The pursuit of fusion as an infinite, sustainable energy source has made a major leap with a new breakthrough in lithium-6 extraction.

Scientists have developed a mercury-free method for separating lithium-6, an important component of fusion fuels.

This innovation eliminates the need for dangerous mercury-based processes while maintaining efficiency and addresses long-standing challenges in fusion energy research.

This development is becoming clearer on the path to commercial integration, providing hope for a cleaner, more sustainable future.

The need for lithium 6 in nuclear fusion

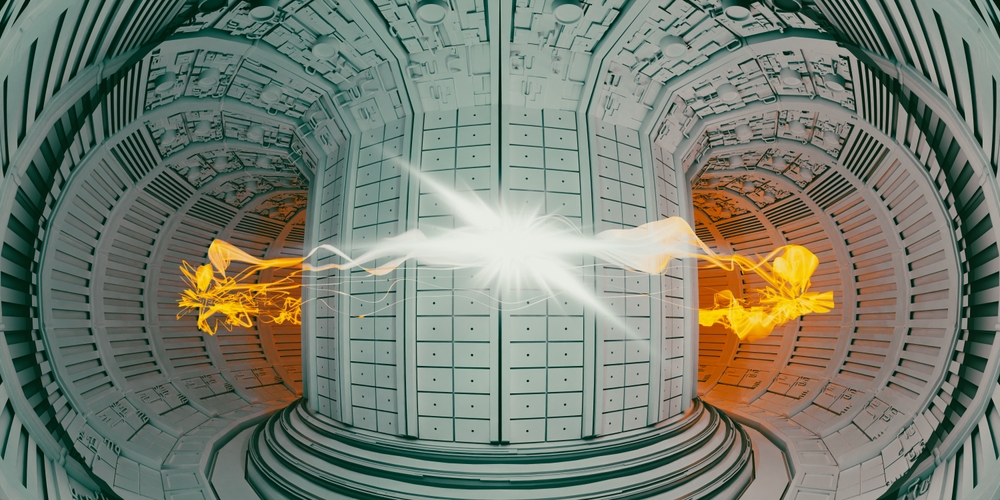

Nuclear fusion, the process that moves the sun, is widely considered a clean, virtually infinite energy future.

However, one of the key challenges in achieving practical fusion energy is to source lithium-6, a key component of the fusion reaction.

Traditional methods for separating lithium-6 rely on the Colex process using liquid mercury. It is a highly toxic substance that has been banned in the United States since 1963 due to environmental and health concerns.

Since the ban, US researchers have relied on a decline in lithium-6 reserves from the Oak Ridge National Laboratory in Tennessee.

A new mercury-free method of separating lithium-6 is essential to ensure a stable and scalable supply for future fusion reactors.

Safer and more sustainable way to extract lithium 6

Researchers at EthZürich and Texas A&M University have discovered an alternative method for lithium-6 separation that eliminates the need for mercury while maintaining high efficiency.

The breakthrough happened unexpectedly as the team was working on membranes to cleanse “production water,” a by-product of oil and gas drilling.

These membranes demonstrated a strong ability to selectively capture lithium, further investigating the potential for lithium isotope separation.

How mercury-free processes work

This new method utilizes a material called zeta oxide (ζ-V2O5), a progressive inorganic compound known for its unique lithium binding properties.

This material features a one-dimensional tunneling structure that selectively traps lithium-6 ions more effectively than lithium-7 ions.

To test its efficiency, researchers designed an electrochemical cell with a ζ-V2O5 cathode. When lithium-containing aqueous solutions were pumped into cells under applied voltage, lithium ions migrated towards the negatively charged ζ-V2O5 matrix.

Due to differences in mass and movement, lithium-6 was preferentially captured, while lithium-7 remained in solution. The process also provided a visual indicator of lithium absorption as the material changed color from bright yellow to dark olive green.

Mercury-free competition results

This study demonstrated that a single electrochemical cycle can concentrate lithium 6 by 5.7%. The process must be repeated approximately 25 times to reach the purity level required for fusion fuel (at least 30% lithium-6).

An even higher concentration level of 90% requires approximately 45 cycles. These results provide new methods, from an efficiency standpoint, but no dangerous mercury components.

Expand for industrial production

Although this research is still in its early stages, scientists are optimistic about expanding the process for industrial applications.

The team is actively working to overcome engineering challenges, including optimizing flow loop systems to ensure continuous and cost-effective lithium-6 production.

This mercury-free approach not only paves the way for safer lithium-6 extraction, but also has potential applications for other isotope separations, including improvements to radioactive materials.

Future of fusion fuel

As fusion research accelerates, demand for sustainable lithium-6 supply will only increase.

Developing eco-friendly, scalable, and cost-effective separation processes is an important step in making fusion energy a reality.

This breakthrough could mark a turning point for global pursuit of a sustainable, carbon-free energy future.

Source link