Superconducting Qubits, the basis of many quantum computing architectures, may have only taken on a major leap.

Researchers at Lawrence Berkeley National Laboratory have developed innovative manufacturing methods that significantly reduce noise, one of the biggest challenges facing quantum hardware today.

This breakthrough brings you closer to building scalable, high-performance quantum computers that can solve complex problems well beyond the scope of classical systems.

This advancement comes from Quantum Systems Accelerator (QSA), a multicenter initiative supported by the U.S. Department of Energy’s Advanced Scientific Computing Research (ASCR) program.

QSA focuses on engineering quantum technology that can solve complex scientific problems beyond the capabilities of classical computers.

QSA Director Bert De Jong emphasized the importance of breakthroughs. “Knowing how to create noise-bearing qubits will help us advance more efficient quantum computers to solve the scientific problems that are key to the Ministry of Energy’s mission.”

Why are superconducting Qubits important?

Superconducting qubits are one of the most promising Kikubit architectures due to their compatibility with current semiconductor manufacturing methods.

They rely on superconducting metals – materials that can direct power with zero resistance to storage and processing quantum information.

However, these qubits are notoriously vulnerable to environmental noise, especially due to surface defects and the unnecessary charge of the materials on which they are constructed.

This noise leads to calculation errors, one of the major hurdles in creating practical quantum systems.

Innovation: Lifting the Super Indoctor from Silicon

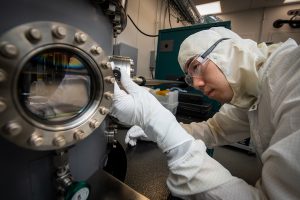

To address this, Berkeley’s lab-led team introduced a manufacturing method in which a critical circuit component, the Super Indoctor, was partially suspended on top of a silicon wafer.

Superderivatives that function similarly to traditional inductors by maintaining current flow are essential for conserving quantum states.

By etching certain parts of the silicon substrate under the Superinductor, the researchers reduced physical contact with the surface.

This lift design effectively protects qubits from interference, improving their reliability and performance.

The team achieved this using a gentle chemical etching and cleaning process carefully designed to avoid damage to vulnerable components.

This approach increases the inductance by 87% while maintaining the integrity of the superin derivative, and is a key improvement in stable quantum manipulation.

Modern chip making and scalable and compatible

One of the key benefits of this new approach is its scalability. The researchers implemented it on a 6-inch silicon wafer, making it suitable for integration with existing microchip manufacturing processes.

This opens the door for widespread adoption in the development of next-generation quantum processors.

This technique also supports accurate patterns, allowing hundreds of small superindoctors to be created on a single wafer, leaving the rest of the surface untouched. This level of control can help you build more complex and functional quantum circuits.

What’s next?

Going forward, the team plans to integrate this method into the manufacturing of full qubits for use in advanced quantum computing architectures, including 3D integrated systems.

By improving the noise resilience of superconducting Qubits, this breakthrough forms the foundation for a more reliable quantum computer that can solve real-world scientific challenges.

As quantum racing accelerates, such innovations will become key to unlocking the great potential of superconducting Qubits, bringing us closer to a future in which quantum computing will transform research and technology across the industry.

Source link