BioFibreLoop: Bio-inspired, laser-based functionalisation on bio-based materials leads to recyclable functional garments.

The EU textile industry is at a crucial turning point in terms of sustainable production and rapid adaptation to consumer demand for smart functions. The production of functional textiles often uses chemicals that cannot be recycled, which poses new challenges for the EU textile industry due to increasing regulations and strict bans on hazardous chemicals. Therefore, smart innovations are needed to help the textile industry eliminate the use of harmful chemicals and reduce its carbon footprint. BioFibreLoop will develop such innovations.

The paper presents the first results of the projects. It covers the specification, selection, development and production of textiles, the lignin-based coating, the development of appropriate digital tools, the safety and sustainability framework and finally some considerations on the industrial demonstration later in the project, before concluding with some information about the project.

Innovative textiles

The BioFibreLoop project is developing functional textiles made from renewable and recyclable raw materials (lignin, cellulose, and polylactide (PLA)). To protect these textiles from liquids, gases, UV light, and bacteria, a thin lignin coating is applied to the textile surface. The project is also developing a novel, highly environmentally friendly surface treatment to give the lignin coating increased water and oil repellence beyond its natural material properties.

In the first year of the project, the German Institutes for Textile and Fibre Research successfully spun fibres from lignin blended with a suitable cellulose that increases suppleness and strength, in three development stages. A particular challenge was the limited availability of suitable base lignin types from suppliers in wood refineries in Europe. Small companies founded a few years ago with special high-quality lignin types no longer exist, and larger ones often do not produce the required grades.

However, with new wood refinery plants currently being built or commissioned in Europe, we are very confident that a good supply of base lignin of correspondingly high quality will be available in the near future. Spinning continuous fibres in the melt-spinning process places high demands on homogeneous compounding and the rheological behaviour of the melt. If everything is perfect, multifilament with common textile counts can be spun and drawn. The slightly brownish, fine, and smooth continuous fibres exhibit a slightly shimmering sheen in the small sample fabrics produced (see Fig. 1). Further work on chemically modifying the lignin/cellulose blends is planned to increase fibre-related strength.

Further textiles made from other renewable raw materials are produced by European textile partners FreyZein, TecnoTex, and NIL Textile as woven, knitted, and nonwoven fabrics. These fibres consist of cellulose (mostly also derived from wood, regenerated cotton), and polylactic acid (PLA) from corn starch. Numerous textile samples were produced with variations in fibre composition, basis weight, and longitudinal and transverse stress-elongation behaviour. These samples were evaluated, and a portion of the selected variants was used to produce larger samples on industrial equipment for lignin coating development. After washing, these samples are cut into narrow strips for DITF’s smaller laboratory facilities.

To coat textiles, films are produced at the DITF from a mixture of lignin and cellulose (see Fig. 2). Here, too, the particular challenges initially lay in the extensive screening of European raw material suppliers and the evaluation of the biopolymers with regard to film-forming capacity, compound grain size, extensibility, and melting point. Three selected compounds with the required good properties are now available. With regard to recycling, we are focusing on a coating mixture that is the same or similar to that used for fibre production. When the coating and textiles use the same material, recycling is fundamentally much easier, as complex separation processes can be avoided. Thermal recycling with melting, cleaning, and reuse in fibre and coating production is, therefore, fundamentally possible.

These films are produced in a laboratory extruder with a slot die. In a subsequent step, these base films are modified with variable thicknesses and uniform properties on heated calanders. The coating onto the textiles takes place in a lamination process, in which the film and the textile are heated and thus thermally bonded. The particular challenge here lies in the development of the process technology, as the melting temperatures of the lignin films are the same or similar to those of the lignin fabrics (approx. 180°C) or can be even higher, for example, compared to PLA textiles (Fig. 3). Despite this challenge, laminations can also be achieved on PLA nonwovens with good adhesion, so that the open 3D structure of the nonwovens is retained.

with lignin

Furthermore, BioFibreLoop is demonstrating progress in the development of new technology for creating water- and oil-repellent surfaces. To this end, the participating researchers and staff members intensively analysed previously known surface structures of selected plants and fish. The micro- and nanostructures on the surface cause the aforementioned functional properties. From these findings, a physical theoretical model was derived to better understand the relationships between micro- and nanostructures and the properties of the liquids to be repelled. The major challenge now lies in transferring these structures to the surfaces of the lignin coating using a novel, laser-based embossing process.

