Solventless, PFAS-free LCO, LFP, NMC electrodes increase performance, accelerate cleaner and accelerate drop-in production.

Ateios Systems is redesigning how lithium-ion batteries are creating with a focus on clean production, higher performance and faster scale-up. Our core platform, Raicure™, uses solvent-focused, Forever Chemical (PFAS)-dependent treatments to increase energy density, reduce costs, reduce emissions, maintain compatibility with existing roll-to-roll devices, enable customers to adopt at their own pace, and reduce emissions. Our process offers an independent assurance that Intertek is the only third-party certified PFAS-free in the world, and eliminates fluorinated binders from the electrode manufacturing step. A NYU study found that PFA is sold for $20/kg, but the actual social costs are over $20,000/kg. Regardless of the evolution of regulations, PFAS-based supply chains continue to face significant risks and rising costs as they become increasingly difficult to generate in compliance with increased regulations and potential litigation.

Raicore Solutions

Built on this platform, the RAICORE™ product line supplies ready-to-integrate electrodes for chemical device manufacturers and battery OEMs. In other words, today’s high voltage lithium cobalt oxidation phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate phosphate These benefits support slimmer products, longer disability, and faster routes to qualifications.

Benefits of our approach

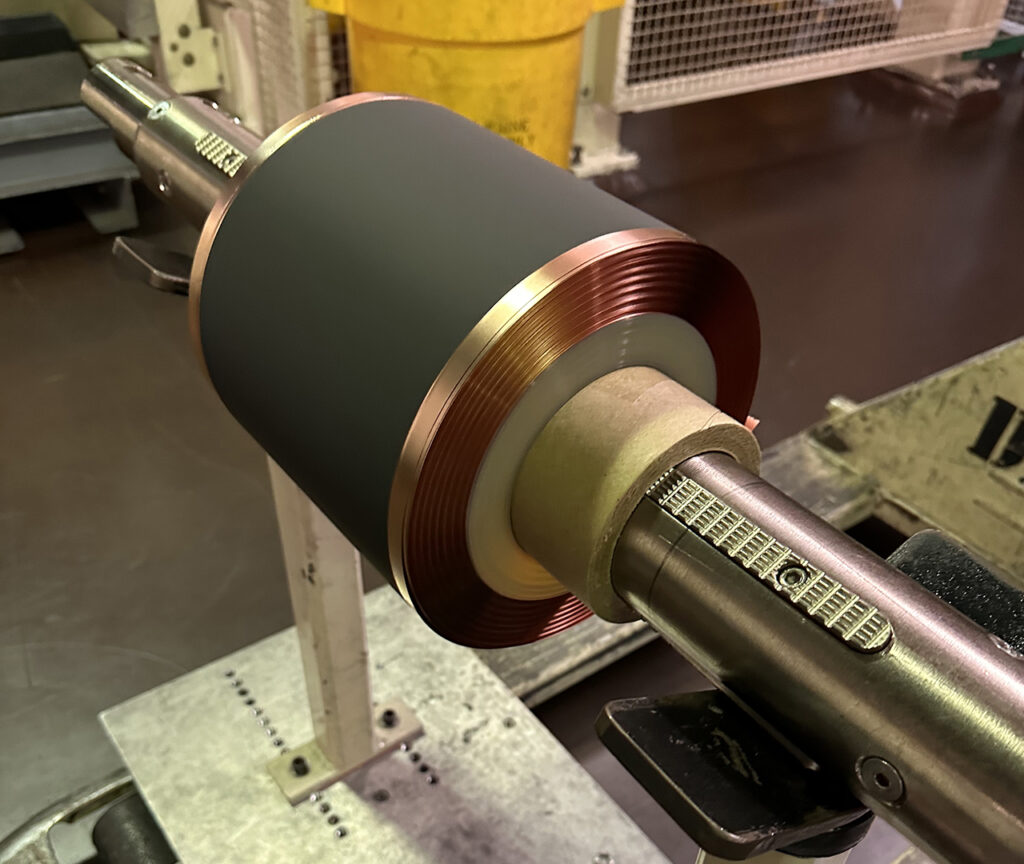

Our manufacturing approach is intentionally harmful. Rather than building a Greenfield factory, we leverage established toll plaza manufacturing and assembly partners to scale our output quickly and responsibly. This model provides customers with immediate access to pilots and production capacity, compressing the timeline from samples to commercial orders. At the toll partner facility, electrode execution was completed and assembled into production grade cells for customer qualification at GWH production rate.

