The PFASER electrooxidation process, which includes a patented boron-doped diamond electrode, is set up to provide groundbreaking on-site processing of PFA with zero sludge, combined with a proprietary chlorate removal process.

The intrinsic chemistry of Per- and Polyfluoroalkyl substances (PFAs) makes them highly resistant to conventional treatments. As a result, these toxic molecules are ubiquitous as they can be found almost anywhere on Earth, including water, soil, and creatures. In response, governments around the world are pushing forward with new PFA regulations and guidelines, tightening thresholds, limiting non-essential use, and calling for greater accountability for long-term impacts.

For the majority of municipalities, utilities, airports, manufacturers and landfill operators, this evolving landscape poses two challenges.

Short Timetable: Design and deploy a proven, easy to operate, and cost-effective treatment system before penalties or liability arises. Life Accountability: PFA is captured and exported to external sites and ultimately treated at very high temperatures or pressures, supercritical hydroxylation (SCWO), plasma or hydrothermal alkaline treatment (HALT), indicating that PFA is permanently destroyed in the field.

PFASER, an advanced electrooxidation (EO) system developed by WSP, addresses these challenges with groundbreaking effectiveness, operational efficiency and flexibility. This article explores current therapeutic techniques, including key strengths and limitations, compares them with the key features of PFASER, and provides detailed technical and strategic perspectives for utilities, technology partners, policymakers and investors.

Why there is a shortage of current treatments

PFAS Separation Technology

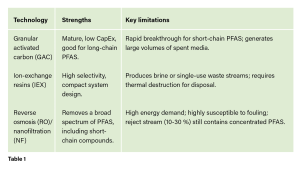

PFA presents a major challenge to water treatment professionals because of its persistence and resistance to traditional repair methods. Most full-scale PFAS solutions today rely on “separation” rather than “destruction.” Granular activated carbon (GAC), ion exchange (IEX) resins, reverse osmosis (RO), and nanofiltration (NF) are effective in removing PFA from water, but do not decompose molecules. As a result, these processes generate secondary waste streams and require further handling, often through incineration, landfill or regeneration. These downstream processes are associated with high operating costs and substantial carbon emissions.

Table 1 summarizes important PFAS separation techniques that remove PFA from water but do not destroy molecules.

As Dr Valerie Lebeyle, senior water treatment engineer at WSP in Canada, he said in a March 2025 webinar:

PFAS Destruction Technology

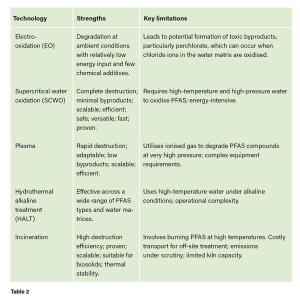

Given recent advances, technologies aimed at disrupting PFAs are increasingly considered favorable. Techniques such as EO represent important evolutions in therapeutic philosophy, focusing on the permanent removal of PFA rather than simply changing contamination to another medium. Nevertheless, the possibility of complete destruction is the ultimate goal, but these technologies present significant challenges, including the risk of secondary toxicity byproduct formation and substantial energy requirements, which may serve as limiting factors under specific operational or site-specific conditions.

Destructive techniques to decompose PFAS molecules at the chemical level provide a more permanent solution. However, most of these methods rely on high temperature processes, increasing energy requirements and carbon footprint, especially when carried out from the field. EO technology is the only technology that can decompose PFA in ambient conditions. The only important limitation is the formation of toxic byproducts, especially perchlorates. This can occur when chloride ions in the water matrix are oxidized.

Table 2 compares important limitations with treatment methods designed to destroy PFA molecules.

The future of PFAS treatment is to advance automated solutions in-site solutions that prioritize molecular destruction and minimize environmental impact.

PFASER: Innovation at the intersection of needs and technology

PFASER is a patent-pending system developed by WSP that utilizes EO in combination with a per-chlorine removal system to achieve high-efficiency PFA destruction in the field in a modular, containerized form without generating toxic byproducts.

The next point encapsulates the core functionality and technical innovations of PFASER.

Electric oxidation by BDD electrodes of Pro Aqua

PFASER incorporates only Pro Aqua’s patented boron-doped diamond (BDD) electrode reactors, effectively eliminating more than 95% of the total PFA in contaminated water streams within minutes. BDD generates a direct electron transfer pathway with highly oxidative hydroxyl radicals that cleave the ultrastable C–F bond without chemical additives and without sludge generation. Unlike mixed metal oxidation anodes, BDD exhibits negligible wear and excellent stability. Commercially available cells have been operating for over 6 years without loss of performance.

Perchlorate Control

PFASER’s proprietary two-stage process – designed to target target GAC polishing followed by acidic hydrogen peroxide removal, resulting in a validated destruction rate of 99.999%, or less than 50 µg L-¹, maintaining GAC change out interval > 40 days > 40 days. This is especially important in waters with chloride.

