Cold plasma technology is revolutionising textile manufacturing, offering sustainable surface modifications that traditional chemical processes cannot achieve.

The textile industry faces an urgent sustainability crisis. Traditional finishing processes consume vast quantities of water, use hazardous chemicals, and require energy-intensive operations that contribute significantly to industrial pollution. As environmental regulations tighten and consumer awareness grows, the need for cleaner, more efficient textile processing technologies has never been more critical. At the forefront of addressing this challenge, researchers at the Università degli Studi di Milano-Bicocca (UNIMIB) have spent over two decades developing and refining cold plasma technology as a transformative solution for textile surface modification.¹

Led by Professor Claudia Riccardi and her group at the Dipartimento di Fisica ‘G. Occhialini’, this research group has systematically investigated how plasma – the fourth state of matter – can fundamentally alter textile surfaces at the nanometre scale without affecting their bulk properties. Their work, conducted in collaboration with colleagues from the Università degli Studi di Milano, Stazione Sperimentale per la Seta, and industrial partners, represents a comprehensive approach to understanding plasma-textile interactions and translating fundamental research into practical applications.²

(Image is generated using AI Perplexity Claude 4.0 Sonet Thinking)

Pioneering plasma reactor design and diagnostics

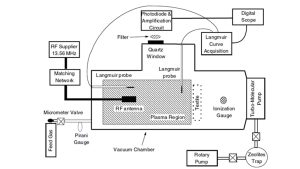

A cornerstone of the Milano-Bicocca group’s success has been its development of specialised plasma reactor systems specifically designed for textile treatment. The team designed and constructed a T-shaped cylindrical radiofrequency (RF) plasma reactor – a 10 cm diameter, 27 cm long chamber — driven by a capacitive RF antenna operating at 13.56 MHz. This configuration allows precise control over plasma parameters and uniform treatment of textile specimens positioned at various distances from the antenna.³

What distinguishes their approach is the emphasis on comprehensive plasma diagnostics. Rather than treating plasma as a ‘black box’, Professor Claudia Riccardi and her group implemented sophisticated diagnostic systems using movable electrostatic probes to measure local plasma properties. Their measurements revealed that the reactor produces a diffuse plasma region extending approximately 10 cm around the RF antenna, with electron densities ranging from 10⁷ to 10⁹ cm–³, ion densities between 10¹⁰ and 10¹² cm–³, and electron temperatures of 5-10 eV. These measurements demonstrated that in electronegative gases like air, ion density dominates over electron density by at least two orders of magnitude, making ion bombardment a critical factor in plasma-textile interactions.1,3

The group also employed optical emission spectroscopy to analyse the chemical composition of the plasma discharge during treatment. By identifying emission lines from specific species – such as fluorine atoms at 703.7, 685.6, and 712.8 nm in SF₆ plasma, or atomic nitrogen and oxygen in air plasma – they could correlate plasma composition with observed surface modifications. This diagnostic capability enabled them to optimise treatment conditions based on understanding the underlying physics and chemistry, rather than through trial and error alone.³

Transforming polyester dyeability through air plasma

One of the most significant achievements of the Milano-Bicocca team was demonstrating that appropriate air plasma pretreatment could dramatically improve the dyeability of polyethylene terephthalate (PET) fibres – the most widely used synthetic textile. Conventional PET dyeing requires temperatures exceeding 100°C, substantial water consumption, and auxiliary chemicals – a resource-intensive process with significant environmental impact. Through systematic investigation of plasma parameters including RF power (50-200 W), gas pressure (0.05-1.0 mbar), treatment time (1-10 minutes), and sample position relative to the antenna, the researchers identified optimal conditions that increased colour depth by 50-100% compared to untreated fabrics. The percentage increase in the Kubelka-Munk coefficient (K/S), which quantifies dye uptake, reached values exceeding 100% for samples treated under specific conditions.1,2

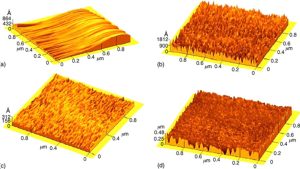

Their investigations revealed that this enhancement stemmed from multiple synergistic effects. As shown in Fig. 2, using atomic force microscopy (AFM), the team documented how plasma treatment created surface roughness through controlled etching. The root-mean-square (RMS) roughness increased from approximately 19 nm for untreated PET to over 40 nm after optimal air plasma treatment. This microscopic surface texturing physically trapped dye molecules and reduced light reflection, intensifying perceived colour. Importantly, their AFM studies confirmed that the topographical modifications persisted through the dyeing process, maintaining their contribution to enhanced colour depth.⁴

X-ray photoelectron spectroscopy (XPS) analysis conducted by the research group revealed significant chemical modifications accompanying the physical changes. Air plasma treatment introduced both oxygen and nitrogen-containing polar groups on the PET surface, with O/C atomic ratios increasing from 0.27 for untreated PET to 0.3 – 0.5 depending on treatment conditions. Deconvolution of C1s XPS spectra showed increased peaks attributable to C-O and C-N bonds, indicating introduction of hydroxyl, carboxyl, and amine functionalities that improved the affinity between hydrophobic fibres and dye molecules.1,2

Critically, the UNIMIB group demonstrated that the dyeability enhancement was not a kinetic effect – the apparent diffusion coefficient of dye within fibres remained unchanged after plasma treatment. Instead, the saturation dye uptake increased, confirming that plasma modification provided more sites for dye binding rather than simply accelerating dye penetration. This distinction has important implications for industrial implementation, as it means shorter treatment times can achieve superior results compared to conventional methods.

