By capturing carbon from the furnace off-ges and reverting them to solid carbon feedstocks, the concept of mechalo allows renewable hydrogen to transform the European production of important raw materials such as silicon and manganese.

Metals are essential to our modern lifestyle, but unfortunately, their production also accounts for around 10% of the world’s CO2 emissions. Even if the focus is on scrap and secondary resource recycling, primary metal production is expected to grow in the coming decades. This increase is largely undriven by the role of metals in the green transition, for use in wind turbines, solar panels, etc. For example, electric vehicles (EVs) require more than five times more metal than traditional metals. Counterpart. This is the motivation behind the Mecaro project, which recently granted more than 9 million euros from the European Commission to develop a carbon neutral process for the production of metals such as key raw materials such as manganese and silicon. .

A journey to green metal production

The metallurgy sector is often referred to as one of the so-called “deflation-resistant” sectors. The main reason for this, and the reason why carbon-neutral metal production is so difficult, is that carbon contributes to much more metal production processes than energy sources and cannot be simply replaced by clean energy. This means that even if society attempts to overcome the enormous task of completely converting the energy and electricity sectors into 100% renewable sources, it is not in itself sufficient to separate metal production from carbon. That means. Metal production using today’s processes remains a heavy emitter.

To explain why and introduce mechalo innovations, consider that metals are not usually found in the form of metals in nature, but are combined with other elements of the mineral. In many cases, including manganese and silicon, they are found to be bound to oxygen. To release the metal, oxygen must be removed. This is where carbon comes in.

In a simplified, generalized form, the metal production reaction is written as a reaction between metal oxides (MEO) and carbon, allowing the formation of CO2 with metal.

MEO + C → ME + CO2

Without carbon or another reducing agent, metal production is not possible. Therefore, a typical effort to decarbonize metal production revolves around one or more of the following:

Replace fossil carbon reducing agents with sustainable carbon of biogenic origin. Capture and save CO2. Carbon reducing agents are replaced with non-carbon reducing agents such as hydrogen or electricity.

In the last point, the steel industry in particular has spent a lot of energy developing hydrogen-based steel production. The advantage of hydrogen over carbon is that in metal formation reactions, the by-product of CO2 is replaced by H2O.

MEO + H2→ME + H2O

If the hydrogen used is produced without CO2 emissions, the resulting metal production may similarly contain no CO2. Unfortunately, this approach is suitable for iron, but some minerals do not react with hydrogen and do not abandon the metal. Hydrogen is a stronger reducing agent than carbon.

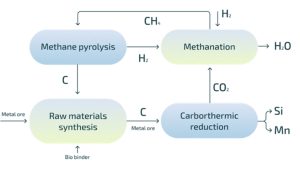

The concept of mechalo solves this dilemma. Its main innovation is that it continues to use carbon as a reducing agent, but rather than releasing CO2 into the atmosphere, it is recycled and reused within the process as a principle called the carbon loop outlined below. Masu.

How does the concept of mechalo work?

The concept of mechalo consists of four steps.

Methanation

Carbon dioxide in the furnace off-gas reacts with hydrogen in the catalytic process.

CO2 + 3H2 Catalyst CH4 + H2O

The hydrogen used is a combination of externally supplied hydrogen and hydrogen produced jointly through the Plasmalysis step.

Plasmalysis

Methane is unstable at high temperatures and decomposes into its components, hydrogen and carbon.

CH4 Energy CS + 2H2

In Mecaro, this process is achieved with microwave plasma, providing maximum energy efficiency. Hydrogen co-produced with solid carbon is returned to the methanation step of the internal hydrogen loop.

Aggregation

Methanation and plasmalysis convert carbon from CO2 to solid carbon, but the result is a very fine powder similar to carbon black, which is not directly suitable for metal production. Therefore, an important point in the mechalo value chain is the aggregation of this powder. The binders needed to provide sufficient strength to aggregates are of biological origin, maintaining the CO2 neutrality of the concept.

Metal production

The final step is to use looped carbon materials and demonstrate that they are suitable for metal production at pilot scale.