Zero Sludge and Self Cleaning

Unlike traditional methods such as GAC and IEX, which concentrate PFA on used media that require expensive management or incineration, PFASER does not generate sludge. This eliminates the need for offsite transport and secondary waste disposal, and directly reduces operational costs and environmental liability. Additionally, self-purified reverse polarity features prevent mineral scaling.

Minimum chemical input

PFASER’s advanced EO process is designed to use very small amounts of supplementary chemicals, streamline therapeutic logistics and minimize the risk of dangerous by-product formation and chemical runoff into the environment. This promotes easy regulatory compliance and safety management in the treatment field.

Low energy, ambient operation

The system operates at ambient temperature and pressure and relies on standard power. There is no need to significantly reduce high-temperature reactors, pressure vessels, or complex heat management, capital costs and increase operational safety.

Rapid modular deployment and automation

Standard 20-foot containerized PFASER skids process up to day 1, up to 10m³. For industrial throughput, multiple skids are run in parallel. This plug-and-play format allows for rapid mobilization across a variety of industries and regions, in addition to supporting field trials, emergency responses and permanent installations. Remote SCADA enables 24/7 operation. This is essential for remote repair wells and airport break-off pads.

Speaking at the WSP webinar, Dr. Léveille said: “In a residence time of 30-60 minutes, we achieved up to 95% PFAS mass destruction, including stubborn C8 species such as PFOA and PFOS.

Pilot Results and Early Applications

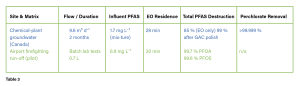

Bench-scale and real-world testing confirms that PFASER lab performance is converted into a field. Two representative cases (Table 3) show how the same boron-doped-doped-doped-domond EO core, adjusted only for flow and hydrogen peroxide dose, provides consistent removal in very different water matrices. (Reported as σ‑ PFAS unless otherwise stated.)

In fact, PFASER cuts 70-99% of total PFA in 28-60 minutes (less than 25 mA cm-²) without generating sludge or spent medium. The small GAC polish is done upstream by EO, so it lasts for several months. Tests on airport runoffs that contain chloride-rich groundwater and membrane-forming bubbles (afff) ensure that a single standardized EO core can handle highly different feeds. The deployment ranges from a 20-foot mobile skid roaming a plume of chemical plants to a compact “PFAS pit stop” in the airport drainage. These pilot efforts pave the way for ongoing full-scale builds (groundwater at 4m³D-¹ airport and 30m³D-¹ microelectronics wastewater), with commissioning already looking at ongoing and early indicators.

Rapid on-site PFAS detection: Partnership with Fredsense

Real-time process control is important to minimize energy per kilogram of destroyed PFA. Through collaboration with Calgary-based Fredsense, the WSP Integrated Fred‑PFAS™ Biosensor Kit took part in pilot workflows and routine investigations. Handheld devices reduce total PFAS measurements to 1 µg L-¹ in less than 4 hours for standard LC‑ MS/MS lab analysis in 7-14 days.

Dr. Léveilé said: “By combining Fred‑ PFastm screening with PFASER data, we reduced pilot research time by 80%. Dynamic feedback dials residence time from 60 to 28 minutes without sacrificing removal targets.”

Looking ahead, globally scale PFA destruction

As regulations become more stringent and client demand accelerates, PFASER is already expanding to larger systems and wider applications.

Airport AFFF Impacted Groundwater: A comprehensive 4m³D-¹ treatment system is designed for Canadian airports with the aim of intercepting groundwater affected by AFFF operations. Perchlorate mitigation is not included as it is not explicitly regulated at the airport in relation to PFA repair. Microelectronic Wastewater: 30m³D-¹ Variant is a detailed design of a high mission facility and is tailored to destroy high-chemical oxygen demand process water (over 30,000 ppm). Cost Breakthrough: The mass production of Pro Aqua’s BDD electrodes will significantly reduce unit costs within a few years, making EO accessible to virtually any client. Regulation Preparation: With zero secondary waste, PFASER is aligned with US PFA disposal guidance and anticipates the EU’s best approach for zero contamination standards.

Conclusion and a call to action

PFASER stands as a benchmark for advanced water treatment. It’s a practical and scalable option as it shows that destruction in sources is no longer ambitious.

Eliminate up to 95% total PFA and 99.999% perchlorate in a few minutes. Generates sludge zero, zero off-site transport, and minimum chemical inputs. It uses low energy output and does not have high temperature or high pressure to break the PFA. Fits standard containers for rapid deployment across the industry.

WSP invites you to accelerate a future without PFAS.

Utilities and site owners who pilot PFASERs in challenging waters. A technology partner that integrates EO with upstream separation or downstream polishing. Investors and policymakers supporting the implementation of PFASER and manufacturing field units.

“PFAS Destruction is a team sport. By integrating detection, advanced oxidation and smart engineering, we can turn regulatory pressures into cleaner and safer water opportunities around the world,” added Dr. Léveille.

Technology is here. There are results. The next steps are collaboration and urgency.

This article will also be featured in the 23rd edition of Quarterly Publication.

Source link