The benefits of speed and cost are built into Raicure. By curing with energy rather than long heat ovens or solvent recovery trains, our process architecture reduces energy usage and operating footprint by almost 90%, and our high-throughput coatings are almost 10 times higher. This process has been verified at coating speeds of up to 50m per minute and is already integrated into production lines around the world. These improvements flow directly into better line economics and higher capacity per installed coater. Raicure is designed to interface with standard roll-to-roll equipment, allowing profits to arrive without imposing changes to the wholesale factory.

Promote customer success

Commercially, it focuses on measurable customer outcomes. Since the launch of the Raicore HV LCO, we have shipped sample packs to accelerate A/B testing, supported pay pilots with multiple battery assemblers to integrate Raicore into existing cell formats, and protected partner capacity measured at hundreds of megawatt hours a year to support recent demand. For teams who prefer turnkey results, our partner network can also provide a complete cell built with Raicore electrodes, providing a clean and practical path to the market.

Utilizing public funds

Public funding and third party verification support our scale-up. Ateios has secured $350,000 in support of the National Science Foundation’s “engine” through Binghamton University’s New York Energy Storage Engine. This includes the $150,000 R&D award and the $200,000 Super Boost award, which funds Kilometer-scale campaigns and customer qualifications. The NSF program, led by Binghamton, focuses on building household battery hubs, including component manufacturing, sustainable cell production, material recovery, pilot manufacturing, safety testing, integration, and workforce development. This is directly in line with customer priorities regarding performance, compliance and resilient supply.

Streamlined integration and increased efficiency

Recruiting is easy for engineering teams. Starting with ready-made Raicore electrodes, benchmark benchmark performance, proceed to pilots on existing lines and scale through paid manufacturing partners or qualified suppliers. Raicore is a drop-in solution, so procurement can do dual sources during transitions, quality can track standard metrics, and operations can unlock higher yields and fewer bottlenecks as solvent and PFA steps are removed. Our platform page provides an overview of available chemistry and sampling options, making it easy to match your material invoice and validation plan.

Improved sustainability and safety in electrode production

Environmental rationales are equally strong. Traditional PVDF and NMP-based routes require long drying ovens, VOC reductions, and large dry room infrastructure. By removing solvents and PFA from the electrode process, raicure reduces energy consumption and operational complexity and improves safety. This architecture supports regulatory and brand goals by removing “eternal chemicals” from the process, reducing factory energy use and overall environmental impact. Intertek Certification offers additional warranty for compliance teams and brand stewards seeking verification, fluorine-free manufacturing.

Innovative and practical options

Ateios serves consumers and markets where performance, safety and supply guarantees intersect, including medical wearables, IoT devices, tools, drones, AR or VR. In these categories, energy density and cycle life are important, which is why high voltage LCOs are popular, and why certified PFA-free options are valuable. With Raicore, you can choose the best chemistry for your product roadmap, including the largest runtime HV LCO, cost-safe LFP, and NMC for energy and power balance, maintaining a consistent and clean manufacturing foundation.

Our mission is to help the industry get fewer batteries while still doing it responsibly. By integrating higher performance, solvent-free, certified PFA-free manufacturing, high-throughput scalability, and Fabless models tapping world-class toll and assembly partners, Ateios offers a practical route to clean energy stores at scale. If your team is ready to evaluate, you can quickly validate and move into production with confidence as they send samples, share data, and set up a pilot with a line or qualified partner.

This article will also be featured in the 23rd edition of Quarterly Publication.

Source link