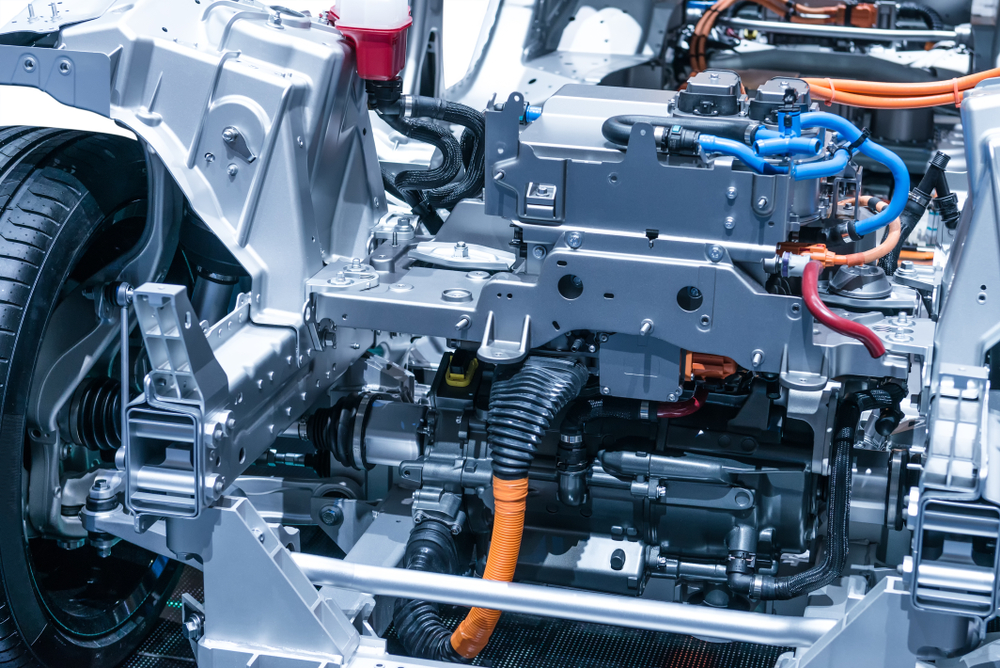

The evolution of electric vehicles (EVs) greatly depends on the progress of Power Train Technology.

However, developing these important components is a complicated, time -consuming and expensive process. Researchers at the GRAZ Institute of Technology (TU GRAZ) have introduced a revolutionary method that can dramatically shorten the timeline of electric vehicle powertrain development.

By utilizing artificial intelligence (AI) and advanced simulation models, optimization of electric drive (optimization of electric drive) can enhance the powertrain design of electric vehicles in one minute.

Optimization with AI: Future of EV development

The OPED system, which has been developed for nearly 10 years, integrates evolved optimization algorithms with component simulation models.

This innovative approach enables a completely automated powertrain optimization process, improving major elements such as power electronics, electric motors, and transmissions based on the specific requirements of the manufacturer.

By considering important factors such as cost, efficiency, and space restrictions, OPED guarantees the optimal design configuration that satisfies the demand of the industry.

In the conventional manual assist for optimization of electric vehicles, engineers need to test and improve their individual components so that they can break their bones.

In many cases, changing one element brings a cascade effect to other parts of the system, making the process very complicated.

With AI -drive type automation, OPED can quickly evaluate thousands of design variations and identify the optimal configuration in a few hours, not in a few months.

How OPED converts the development process

The optimization process starts with a manufacturer that inputs technical specifications such as power output, service life, speed requirements, and available space in vehicles.

With these parameters, OPED systematizes about 50 different design variables at the same time, and systematically eliminates the most optimal variants while improving promising configurations.

This continuous improvement process will eventually get the powertrain solution of an electric vehicle that is closely consistent with the priority of the manufacturer, whether focusing on energy efficiency, weight loss, and cost effectiveness. Masu.

The ability to rationalize this process provides competitiveness to automotive companies, and can focus on engineers from time -consuming manual calculations to high -level strategic decisions.

The efficiency of software has already attracted the attention of players in the main industries, and major Austrian automobile suppliers have been integrated into workflows.

From the month to 1 day: the power of AI

One of the most notable results of OPED is the ability to condenses the monthly development cycle to only one day.

By automating simulation, evaluation, and optimization, software deletes the need for thorough trial and error tests.

This acceleration not only reduces costs, but also promotes more agile development, so manufacturers have come to the market faster than ever.

AI -driven solutions like OPED are important in dealing with the increase in the complexity of electric vehicle technology.

The manufacturer is trying to meet the standards of more severe efficiency and sustainability, so the ability to optimize the powertrain component quickly and effectively is a game changer.

Sustainability and platform optimization

Beyond individual vehicle applications, OPED is designed to strengthen sustainable efforts.

Researchers have expanded software functions to evaluate and minimize the CO2 emissions in both the powertrain life cycle manufacturing stage and the operation stage.

This advanced approach guarantees that the impact on the environment is considered from the early stage of development.

In addition, the versatility of OPED extends to the optimization of the powertrain of the entire vehicle platform. By identifying shared components that can be used by multiple models, this software helps manufacturers reduce production costs and streamline supply chain logistics.

This innovation is particularly valuable for car manufacturers who try to standardize the powertrain elements of various EV models without impairing performance or efficiency.

A new era for powertrain development

The integration of the AI to optimize electric vehicles for optimization has shown a major advancement for the automotive industry.

The ability to automate and improve complex engineering decisions not only accelerates development, but also enhances EV powertrain efficiency, sustainability, and cost -effective.

As electric mobility continues to evolve, AI -led solutions like OPED play a very important role in forming high -performance and environmentally friendly vehicles of the next generation.

By shortening development time and improving design results, this technology has set new standards for innovation in the electric vehicle industry.

Source link