The laboratories of ALPHANOV in France and the DITF are already conducting intensive research into metallic surfaces for transfer, special laser technologies, and the many variations of embossing techniques. Two different types of lasers are used to create the required topographical details on metal surfaces. These surfaces are transferred to the coated textiles in an embossing process under the influence of temperature and pressure. Contact angle measurements with water and diiodomethane show a tremendous increase in water and oil repellence through such structuring, (see Fig. 4).

Digital tools

In a landscape shaped by the urgent demands of decarbonisation and digital innovation, as outlined in the European Commission’s EU Strategy for Sustainable and Circular Textiles (2022), the textile sector is undergoing a profound transformation. In this context, the BioFibreLoop project emerges as a transformative initiative, fusing sustainable material innovation with advanced digital tools. Central to this ambition are Digitalisation Tools, delivering a powerful suite of digital solutions to accelerate the development of circular, bio-based textiles.

At the heart is the creation of a comprehensive digital twin (DT) of the BioFibreLoop production processes.² The project establishes a fully structured database of design and operational parameters, forming the foundation for the DT baseline.

A defining feature of the DT is its focus on metrics-based decision support. The DT and its AI enhancements will track key process indicators¹ – from functionalisation throughput to material recyclability rates — and benchmark them against sustainability and safety objectives aligned with the Safe and Sustainable by Design (SSbD) framework. This ensures the digital tools are not only operationally effective but also environmentally and socially responsible.³

To extend the impact beyond the consortium, we will deploy a Virtual Replication Tool (VRT) — an open, user-friendly digital platform for textile manufacturers across Europe. This VRT will democratise access to advanced modelling and simulation capabilities, supporting industrial players in adopting greener, digitalised production models. Through this tool, decision-makers can simulate production scenarios, test operational adjustments, and assess sustainability outcomes without physical trials — a game-changer for risk reduction and strategic planning.

Safety and sustainability assessment

As the textile industry faces increasing pressure to adopt more sustainable and health-conscious practices, the BioFibreLoop project seeks to lead by example. At the core of its mission is the integration of safety and sustainability across the development of three innovative, circular textile product lines. This ambition closely aligns with the European Chemicals Strategy for Sustainability⁵ and the JRC’s Safe and Sustainable by Design (SSbD) Framework⁴, both of which advocate for a more responsible use of materials and chemicals throughout the value chain.

This will play a central role in ensuring that BioFibreLoop innovations are not only technically viable but also safe for people and environmentally sound. Led by NFA, we take a life cycle approach, bringing together environmental, economic, health and social dimensions into a cohesive strategy for assessing the sustainability of each textile product line.

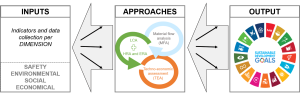

To support this, we are developing a dedicated safety and sustainability framework (Fig. 5). This framework will act as a structured roadmap, guiding the evaluation of impacts and performance from early design phases through to validation and demonstration. It will incorporate key design principles such as material efficiency, avoidance of hazardous substances, energy reduction, and recyclability and support the creation of detailed data libraries covering exposure levels, emissions, and other critical life cycle indicators.

As the products progress from concept to application, we will assess their performance across all relevant life cycle stages: manufacturing, use, recycling, and biodegradability. This evaluation will contribute directly to several UN Sustainable Development Goals (SDGs), including those linked to climate action, resource efficiency, and human wellbeing. The assessment will also account for potential trade-offs, such as the use of chemicals and energy.

The framework itself will be developed using both top-down and bottom-up processes. Drawing initially from international policy and methodological guidance (including the SDGs, the SSbD framework, and established life cycle methodologies), we will refine the structure through close collaboration with BioFibreLoop partners and stakeholders. This dual approach will ensure the framework is both scientifically grounded and tailored to the realities of the textile production chain.

