Weaver Labs offers smarter and more effective PFA removal at lower lifecycle costs.

Increased awareness of the risk of PFAS contamination in water has strengthened the search for more effective and sustainable treatment solutions. Primary and polyfluoroalkyl substances (PFAs) pose major challenges in water treatment due to their association with persistence and adverse health effects. Although traditional removal techniques are widely used, they frequently require media replacements, are sensitive to organic matter and other contaminants, and exhibit limitations when dealing with short-chain PFAs. Weaver Labs’ Fluor-Mop technology provides selective, effective and cost-effective PFA removal. Fluor-Mop is specially designed to target PFAs, has best-in-class PFAS selectivity, and has up to 8 times better removal performance than conventional technology. Because Fluor-Mop is renewable on-site, it significantly reduces operating costs, reduces long-term cost of ownership, and makes it a more sustainable solution to the PFAS pollution crisis.

PFAS Challenge: Global Water Crisis

PFA is a synthetic chemical known for its water-resistant and grease-resistant properties and is widely used in consumer and industrial applications. However, these same properties make it extremely difficult to remove from the environment. PFA does not break naturally. They accumulate in water, soil, wildlife, and the human body. Today, PFA can be found in almost every human on Earth.

This is more than an environmental issue. That is a public health risk. PFAS exposure is associated with adverse health effects. Therefore, regulations such as PFA enforceable drinking water standards have been developed, and many water systems need to implement PFA removal. It is estimated that more than half of Americans have PFAS-contaminated drinking water that exceeds the EPA’s proposed limits. These numbers could be even higher in Europe, subject to regulations. However, current water infrastructure is not built with PFAS contamination in mind, and current removal techniques are not designed for PFA removal. The cost of repairs is extremely high, with estimates ranging from $200 billion in the US to over $100 billion in Europe annually. As PFA contamination continues to challenge water systems, traditional restoration techniques alone are not enough for comprehensive removal.

Weaver Labs Fluor-Mop: Redefining PFA Removal

Weaver Labs has designed a smarter, more effective solution. Fluor-Mop technology is a proprietary renewable PFA removal technology that is up to eight times better than traditional methods. Unlike traditional methods, Fluor-Mop is specially designed to target PFAs and approaches this at a molecular level. The result was a silica-based adsorbent designed to form multiple strong interactions with both long and short chain PFAS compounds, while not affected by other contaminants in the water.

Key Performance Highlights

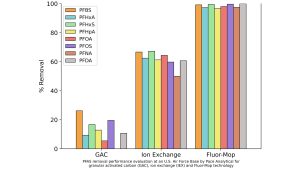

The performance of Fluor-Mop was verified with a real water matrix from PFAS contaminated sites using comparative studies and traditional removal methods.

Verified through challenging real-world testing: successfully tested with PFAS contaminated water from US Air Force Bases and confirmed removal performance by independent third-party performance ratings. High Removal Efficiency: Fluor-MOP demonstrated almost complete removal performance of eight different PFAS compounds, ranging from long-chain to short-chain PFAs. Outperformed traditional methods: Evaluation showed that Fluor-MOP consistently exceeded the removal performance of granular activated carbon (GAC) and ion exchange resin (IEX) across all tested compounds, with higher bars consistently exceeding that of better removal performance.

Reducing costs, greater impact

Fluor-Mop is less effective and more economical. Unlike other technologies, Fluor-Mop can be regenerated in multiple cycles, with very limited performance losses using standard industry processes. These regeneration processes can be tailored to a specific treatment system, ultimately allowing for convenient on-site regeneration.

This allows for some shocking solutions.

Cost Reduction: Operating costs are reduced by 50% and lifecycle costs are reduced by 35% over 20 years. Waste reduction: generates minimal, high concentration waste, significantly reducing the processing and destruction costs of subsequent repair procedures. Allows for full repair: Higher PFAS concentrations, optimized for PFAS destruction technology

Lack of interfering contaminants; achieve a more efficient and cost-effective overall treatment.

Together we solve the crisis

There is no single solution to the PFAS crisis. This is a complex and enduring challenge that calls for collaboration across industries, technology and regulators. Weaver Labs builds solutions that fit the scale and urgency of the problem. This is a powerful, practical and proven solution in the field. We believe that the most effective advancements are built on partnerships and innovation. Currently, leading technology providers across the water sector are evaluating the technology in their treatment systems, ensuring they can serve local governments and industrial end users more reliable and cost-effective.

Together with industry leaders and water treatment experts, we are building new standards for repairing PFA: smarter, faster, more sustainable. Combine expertise, resources and determination to tackle this important water challenge together.

This article will also be featured in the 23rd edition of Quarterly Publication.

Source link