The Global Impact Coalition outlines important considerations for tackling the destruction of PFA in industrial water systems.

Have you heard of per and polyfluoroalkyl substances (PFAs)? Perhaps the nickname “Forever Chemicals” rings the bell. These synthetics are frequently headlined, from the US administration’s recent $15 million investment to the $15 million investment to study PFA on US farmland to portrayals in the 2019 film Darkwaters, starring Mark Ruffalo as environmental lawyer Robert Bilot. To develop a viable solution, you first need to understand the history, use, and impact of these permanent materials.

What is PFA?

There are many different types of PFA. According to the European Chemical Organization (ECHA), PFA is a group of artificial chemicals characterized by the presence of at least one fully fluorinated methyl (CF3-) or methylene (-CF2-) carbon atom. These PFAs are characterized by strong carbonfluorin bonds. The most stable bonded carbon can be formed from at least two fluorine molecules attached to the same carbon molecule. This extreme stability is the resistance to degradation to PFA and its distinctive properties: heat resistance, chemical inertness, and water and green repellency.

Polymer PFA, or fluoropolymers, were first discovered in 1938 by Roy J. Plunkett, a young DuPont chemist, in an effort to develop safer refrigerants. This compound belongs to the group of long chain PFAs, which can contain up to 100,000 carbon atoms. To scale up the production of Teflon, PFOA (Perfluorooctanoic acid), composed of eight carbon atoms, was used as a processing aid to avoid explosions caused by the chain reaction required to create Teflon.

All of these have certain grease or water resistant properties and are difficult to break down. Thanks to its non-interactive properties, PFA is widely used across sectors, including major industrial sectors such as aerospace and defense, automotive, aviation, food, textiles, construction, electronics, healthcare, and more. Examples include corrosion resistant coatings, water leaf-like fabrics, and fire foams. Polymer PFAs (fluoropolymers) are essential materials used in many high-tech applications that are essential to modern life and when PFAS alternatives are currently unavailable.

Environmental and health impacts

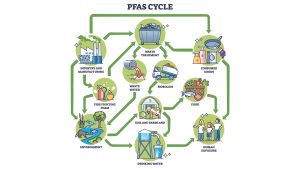

The extremely stable that makes PFAs commercially valuable makes them environmentally sustainable. PFA does not break naturally, and some PFA compounds can travel long distances through air and water. Today, small functionalized PFAS molecules are found in some of the world’s most distant parts, from Himalayan rainwater to Antarctic snow. Surprisingly, the study found detectable PFA levels in the blood of 99% of the world’s population. 7,8

However, being does not always mean harm. Due to physicochemical properties, polymer PFAs such as Teflon (PTFE) and other fluoropolymers are not biologically available. This means that it has limited ability to interact with biological systems and pass through the body without being absorbed. However, small functionalized PFAS molecules containing surfactants and derivatives with similar structures are biologically active due to their structural similarity to natural fatty acids. These compounds can accumulate in the body over time and are linked to a variety of health issues. 9 Wildlife is also affected. PFA has been found in species ranging from polar bears to turtles, causing serious ecological concerns. As evidence grows, so does regulatory pressures to address this issue globally.

Industrial Results

From an industrial perspective, PFA presents unique challenges, particularly in the waters of industrial processes. Their resilience makes traditional water treatment processes almost ineffective. Long chain PFAs (perfluorocarboxylic acids and perfluorosulfonic acids with chain lengths C8-C14 and related compounds) are more tightly regulated and slightly easier to remove. However, short-chain PFAs (perfluorocarboxylic acids and perfluorosulfonic acids with C <8) are more mobile and more difficult to eliminate, resulting in great environmental and health concerns. (See Figure 2)

Because PFA is found in almost all water streams, industrial facilities that use large amounts of processed water, commonly withdrawn from rivers that can be contaminated by PFAS derivatives, face several risks. Without proper treatment, PFA can contaminate the product. This is a serious problem for sectors such as food and medicine. Infrastructure is also at risk. PFA accumulates in pipes, tanks and waste sludges, complicating safe disposal and management during cleaning campaigns.