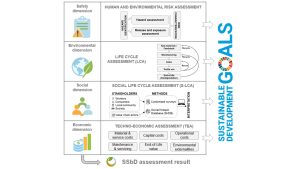

The final conceptual model (Fig. 6) will include four interconnected sustainability pillars: safety, environmental, social, and economic. Each pillar will be linked to specific tools and indicators, such as Human and Environmental Risk Assessment (HRA/ERA), Life Cycle and Social Life Cycle Assessment (LCA/S-LCA), and Techno-Economic Assessment (TEA).

By combining real-world data with internationally aligned methodology, we will enable both quantitative and qualitative assessments, supporting continuous learning and improvement. The resulting framework will not only guide sustainability evaluation within BioFibreLoop but also provide a replicable, policy-aligned roadmap for scaling safe and circular textile innovations across the industry.

Industrial demonstration

The project focuses on demonstrating biomimetic functionalisation technology in operational environments (Fig. 7), aiming to achieve a functionalisation yield of 10 m/min and 50 cm width (TRL 7). The specific objectives include biomimetic functionalisation of bio-based materials at the fabric level across three industrial sites in Germany (KNOPF), Austria (FreyZein), and the Czech Republic (NIL). We will evaluate the performance and durability of BioFibreLoop functionalities in garments for workwear, activewear, and outdoor products.

These tasks include:

Demonstration of lignin-based fabric functionalisation and garment manufacturing by Knopf, testing durability, resistance to stains, and integrating sensors for performance validation.

Demonstration of cellulose-based fabric functionalisation, with FreyZein testing hydrophobic and oleophobic properties, UV degradation, and wear resistance. IMEC will also integrate sensors for garment performance monitoring.

Demonstration of PLA-based fabric functionalisation by NIL, focusing on enhancing PLA fabrics’ resistance to hydrolysis and degradation during washing cycles. The garments will meet activewear industry standards.

Scalability and replicability planning for industrial deployment, including assessing technical feasibility, supply chain strategies, regulatory compliance, and developing a replication plan with potential business partners for technology scaling.

About the project

The consortium consists of 13 partners from nine different countries. It is composed of strong and innovative industrial partners in the active, outdoor and workwear industries, covering the whole textile value chain. They are complemented by academic partners who bring excellent expertise to the development of textile processes and technologies, as well as safety, sustainability, circularity, and recycling aspects.

In addition, the consortium includes actors in the social sciences who provide outstanding knowledge on stakeholder engagement and innovation management. The partners thus include a wide and complementary portfolio of competencies. This is a unique opportunity for cross-field fertilisation for experts with diverse expertise. The project is co-ordinated by DITF Denkendorf.

Disclaimer

BioFibreLoop is funded by the European Union Horizon Europe Research and Innovation Program under Grant Agreement No. 101130603. Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or the European Health and Digital Executive Agency (HADEA). Neither the European Union nor HADEA can be held responsible for them.

References

European Commission (2022). EU strategy for sustainable and circular textiles. Retrieved from https://environment.ec.europa.eu/strategy/textiles-strategy_en

Murzin, S. P. (2024). Digital Engineering in Photonics: Optimising Laser Processing. Photonics, 935.

Tran, K. P. (2021). Artificial Intelligence for Smart Manufacturing: Methods and Applications. Sensors, 5584.

Caldeira, C., Farcal, R., Garmendia Aguirre, I., Mancini, L., Tosches, D., Amelio, A., Rasmussen, K., Rauscher, H., Riego Sintes, J. and Sala, S. (2022) Safe and sustainable by design chemicals and materials – Framework for the definition of criteria and evaluation procedure for chemicals and materials, Publications Office of the European Union, Luxembourg, 2022, ISBN 978-92-76-53280-4, doi:10.2760/404991, JRC128591.

EC (2020). Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions – Chemicals Strategy for Sustainability Towards a Toxic-Free Environment, European Commission, Brussels, 14.10.2020. COM(2020) 667 final

Please note, this article will also appear in the 22nd edition of our quarterly publication.

Source link