Fusion reactors are very promising as a future energy source, but can materials be designed to withstand the power of such artificial stars? A specialized facility built in a Dutch laboratory demonstrates how small labs create large splashes for fusion science.

“Where are you preparing for the next shot?” Scientists and engineers wait for the overhead status screen clock to count seconds. Then, a sudden flash of bright light from a computer monitor: onboard camera, quickly descending and resolves the dizzying glare into a beam of glowing hot gas.

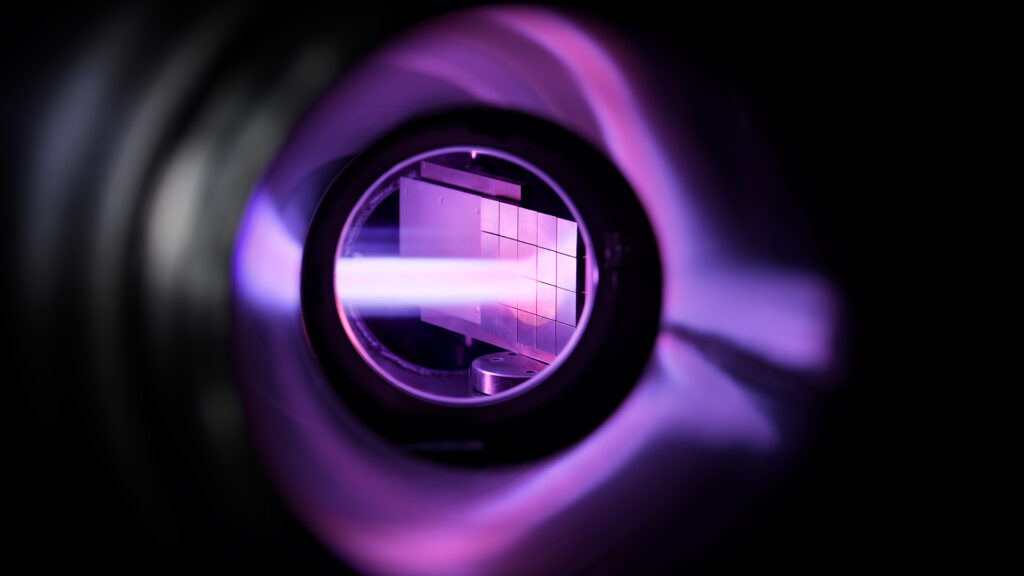

We are in the control room of a research facility in the Netherlands. Magnum-PSI just struck a sample of tungsten metal with a fiery plasma beam of tens of thousands of degrees Celsius. Ail of fast, charged particles fires each square metre of target material with a heat of several tens of megawatts. For hours at a time, just like you’re on the surface of the sun.

Differ’s ion beam facility provides fast ion particles for up to seven different experiments within a building to study the evolution of materials

Magnum-PSI allows future fusion power plant designers to test materials from Tokamaks and Stellarators. These reactors need to confront the task of generating energy from the same processes that move stars. The 15m length assembly of Magnum-PSI stainless steel vacuum chamber is just one of the larger machines used by the Dutch Institute for Fundinia Energy Research (different) to test fusion materials.

Important Questions

Difter visitors are often surprised to learn that the Fusion Research Center does not have its own fusion reactor, explained Hans Van Eck, head of facilities and instrumentation at Differ. Instead, the Institute decided decades ago to specialize in the questions that all participants of the global race must face towards fusion energy. What will happen to the materials in a lifetime in a nuclear fusion reactor? To answer that question, a differently constructed dedicated machine that mimics the conditions in which the fusion plasma is touching the walls of the reactor.

Van Eck said: “Modern tokamaks and stellarators are taller than the entire building, adding support facilities for heating, cooling, instrumentation and electric yards, and the site can fill most of the university’s campus.

Instead, Differ’s specialty facilities occupy a unique position between fusion reactors and tabletop setups run by small university groups. “Our facility answers fusion-related questions at a level of detail that cannot be managed elsewhere,” Van Eck continued.

In fact, a 2024 review of all fusion-related experimental facilities in Europe by the Eurofusion Consortium designated different hardware as “essential.”

World Records

Take tungsten metal for examples of how to contribute to a world of difference. The current material of choice is to protect the interior of the fusion reactor with a melting point of 3,400°C. For example, the ITER project, built by a global consortium of researchers in the southern part of France, announced in 2024 that it would build an entire inner wall from tungsten.

Properly cooled tungsten can handle the incredible heat flow of fusion. However, the prediction is that the year in contact with iter plasma still causes annoyed damage. How much is it? The answer will affect future power plant repair schedules, costs, and planned maintenance. The Magnum-PSI facility is the only device in the world, allowing materials to be exposed to the conditions already anticipated in ITER, or even under more intense conditions than expected in Tokamaks, designed by private companies.

