Pioneering safe and sustainable biobased and biodegradable plastics for a circular future.

The proliferation of waste littered in open environments and the subsequent pollution from harmful substances it releases, especially from plastic materials, has escalated into a global emergency. This crisis severely impacts soil and water quality, as well as biodiversity in both terrestrial and marine ecosystems. In this context, the biodegradability of materials and products for targeted applications could offer viable end-of-life solutions, provided biodegradation occurs safely and sustainably, whether in open environments or under controlled conditions. Biobased and biodegradable plastic products (BBpPs) are emerging as a crucial part of the solution to this pervasive issue. However, their safe and sustainable deployment necessitates addressing several key challenges.

Critical challenges in biobased and biodegradable plastics deployment

Ensuring lifecycle alignment with circular economy principles1,2:

Achieving the full potential of BBpPs hinges on aligning their entire lifecycle with circular economy principles. This includes utilising renewable feedstocks and establishing circular production processes to maximise positive environmental impacts.

Tailored design for end-of-life routes and biodegradation:

Some products, due to their propensity for littering or specific use scenarios (e.g., agricultural mulch films, humanitarian aid products), are inherently difficult to collect at their end-of-life. While biodegradable materials offer a potential solution in these contexts, their use in open environments remains challenging. For new plastic designs, biodegradation must be conceived as a ‘system property’, rigorously considering material characteristics, the receiving environment, and an evidence-based timeframe to prevent environmental harm.

Furthermore, current biodegradation definitions typically only account for the organic polymer component, overlooking other substances like inorganic additives, adhesives, and coatings, which can undermine environmental footprint claims and affect polymer biodegradability. This oversight risks the accumulation of harmful substances in ecosystems, underscoring the urgent need for polymers designed with ‘safe programmed biodegradation’, incorporating only safe substances.³

Reproducibility and comprehensiveness of biodegradation assessment standards:

Current standard test methods for assessing plastic biodegradation in open environments suffer from weak reproducibility and often fail to encompass all environmental factors and material properties that influence the biodegradation process. These methods require supplementation with standard specifications, such as defining pass levels for each environmental compartment, which are still under development. Consequently, existing certifications (e.g., ‘marine degradable’) need updating to avoid consumer confusion.⁴

Establishing an enabling environment and preventing misleading claims:

An enabling environment is crucial to ensure that BBpPs and their externalities do not negatively impact human health and the environment, while simultaneously fostering the adoption of biobased and biodegradable value chains. While Safe & Sustainable by Design (SSbD) approaches are recognised as key instruments for green industrial transition, further operationalisation of the SSbD framework is needed. Moreover, labelling a product as ‘biodegradable’ must not mislead consumers or encourage improper disposal that leads to plastic littering. Labels must therefore be based on new or adapted certification schemes that contextualise biodegradability claims and support user information efforts.

A particularly relevant application where BBpPs can significantly mitigate pollution is in single-use items within humanitarian contexts (e.g., natural disasters, armed conflicts), where robust waste management systems are often unfeasible.⁵ Plastic waste, predominantly from healthcare and packaging, is a major contributor to uncontrolled waste in these settings, driving a growing awareness of its environmental impacts.⁶

In particular, high amounts of wound dressing wastes are generated each year in hospitals and homes (only in the UK, 16,680 tonnes of waste annually.)⁷ This waste cannot be recycled due to inherent biological hazards. In emergency situations, when they are released into the environment, they not only produce plastic pollution but also, if these wound dressings contain antibiotics, these are released into the environment,⁸ increasing contamination in addition to their implications for antibiotic resistance, which is one of the greatest global health threats.

Consequently, in recent years, some studies have emerged aimed at developing safe biodegradable wound dressing materials. In such cases, safe biobased and biodegradable plastics can serve as an effective remediation measure.

