

It is essential that EVs continue to address battery reliability and safety on behalf of combustion engine vehicles around the world.

This AI-powered lithium-plating detection system provides manufacturers with powerful tools to extend battery life, increase safety and build trust in electric mobility.

This breakthrough highlights how data-driven technology can solve even the most complex engineering problems, bringing you one step closer to a smarter, cleaner, safer energy future.

Source link