The European Commission has announced funding for six cutting-edge EV battery manufacturing projects in a bold move to accelerate green transitions and secure the future of the industry.

This groundbreaking investment, sourced from the EU’s emissions trading system through innovation funds, has taken a major step in promoting Europe to become a global leader in EV battery production.

As demand for electric vehicles surges and the world moves away from fossil fuels, the EU is doubling homemade innovations to reduce emissions, increase competitiveness and reduce reliance on imported technologies.

Commenting on the funding, Climate Commissioner Wopke Hoekstra continues to grow cleanly with zero zero.

“The call to each innovation fund is demonstrating the key role of the EU emissions trading system, innovating and adapting to our industry.

“This first phone call dedicated to batteries shows its commitment to providing an industrial action plan for the European automotive sector.

“We want to thrive EU battery manufacturing thanks to innovative and clean technology.

Funding causes battery charging on the continent

The grant is the result of the EU’s first dedicated battery call launched in December 2024 under the Innovation Fund.

Of the 14 submissions from eight countries, six projects were selected after a rigorous evaluation by independent experts.

The selection criteria focus on innovation, reduction in GHG emissions, technical and financial readiness, replication potential, cost-effectiveness and strategic contributions to EU supply chain resilience.

These projects are in line with clean industrial contracts and the industrial action plan for the European Automobile Sector, and are part of a broader EUR 3 billion EU initiative to strengthen the European battery ecosystem.

Six billing-leading projects

The six selected projects to begin operations before 2030 are:

Accepted: Automotive Cells Company’s European Production Takeoff (France) Agathe: Verkor’s Advanced Gigafactory (France) CF3_AT_SCALE: Cellforce Group’s High Performance Manufacturing Scale-Up (Germany) Novo One: Novo Energy’s Gigaactory Project (Sweden) WGF2G: Lecchanché’s 2 gwhwwh willtat 46ineu: LG Energy Solutions Cylinder Cell Production Expansion (Poland)

The projects are projected to add annual production capacity of approximately 56 GWH of EV battery cells and reduce greenhouse gas emissions to 91 million tonnes of CO2 over the first decade.

Innovation meets sustainability

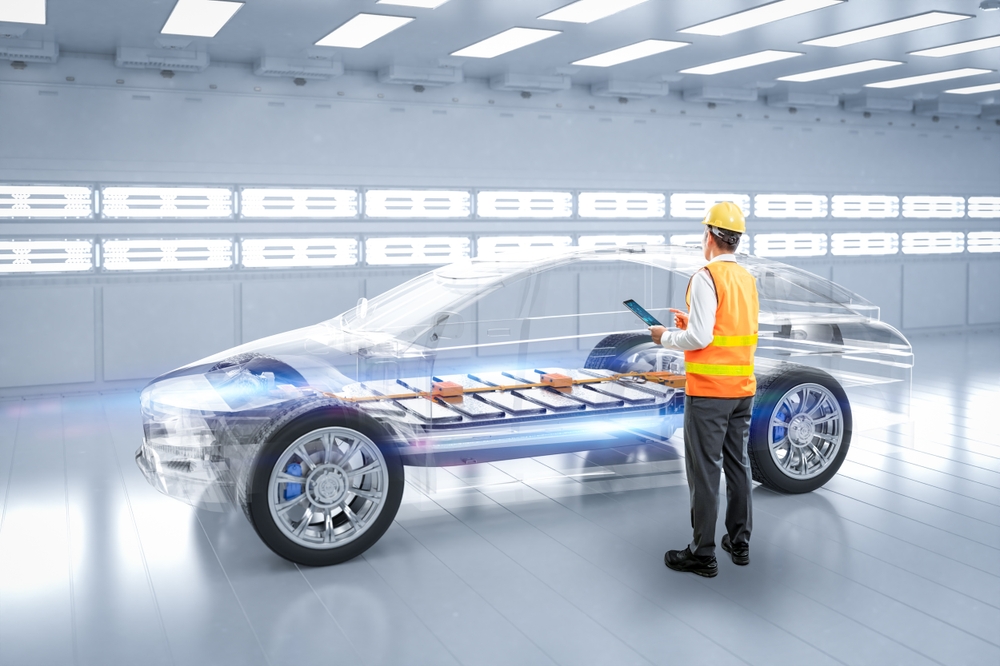

Beyond the increase in output, the selected initiative prioritizes sustainability and cutting-edge EV battery manufacturing.

Each project integrates next-generation technology with sustainable processes, contributing to the EU’s broader climate neutrality objectives.

These Gigafactories are not just assembly lines, but hubs of innovation focused on reducing carbon footprints for both batteries and manufacturing processes.

Support covers both capital and operational expenditures, with gradual expenditures linked to project milestones.

Why is EU battery manufacturing important?

Ramp up in EV battery manufacturing is a strategic need. As global competition for clean energy technologies intensifies, Europe’s reliance on imported battery cells, primarily from Asia, shows economic and geopolitical vulnerabilities.

By investing in domestic EV battery production, the EU will reduce its dependence on external suppliers, protect its supply chain and protect the automotive industry from future disruptions.

Additionally, the initiative positions Europe as a leader in clean technology and advanced manufacturing, promoting high-quality employment and promoting regional economic growth.

With strengthening homemade battery production, the continent can meet the burgeoning demand for EVs, driven by tightening emissions regulations and increasing consumer adoption.

Without a robust internal battery supply, Europe risks falling behind in the transition to sustainable transportation.

Roads for EU battery production

The agreement between the project leader and the European Climate, Infrastructure and Environmental Executive Agency (CINEA) is expected to be finalized in the third quarter of 2025.

Once construction and development begins, these projects will serve as the basis for Europe’s push towards industrial decarburization, innovation and economic resilience.

With a bold investment in the manufacture of EV batteries, the EU is laying the foundation for a cleaner, stronger, and more self-sufficient future.

Source link