However, if PFA is successfully removed and destroyed at large sites using large amounts of process water, PFAS levels can drop dramatically in proximity to the site. Such a successful solution could require a combination of technology and techniques tailored to a particular location and a wastewater configuration that could vary from production line to production.

Find a solution

Technological innovation is important. More mature approaches, such as advanced filtration (eg, reverse osmosis, nanofiltration), adsorbent materials, and more innovative approaches involving thermal or electrochemical breakdown, are all under investigation. However, there is currently no single technology that offers a solution that fits one size. Further research and testing is required to find the most appropriate way to scale the most promising technologies and combine existing technologies in a local context.

The most widely used treatment options today include granular activated carbon (GAC), ion exchange resin (IX), and reverse osmosis (RO) or nanofiltration (N). Reverse osmosis and nanofiltration effectively remove both types using high-pressure membranes, but can be costly and energy-intensive. Importantly, these methods separate PFA rather than destroying it. It raises questions about long-term destruction.

Several emerging destruction technologies, such as electrochemical oxidation, cold plasma treatment, or supercritical water treatment, are attracting attention. 13They aim to completely destroy the carbon-fluorin bonds, thereby mineralizing PFA into by-products such as Co₂, HF, and water. While some early tests have shown promise, most remain in the pilot stage and are not yet ready for a wider deployment.

GIC’s PFAS Destruction Project

Recognizing the scale and urgency of the PFAS challenge, Global Impact Coalition (GIC) is leading a collaboration to identify, test and expand viable PFAS destruction solutions for industrial process water. Through this multipartner project, GIC aims to collaborate on co-pilots of performance for a variety of technology, tailored industrial solutions, and solutions at operational sites.

The focus is on approaching short chain PFA. This is more mobile and more difficult to eliminate. Using the shared infrastructure and expertise of GIC members, this project aims to test technology on real-world industrial sites. The goal is to generate actionable insights and accelerate progress towards a safe, scalable, and cost-effective PFAS treatment system.

Combining technical knowledge, industry access and global collaboration, GIC helps bridge the current knowledge gap and is working to tackle the Global PFAS Challenge.

Call the innovator

Are you working on technology to destroy short-chain PFAs in water? I want to know more! Reach out to connect to the Global Impact Coalition Innovation Ecosystem.

reference

Tom Parking. The Trump administration yanks for $15m to study PFA on US farms: not stupid, it’s evil. Guardian, July 11, 2025. Lauren Corey. Dark Waters: Unsung Todd Haynes Legal Drama is a master class for Dread. The Guardian, February 20th, 2024. EHCA, European Chemicals Agency, Overview of Polyfluoroalkyl Materials (PFAS) (PFAS and Polyfluoroalkyl Materials (PFA) – ECHA) RB Seymour and GS Kershenbaum. Plunkett, RJ “The History of Polytetrafluoroethylene: Discovery and Development”, High-Performance Polymers: Its Origin and Development. Proceedings of the Symposium on the History of High Performance Polymers at the American Chemical Society Conference of New York, April 15-18, 1986. New York: Elsevier, 1986. Rudy Molinek. Teflon’s long, strange history, indestructible products seem to be stuck with anything. Smithsonian Magazine, August 20, 2024. Sharon Ginap. PFAS “Forever Chemicals” hurts wildlife around the world: Research. Monga Bay, September 26, 2023. HBM4EU. Policy Brief PFA. European Human Biomonitoring Initiative, June 2022. KuklenyikZ, Reidy JA, Needham LL. , Calafat AM, Wong Ly. “US polyfluoroalkyl chemicals: data from the 2003-2004 National Health Nutrition Survey (N.HANES) and N.HANES 1999-2000. Environmental Health Perspective, November 2007, Dewitt JC, Lau C NG C, Smith JS and RobertsSM. Ducatmanse, ducatmanse, ducatmansm. Human Health Status: March 2021 Environmental Working Group Fact Sheet: Treatment Options for Removing PFA from Drinking Water in April 2024, Idtechex, Emerging PFAS Destruction Technologies, Water Industry Journal

This article will also be featured in the 23rd edition of Quarterly Publication.

Source link