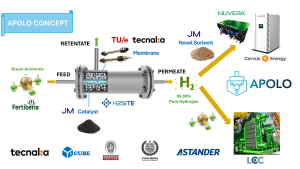

The APOLO project, coordinated by Tecnalia and technology leader H2SITE, aims to fully decarbonize the maritime sector using membrane technology for ammonia splitting.

The APOLO project (Advanced Power Conversion Technology Based on Shipboard Ammonia Decomposition with Advanced Membrane Reactors) focuses on power conversion for shipboard applications by enabling the use of ammonia as a clean alternative fuel for marine applications. APOLO’s mission is to develop advanced and flexible ammonia cracking technologies that can be integrated with fuel cells (FC) and internal combustion engines.

Development of two demonstration prototypes

The consortium will focus on exhibiting the following demonstration units (prototypes):

The 125kW power conversion system combines an ammonia cracker (H2SITE) and proton exchange membrane (PEM) fuel cell (Corvus Energy Fuel Cells and Nuvera, tested separately at different inlet pressures) systems, achieving an overall system efficiency of 51% to 54%. The ammonia cracker is customized to operate at different pressure conditions and efficiency levels to evaluate the flexibility of the cracker system for all types of PEM fuel cells. It combines a 125kW partial ammonia cracker (H2SITE) and a 4-stroke engine (LEC) with an overall system efficiency of over 45%. A selective catalytic reduction (SCR) system will also be developed to remove nitrogen oxide (NOX) emissions from the new engine’s exhaust.

Overall, APOLO has the ambition to design and test new modular, easily scalable and flexible fuel delivery systems, including new compact membrane reactors that can be used interchangeably with internal combustion engines and fuel cells. This membrane reactor enables the provision of a fuel mixture suitable for use in heat engines or a pure fuel cell grade hydrogen stream to feed PEM fuel cells. This innovative fuel delivery system will be integrated into a complete power conversion system and optimization work will be carried out using both modeling and experimental work to find the most suitable vessel configuration. For the first time, APOLO builds, validates, and compares two different power conversion technologies with an overall process efficiency of 45% to 51%.

The technology developed at APOLO can target the first 30,000 ships on the market. Initially, the focus will be on vessels with propulsion between 1 and 10 MW, but over the next decade many will be around 3 MW, as these vessels are the first to be associated with ammonia-powered solutions.

Ammonia decomposition by membrane reactor (CMR)

The core of APOLO technology is the decomposition of ammonia, also known as cracking. This process converts ammonia (NH3) to nitrogen (N2) and hydrogen (H2) to nitrogen (N) and hydrogen (H) (2NH3 ↔ 3H2 + N2, ΔH = 46 kJ mol-1). This is the reverse reaction of the Haber-Bosch method for synthesizing ammonia. Therefore, ammonia cracking is a means of hydrogen production, and this hydrogen can be used as an alternative to traditional fossil fuels. This reaction is endothermic and is accelerated at low pressure and high temperature.

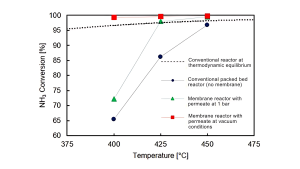

The most common industrial scale ammonia cracking systems offer electrically based furnace solutions with packed bed reactors. This reactor produces forming gas (a mixture of H2 and N2) and operates at very high temperatures, typically 800-900 °C. Significant efforts are being made to improve this technology by integrating solutions such as the use of alternative catalysts to lower operating temperatures, additional cleanup systems to remove unreacted ammonia (<30 ppm) and N2 (up to 25%), and ammonia recovery units for systems (such as PEM fuel cells) that require high-grade pure hydrogen (ISO 14687:2019).

Packed bed catalytic membrane reactors (CMRs) offer a simpler solution to this problem. Integrating hydrogen separation membranes into conventional reactors allows complete conversion of ammonia at lower operating temperatures (400-450°C), avoiding thermodynamic equilibrium limitations.¹ In this case, as soon as ammonia is decomposed into H2 and N2 with the help of a catalyst, the membrane selectively separates H2. APOLO uses palladium (Pd) membranes for this purpose, with an ideal H2/N2 permselectivity of >100,000 at 425°C. This ensures high H2 separation efficiency at lower operating temperatures compared to conventional systems, which is beneficial from an energy perspective. The released hydrogen can be directly fed to the fuel cell after a very simple polishing process using an adsorbent to remove excess ammonia to avoid damage to the FC. The physical footprint is also significantly reduced as the entire process takes place in a single unit, which is beneficial for ships.