The polymer family of polyhydroxyalkanoates (PHAs), illustrated in Fig. 1, is highly promising for applications intentionally released into natural environments. They offer desirable functionalities, are biocompatible, synthesised by microorganisms, and are fully biodegradable in relevant environments, including soil, freshwater, and marine settings, without causing microplastic pollution.⁹ Within the PHA family, PHBV (poly(3-hydroxybutyrate-co-3-hydroxyvalerate)) copolymer stands out for its modulable flexibility, while PHN (3-hydroxynonanoic acid) has recently emerged as a promising material for biobased and biodegradable adhesives and coatings due to its elastomeric properties.

However, PHAs currently occupy small niche markets due to processing difficulties and high costs. Furthermore, their biodegradation rates depend on product form, processing, formulation, and the specific environment they end up in, necessitating further research to ensure safe biodegradation in diverse contexts.

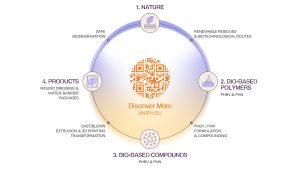

The ANIPH project: A PHAs-based solution for a circular future

The ANIPH project aims to revolutionise material science by demonstrating the development of a diverse range of polyhydroxyalkanoates (PHAs), including both semicrystalline PHBV and elastomeric PHN variants. Our core objective is to integrate circularity strategies and Safe and Sustainable by Design (SSbD) approaches throughout their lifecycle. These PHAs will feature programmed biodegradation while delivering the necessary technical performance for two key use cases: modern wound dressings and recyclable water barrier packaging. Crucially, these materials will be fully biodegradable in all relevant natural environments (soil, freshwater, and marine).

The biodegradation capabilities will be meticulously controlled and ‘programmed’ across multiple stages: during PHA production, formulation and compounding, and conversion (via 3D printing to develop the wound dressings and cast/blown extrusion in combination with spray coating to develop the packaging). To support these ambitious goals, an artificial intelligence (AI) predictive tool will forecast biodegradation, material properties, and ecotoxicity, while a digital traceability tool will ensure transparent tracking of materials and products throughout the entire ANIPH value chain.

Groundbreaking PHAs-based solutions for key challenges

ANIPH proposes a cutting-edge PHAs-based solution, demonstrated through two critical applications, wound dressings and their corresponding flexible packaging, designed to overcome pressing environmental and material challenges:

Enhancing circularity across ANIPH’s lifecycle, Fig. 2

The project prioritises circularity at every stage:

• PHAs production: We utilise renewable residues as feedstock, specifically agrifood waste such as brewery and agricultural residues, and actively recirculate waste streams within the production process.

Ecodesign and manufacturing: ANIPH significantly reduces industrial waste through optimised processes. This includes the use of 3D printing for wound dressings and implementing recycling strategies for pre-industrial waste generated during cast/film extrusion for packaging.

Tailored end-of-life routes: For packaging, we enable high-quality recycling by developing monomaterial products, directly substituting conventional, non-recyclable multimaterial solutions. Simultaneously, we ensure safe biodegradation in open environments where appropriate.

Programming the biodegradation of PHA materials and products

ANIPH rigorously controls key factors influencing biodegradation throughout the entire development lifecycle:

Production stage: We precisely manage PHA polymer composition and crystallinity by optimising feedstock selection and production conditions.

Formulation and compounding: Biodegradation is further modulated by carefully controlling crystallinity and water adsorption capacity using safe, biobased, and fully biodegradable additives, including innovative PHA adhesives and coatings.

Manufacturing: We leverage advanced manufacturing techniques, including 3D printing for wound dressings and cast/blown extrusion with spray coating for flexible packaging. This allows us to control the surface-to-volume ratio and incorporate sustainable medical additives like probiotics and cellulose as safe alternatives to hazardous antibiotics.

3. Innovative biodegradation assessment

ANIPH employs a robust three-tier testing scheme (Fig. 3) to ensure the reproducibility and accuracy of biodegradation assessments. This comprehensive scheme includes evaluating biodegradation under environmentally relevant conditions, assessing material lifetime, persistence, residence time in specific environments, and analysing overall environmental effects through synergistic approaches.