In 2018, the Magnum-PSI team set a world record by exposing tungsten samples to plasma in 18 hours, just as they face during a year of high power operations with ITER. The metal is well lifted and I am sure the material choice is the right one. Hans Van Eck is a classic example of the potential for a small research institution to have a global impact due to smart specialization.

Stop unlocking

Thomas Morgan leads various studies on the interaction of plasma and wall materials. He explained why the laboratory facilities can provide a much clearer image of material degradation than the latest nuclear fusion reactors themselves.

Differ’s Magnum-PSI facility creates plasma conditions as harsh as the surface of the solar to test materials for exhaust in fusion power plants

Morgan said: “Large machines can open vacuum vessels and complete scientific campaigns of dozens to hundreds of shots, and then recover wall materials in different states.” With its complex mix of constantly changing conditions, physicists have concluded, reconstructing how and why material evolves.

In Magnum-PSI, the long robotic arm can withdraw the sample to the analysis chamber after the shot to examine the response to one altered plasma parameter, such as temperature and particle impact energy. And at the new laboratory facility, engineers and researchers can even study their effects during plasma exposure.

The future is live view

Talk to materials scientist Beata Tyburska-Pueschel. Magnum-PSI’s performance seems like yesterday’s news. As the head of a special particle accelerator in the hall next to the laboratory’s flagship plasma device, she runs the ION Beam facility (IBF) in Differ.

IBF can study the deep structure of a material, such as cracks, cavities, or defects in the complete atomic lattice of the material by bounce back the fast particle flow from the sample. Upon increasing the energy, the machine can even mimic the kind of damage caused by the impact of neutron particles from the fusion reaction.

Tyburska-Pueschel explained:

By connecting the IBF to a smaller version of Magnum-PSI called UPP, Differenter can get a live view of how the material changes from second to second while being exposed to Hot plasma. Tyburska-Pueschel described its capabilities being unique in the world, opening up a whole new way of studying how different processes within a nuclear reactor modify wall materials.

A favorite example of Tyburska-Pueschel is two competing processes within the Fusion Reactor Wall. On the one hand, fast neutrons from fusion reactions create defects in the material, such as microscopic cracks and cavities. Meanwhile, hydrogen isotopes from fusion fuels penetrate the metals and fill their vacancy. Do these processes affect each other?

She continued: “If you first create a defect in one experimental setup, then load the material with hydrogen into another machine, you never see how hydrogen occupy the space of the defect. You cannot prevent self-healing as the atoms move around from the fire.

“They want more now.”

From 500 hours of IBF beam times in 2021 and 5 users, the ION Beam facility grew to 3,000 hours and 20 different users in 2025. This is the limit possible for a normal working year, stopping with maintenance and upgrade considerations, but users inside and outside the Institute are looking for more experimental time.

“Our users have got the first taste of what IBF can do.

Outside the world of fusion, the machine is conducting experiments by Differ’s department on electrochemical water division and a consortium examining the material problems of molten salt reactors.

“Now I’m fully booked, so I might need to plan additional shifts to add a second accelerator or apply for a grant.”

Self-healing

One power user of different facilities for fusion materials is Thomas Morgan, a plasma material physicist at the laboratory. After his first experiment at Magnum-PSI, he has now won a grant from the Dutch science funding agency NWO, studying dark hoses in dark hoses along with colleagues at the nearby Eindhoven Institute of Technology (TU/E). Topic: A self-healing layer of liquid metal that protects the inside of a fusion reactor.

This idea seems as daunting as simple as it is. The immediate design of liquid metal cover flows through the mesh below can repair itself from any plasma damage. The physicists and his team built a setup with Differ and Tu/E to study the entire lifecycle of such components.

These facilities range from 3D printers to setups where you can create the ideal support mesh, expose components to plasma and test the best metal for your job. There are even dedicated machines to see how hydrogen isotopes from the fusion fuel are trapped in liquid metals and how they escape in a stable flow or in large destructive bubbles.

Long-term relevance

When asked about what it takes to have a research facility like Differ, Hans Van Eck is clear. Proverb Villages need to design, build, maintain and operate medium-sized facilities in the laboratory. In fact, his technical assistance department makes up a quarter of the entire laboratory. This includes an in-house design office and machinery shop, electronics and software engineers, and dedicated operators. There is a considerable difference from a university group with one technical engineer per 10 scientists research group.

“We need the courage to invest in facilities,” said Van Eck. “I think this is only possible at labs with long-term funding stability.”

Once constructed, the experimental hall facility will continue to be continuously upgraded and improved over the years.

When asked where future facilities will go, Beata Tyburska-Pueschel explained that machines should continue to improve in order to stay at the forefront of science. She said: “My dream is for the ion beam facility to go autonomously. Now it can run the night with pre-programmed instructions. With AI support, the system itself can determine what measurements should be taken to get in order to get insightful data from the user.

This article will also be featured in the 22nd edition of Quarterly Publication.

Source link