Hydrogen as a raw material

Under the concept of mechalo, the core chemical reaction between metal ore and carbon remains the same, creating metal as a product as a by-product. However, when you zoom out and view the entire process/flow sheet, you can see that the material inputs are hydrogen and metal ore (and a small amount of biobinder), and the outputs are metal and water vapor. In other words, the concept of Metalo allows hydrogen to be used as a raw material in the production of metals that have otherwise not been proven to be impossible. Therefore, CO2 emissions from the core processes are eliminated.

A major advantage of the above concept is that, in principle, the core process has not been changed. This means there is no need for a complete overhaul or reconstruction of existing smelters, and significantly increases the probability of rapid implementation and impact.

Furthermore, this concept is agnostic to internal processes, and in principle it can be applied to processes that use carbon, which uses CO2 as a by-product as a raw material. In some processes, it may be easier to use hydrogen directly. However, there are several metals such as silicon and manganese. This is not an option. Within the mechalo there is a dedicated task to consider alternative applications.

Mekaro represents an innovative solution to seemingly unruly problems. It is the use of hydrogen as a raw material for metal production from ores that cannot thermodynamicly react with hydrogen. And this innovation doesn’t depend on recent advances that have been proven only in the lab, with years of development and scale-up before considering industrial implementation. Rather, it is based on a new combination of four established technical principles. Therefore, research challenges remain, but there are no fundamental obstacles to basic research that needs to be overcome. The individual steps of the above four-stage solution are all demonstrated individually at high maturation.

Carbon oxide methanation is an important component in the production of synthetic natural gas from coal or wood and is also used for CO/CO2 removal from process streams of ammonia production. There is no reason why similar techniques cannot be used to convert CO/CO2 to methane in industrial off-jers, but so far similar efforts have typically focused on creating more valuable products such as methanol. Masu. , Carbon Capture and Utilization (CCU) Project.

Similarly, the decomposition of methane into carbon and hydrogen has attracted much attention, particularly as a source of so-called turquoise hydrogen. A commercial factory operates in Nebraska (Monolith), USA.

Carbon black is one of the alternative ingredients the metal industry is investigating as an alternative to fossil carbon. It can be considered CO2 neutral, as if it were sourced from Bio-gas. These tests demonstrate that methane can be used as a source of carbon materials suitable for metal production.

There are individual pieces of the puzzle. The task of Mekaro is to combine pieces and optimize them in one comprehensive process. Scope 1 aims to reduce CO2 emissions by 95% from the production of silicon and manganese alloys. (The reason we can’t aim for 100% is that at present around 5% of our CO2 emissions are due to consumption of fossil-based carbon anodes, which is not within the scope of the mechalo. These ends 5% of the anode material of biological origin, or perhaps non-CO2-generating anode).

If successful, this could change the way metals are produced. Allow Europe to be more self-sufficient with key raw materials: 86% of the EU demand for silicon and 50% of the EU demand for manganese were produced in 2050 with almost CO2-NEUTRALITY, with over 33 million tonnes You can save CO2. Exhaust. This contributes to the EU’s net-zero goal on two axes. It smears the metal production sector with green and at the same time provides the solar panels needed for green transitions and the raw materials needed for wind turbines. Furthermore, the removal of coal in these processes could eliminate 9 million tonnes of coal imports.

The Mecalo brings together 12 partners from around Europe and is coordinated by Norwegian laboratory Sintef. This concept was first developed by Norwegian silicon producer Elchem. Mecaro has joined forces with the addition of French manganese producer Ellamet to focus on the carbon loop as a decarbonisation strategy. The catalytic methanation process is developed by JM in collaboration with SINTEF, whereas Sakowin Green Energy is responsible for the methane trait system. ITPE in Poland and Gratt in Germany are key partners working on aggregation, while the other partners are PDC (process modeling and optimization) and BTG (biobinder production). LCA and Italian ETA on communications and outreach activities.

The project began in October 2024 and runs until March 2028.

The project receives funding from the European Union’s horizon research and innovation action under grant agreement number 101177480. Executive Agency (HADEA). Neither the European Union nor the permitting authority can be held liable for them.

reference

https://www.iea.org/data-and-statistics/charts/minerals-used-in-electric-cars-pared-toconventional-cars

This article will also be featured in the 21st edition of Quarterly Publication.

Source link