CIRBA Solutions emphasizes the importance of collaboration and strategic investment to establish stable and competitive supply of important materials in consideration of the growth of the battery cycle industry.

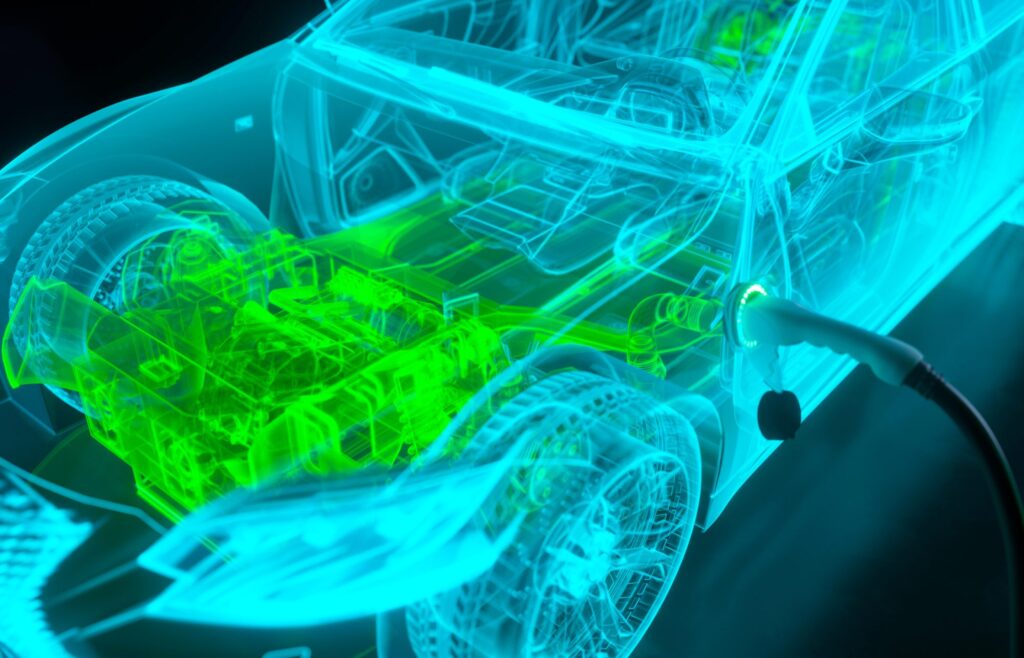

As the battery industry continues to grow, the importance of developing a raw material supply chain of a closed loop has become more important than ever. The important material processing industry, which manufactures the new battery -grade metal, is important to secure a supply chain, enhance global competitiveness, and develop advanced energy. The main growth departments around the world are battery cycle.

Development of the global battery cycle industry

The historically known transition from the battery cycle has shifted to sophisticated chemicals, and the cector capacity is still smaller than the virgin material, so it has not been noticed in the market. However, if there is no new path of important materials, you will not be able to meet future demands, and the transition requires investment. The recycling industry does not prosper without a acceptable investment rate. However, the global authority that controls the market today uses the influence to guarantee that the control is powerful and powerful. Investing in these areas needs to be considered attractive to develop a new road for a finite source.

Currently, 85 % of rare earth metals are sophisticated in China today, 70 % of battery -cats and 70 % of lithium -ion cells. An important mineral sophistication that the United States and Europe are delayed. As a result, when purchasing the market, there is an unprecedented inflation of battery acquisition costs. This has been overwhelming for customers, including the long -term execution of sectors on a global -scale sector, for long -term Giga Factory and original equipment manufacturers (OEMs).

Without a new market intervention, China will be more powerful with important mineral sector. In order for a new market to be competitive, it is necessary to enable highly profitable returns and attract investment.

Battery cycle industry growth

Certainly, the European Union (EU) has advanced to increase the recycling of battery and improvement of materials by maintaining important materials in Japan and adopting new battery regulations. By 2030, the United States has more than 1,200 GWH, and cell makers, Gigafactory, and original equipment manufacturers need more raw materials than currently available to meet the expected battery demand ((). Benchmark Mineral Intelligence).

In order for this sector to continue the growth orbital, both supply chains, public institutions and private companies require more collaboration to invest in the market cost of these materials in Japan. You need to take action now to ensure the future security of this industry.

Potential solution

All industries face unique issues, and the battery cycle sector is no exception. The procurement of important minerals and the diversification of the supply chain are national security issues that affect many countries, and to be competitive in important material categories: You need to evaluate.

A strategic and shared approach between the public sector and the private sector for investing in the entire battery for the entire battery for the existing mature market. The method of promoting balanced market consideration, from battery acquisition costs to processing materials such as sulfate, shows positive returns of investment capital. Increase investment throughout the battery supply chain. This can be caused by changing the industry standard and consistency with other harmful waste treatment, including the payment of dangerous materials removal.

Diversifying important mineral supply chains is important to ensure the most efficient use of these metals. In addition, we will quickly increase market availability.

Conclusion

Companies based in North America and Europe are greatly dependent on the import of raw materials such as lithium, cobalt, nickel, and manganese, and supports the needs of battery and the priority of energy transition.

To diversify these materials sourcing in Japan and create a more stable supply chain, you need to set a clear expectation in today’s market. As a result, the industry can now prosper in the future and create a diversified market.

It is essential to cooperate with both public and private entities. Without a reasonable market price, this sector is not attractive for investment. And more importantly, the battery ends in the management of landfills or foreign countries with concerns.

The recycling and recovery of these materials is possible today if you fully support the new and important mineral roads, including the recycling of the battery.

reference

https://www.csis.org/friendshoring-lithium-battery-supping-chain-chell CHINA%20 Dominates, and%203%20 Percent % 20 % 20anodes

This article is also published in the 21st edition of Quarterly Publication.

Source link