H2SITE, together with Tecnalia and Eindhoven University of Technology (TU/e), has already demonstrated the advantages of CMR compared to state-of-the-art cracking technologies through the EU-funded project ARENHA. Further optimization of the Pd membrane will be carried out by these partners through the APOLO project. Johnson Matthey will research innovative and environmentally friendly catalysts for ammonia cracking and new adsorbents for hydrogen polishing for fuel cells.

fuel cell

PEM FC is gaining interest as a potential power source for both propulsion and auxiliary power for ships. One of the key advantages is high efficiency, which can exceed that of traditional internal combustion engines. They also have lower noise levels, making them a more comfortable option for passengers and crew. Additionally, because it does not require combustion, it does not produce greenhouse gases (GHGs) or other harmful emissions. Ammonia cracking produces forming gas with still high nitrogen and ammonia content for FC, so the challenge remains to achieve hydrogen purity suitable for PEM fuel operations. This can reduce fuel cell performance and possibly cause premature fuel cell degradation. To that end, ISO 14687:2019 pure hydrogen produced by an ammonia cracker followed by an adsorbent polishing step can be used as feed to the PEM to decarbonize transport. Corvus Energy Fuel Cells and Nuvera (Hyster Yale SpA) will conduct fuel cell testing at both low pressure conditions from the cracker and high inlet pressure conditions.

ammonia engine

The power conversion system of an ammonia ship operating with an internal combustion engine consists of two main parts: propulsion and auxiliary equipment. The engine itself is a critical component of the power conversion system and must be designed to operate on ammonia fuel. Ammonia does not contain carbon, so it does not emit CO2 when burned. Nevertheless, NH3 is a difficult fuel to ignite when used for engine combustion. Due to the high ignition energy requirement, a pilot fuel or “hot” source is required for proper ignition. Fuel supply systems containing crackers for the production of NH3/H2 mixtures are particularly promising during cold starts. Additionally, hot flue gas from the engine exhaust can be used to supply heat to the cracking reactor to optimize heat integration between the cracking and combustion steps. SCRs based on copper (Cu), iron (Fe), and vanadium (V) will also be developed to remove NOx emissions from the exhaust of new engines. The Large Engine Competence Center (LEC) is leading research into these ammonia combustion engines, with Johnson Matthey working on SCR catalysts.

Comprehensive consortium

Additionally, APOLO leverages the expertise of Fertiberia (green ammonia provider), Astander (shipbuilder), and 1CUBE (dissemination organization) for the complete implementation, transfer, and exploitation of its technology. During APOLO, a techno-economic analysis and life cycle assessment will be carried out by Chalmers University, as well as a health, safety and environmental assessment inspired by the HAZOP/HAZID protocol by Tecnalia and Fertiberia. APOLO, through Bureau Veritas, also aims to propose amendments to EU and IMO regulations on the use of ammonia as fuel/power conversion systems in the maritime sector.

Currently, APOLO at M21 is progressing on schedule with the development of key components for membrane reactors (membranes, catalysts, adsorbents), fuel cells, and ammonia engines. During this period, a market analysis with preliminary exploitation strategies is also carried out. APOLO is therefore ready to support the maritime sector in achieving the decarbonization targets set by FuelEU Maritime, Fitfor55 and the European Green Deal regulations.

Acknowledgment

Funded by the European Union under grant agreement number 101138466. However, the views and opinions expressed are those of the authors alone and do not necessarily reflect those of the European Union or the European Climate Infrastructure and Environmental Enforcement Agency (CINEA). Neither the European Union nor CINEA can be held responsible for them.

References

Gallucci et al., Fuel Processing Technology, 2021, 216, 106772

This article will also be published in the quarterly magazine issue 24.

Source link