4. Contributing to an enabling environment

ANIPH is committed to fostering a supportive ecosystem by:

Developing novel Safe and Sustainable by Design (SSbD) approaches that integrate environmental, social, and economic assessments.

Actively contributing to Information and Labelling Systems (ILSs). This includes proposing standard specifications, testing methods, communication standards, and certification schemes/labels for bio-based and biodegradable plastics (BBPs), thereby empowering informed decisions for both consumers and industry.

Digital empowerment and future impact

Throughout its lifecycle, the ANIPH project leverages the transformative benefits of AI-based and digital tools. AI-powered tools enable the accurate prediction of material properties, ecotoxicity, and biodegradation profiles. An integrated ICT platform will further enhance this by featuring:

A Traceability tool to ensure secure data transfer across the entire value chain.

An Evaluation & Decision tool to support SSbD-based choices.

A Public tool designed to communicate verifiable information and boost public acceptability of these innovative materials.

With EU funding, ANIPH developments are projected to achieve Technology Readiness Level (TRL) 4-5 by the project’s conclusion in 48 months. This will establish a safe and sustainable PHAs-based value chain from production through to a safe end-of-life. By generating an accurate database of PHA biodegradation materials and products through its innovative assessment methods, ANIPH will lay the groundwork for new industry standards and certification schemes/labels, while simultaneously increasing overall awareness and acceptability of these truly circular solutions.

ANIPH is formed by a multidisciplinary consortium that brings together eight partners from six countries, each with specific expertise to advance the field of biobased and biodegradable plastics. The group includes key players in research and technology, represented by CETEC, which also coordinates the project, the Agricultural University of Athens, and the University of Granada. Industry expertise comes from CETEC Biotechnology and Terraverdae, both producers of polyhydroxylakanoates (PHAs), and GO! PHA is the global PHA organisation representing the PHA sector. To ensure a well-rounded approach, the consortium also includes social science experts from Knowledge Value Consulting and communication and dissemination specialists from ICONS. This diverse and experienced team is poised to make significant contributions to the bioplastics sector.

References

Bologna Business School. (2025). Bio-based and biodegradable plastics: an opportunity for a circular and sustainable bioeconomy?

Ellen MacArthur Foundation. (n.d.). What is the circular economy?

https://op.europa.eu/en/publication-detail/-/publication/0c0d6267-433a-11eb-b27b-01aa75ed71a1/language-en, «European Commission, Directorate-General for Research and Innovation, Biodegradability of plastics in the open environment, Publications Office of the European Union, 2021

R. R. A. Silva, C. S. Marques, T. R. Arruda, S. C. Teixeira, y T. V. De Oliveira, «Biodegradation of Polymers: Stages, Measurement, Standards and Prospects», Macromol, vol. 3, n.o 2, pp. 371-399, jun. 2023, doi: 10.3390/macromol3020023.

https://logcluster.org/en/blog/wrec-project

Biodegradability Testing of Compostable Polymer Materials», en Handbook of Biopolymers and Biodegradable Plastics, Elsevier, 2013, pp. 213-263. doi: 10.1016/b978-1-4557-2834-3.00011-2.

J. R. Lawrence et al., «Community-Level Assessment of the Effects of the Broad-Spectrum Antimicrobial Chlorhexidine on the Outcome of River Microbial Biofilm Development», Appl Environ Microbiol, vol. 74, n.o 11, pp. 3541-3550, jun. 2008, doi: 10.1128/aem.02879-07.

A. Paloyan et al., «Biodegradation of polyhydroxyalkanoates: current state and future prospects», Front. Microbiol., vol. 16, feb. 2025, doi: 10.3389/fmicb.2025.1542468.

Please note, this article will also appear in the 23rd edition of our quarterly publication.

Source link