Ellie Gabel, Associate Editor at Revolutionized, explores advance precision production methods for micro-manufacturing, automation and 3D printing for small and accurate components.

Micro-manufacturing is an increasingly popular manufacturing technology that produces small items, often at millimeter scale, to meet accurate tolerances.

Many advanced manufacturing technologies make this option more accessible and accurate, improving medical devices, electronics and more.

Automates the quality control of small parts

Inspection is important in micromanufacturing and ensures that the product meets the specifications of the client.

Human involvement is still necessary, but many manufacturers are investigating viable ways to reduce manual processes that can take too long or cause errors. That was the case of Kif Parechoc, a Swiss producer of watch parts and subassemblies.

The reader wanted a one-click system to detect a large number of parts and import measurements into an internal database.

However, due to the challenging production environment and the complexity of measuring many small parts at high speed, they realized that the technology employed would require machinery capabilities.

The company’s smallest parts are only 20 microns thick and are less than a few millimeters in diameter.

Kif Parechoc previously conducted inspections and measurements at another cleanroom facility, and decision makers intended to move these tasks to the production floor.

The automated solution selected allows for that change and allows the company to rely on a single machine to automatically clean, dry and measure precision parts.

The machine has advanced optical equipment and allows parts to be automatically placed for inspection, so operators do not need to manually adjust.

Furthermore, since 360-degree measurements are required, there is no possibility of perspective distortions that can cause inaccuracies that people have to correct later.

This example explains why many industries first implemented automation and then increased their production by over 5%.

Thoughtful decisions about how, when and why automation is used can help you maintain high quality levels while increasing productivity.

Using small parts can be a pain for humans, but these tasks are perfect for special machines that reliably function in busy environments.

Automation can also increase manufacturer diversity, allowing businesses to offer a wide range of small components to clients with specific needs.

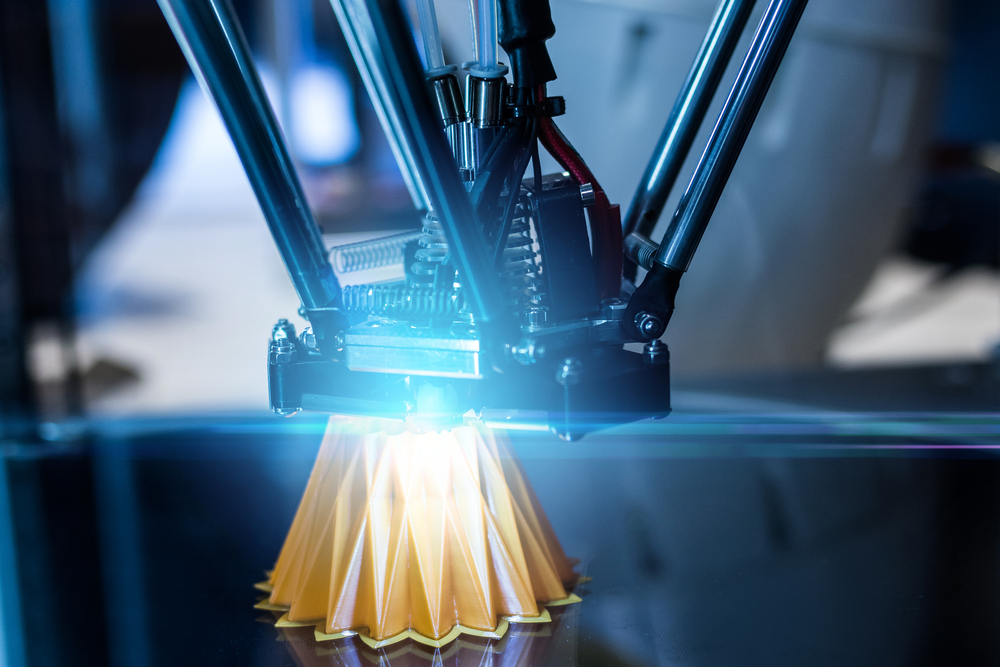

Achieve sub-micrometer accuracy with a 3D printer

3D printers have contributed to shortening production times and increasing flexibility, especially when manufacturers need parts that are difficult to find.

Some companies install 3D printers in production facilities to produce spare components when needed.

Sometimes people believe that in theory the small parts work well, but they want more evidence before they start a larger production run.

3D printers can give its guarantee if the manufacturer uses them to prototype microscale parts. Although product-specific variations exist, 3D printed options cost an average of $100 and are perfect for those looking to design several prototypes.

Some 3D printing companies specialize in small, ultra-high receiving components, leveraging new but growing market segments.

One example is Scrona AG, which uses additive manufacturing for semiconductors, displays, and other components in demand. The company’s innovative approach uses electrostatic forces to draw ink from the nozzle and lead it to the printer bed.

This electrostatic discharge method is ink dependent, allowing manufacturers to use a variety of viscosities, ranging from salt solutions to waxes. Furthermore, this is a fast method for producers who want to maintain high power while investigating this technique.

Users can create multidimensional items with lateral dimensions below 1 µm and control thickness at the nanometer scale.

Create small devices to improve medical outcomes

People who make products inside the body must be particularly accurate in their assessments, as unintended shortcomings can be life-changing.

However, progress in micro manufacturing has come a long way, and some health professionals believe that extreme devices can help patients live longer and healthier lives.

Those inside the body can supply certain medications to the exact locations where they need them, potentially reducing many of the severe side effects of interventions such as chemotherapy.

Similarly, these small works help scientists learn more about the effects of new drugs on the body, indicating whether these treatments are safe for widespread use.

In one case, the researchers developed a microbot with a structure of about 30 microns in diameter and delivered the drug to rats with bladder tumors.

This experiment was given four treatments to rodents over a 21-day period. The results showed that providing medicines with small robots is more effective in reducing growth size than traditional methods.

Based on that success, the team believes their work can improve the way people receive their medicines and even bring about robot-based surgery.

They will not test human innovation for a while, but this early work is important to show which decisions are most likely to be rewarded in the real world.

Promotes the accuracy of small products

People working in previous generations of manufacturing have discovered that the products are less accurate as sizes decrease.

However, these fascinating examples show that advanced technologies such as 3D printers and automation allow small items to be created without sacrificing accuracy.

These ongoing micromanufacturing outcomes encourage researchers, manufacturing executives and others to break boundaries and pursue new options to improve the lives of people and increase the competitiveness of businesses.

Additionally, their processes inform peers and other stakeholders of what is best for them, creating a foundation for further investigation.

Source link