Engineering hydrophobic surfaces with fluorinated plasmas³

In parallel with their work on hydrophilic modifications, the research team investigated how plasma treatment could impart extreme water repellency to textiles – a property essential for outdoor applications, protective clothing, and technical textiles. Their systematic study of sulfur hexafluoride (SF₆) plasma treatment revealed a remarkable pressure-dependent transition in surface properties. The discussed work, the reactor, is shown in Fig. 3.

At SF₆ pressures below approximately 0.2 mbar, plasma treatment increased PET hydrophilicity, with water droplet absorption times decreasing from 180 seconds for untreated fabric to just a few seconds. However, at pressures exceeding 0.2 mbar, a striking reversal occurred: treated fabrics became superhydrophobic, with water droplets evaporating from the surface before being absorbed (absorption time >3600 seconds). This sharp transition occurred within a narrow pressure range of 0.17 – 0.22 mbar. Through their comprehensive diagnostic approach, their group explained this phenomenon by correlating optical emission spectra with surface characterisation. At low pressures, the higher ionisation degree and longer mean free path of electrons and ions resulted in more efficient bombardment of the fibre surface, causing etching and surface activation. At higher pressures, fluorine atom density in the plasma increased dramatically – as evidenced by stronger fluorine emission lines – while ion bombardment efficiency decreased, allowing direct fluorine grafting onto polymer chains to predominate.⁵

XPS analysis confirmed this interpretation, showing F/C atomic ratios ranging from 0.012 at 0.05 mbar (with modest hydrophilicity increase) to 0.52 at 0.40 mbar (with excellent water repellency). The direct correlation between surface fluorine content and hydrophobicity validated their understanding of the underlying mechanisms. Notably, samples treated under optimal hydrophobic conditions also exhibited increased dyeability by approximately 5%, demonstrating that surface roughness from etching contributed to colour enhancement even when chemical modifications promoted hydrophobicity.⁶

HMDSO plasma for multifunctional coatings

Recognising that fluorinated treatments might not be suitable for all applications, the UNIMIB group, led by Professor Claudia, investigated hexamethyldisiloxane (HMDSO) plasma as an alternative route to hydrophobic surfaces. HMDSO, an organosilicon monomer, can be plasma-polymerised to deposit thin silicone-based coatings with properties tunable through deposition parameters.⁷

Our work demonstrated that HMDSO plasma treatment of paper and lignocellulosic materials could impart excellent water repellency, with water droplets remaining on treated surfaces for over an hour and, in some cases, evaporating before absorption. Fourier-transform infrared (FTIR) spectroscopy revealed that the deposited films retained characteristic absorption bands for methyl groups (Si-CH₃ at 1260 cm-¹, CH₃ rocking in Si-CH₃₂ at 800 cm-¹, and Si-CH₃ rocking in Si-CH₃₃ at 840 cm-¹), which are essential for hydrophobic properties. The research showed that hydrophobicity depended critically on monomer structure retention during plasma polymerisation. By operating at relatively high HMDSO pressures (≥0.1 mbar) and moderate RF power, the group achieved coatings with high methyl group content and optimal water repellency. Lower pressures or excessive power input caused more extensive fragmentation of the monomer, producing more SiO₂-like films with reduced hydrophobicity.⁸

An important finding from the group’s investigations was that HMDSO-treated samples exhibited no aging effects – the hydrophobicity remained stable over time. This contrasted with SF₆-treated samples, which showed partial recovery of hydrophilicity after several days of atmospheric exposure. The superior durability of HMDSO coatings stemmed from their nature as deposited layers rather than grafted surface species, making them less susceptible to surface reorganisation phenomena8,9

Extending plasma technology to natural fibres10

While much of their work focused on synthetic polymers, the Milano-Bicocca group also investigated plasma treatment of natural and lignocellulosic materials. Zanini’s doctoral research specifically addressed plasma treatments of lignocellulosic fibres, paper, and wood. These materials present unique challenges due to their complex hierarchical structure, hygroscopic nature, and chemical heterogeneity. For CTMP (chemi-thermomechanical pulp) fibres, the research demonstrated that argon plasma treatment promoted the formation of phenoxy radicals on the fibre surface. These activated sites could then react with acrylic acid vapours to graft carboxylic functionality, increasing the carboxylic group concentration by 20.5%. Alternatively, direct plasma polymerisation of acrylic acid in the presence of argon carrier gas achieved even higher functionalisation, with carboxylic group concentrations increasing by 33.6%.

The group’s work on paper emphasised the dual nature of plasma effects – both surface chemistry modification and topographical changes. SF₆ plasma treatment at appropriate pressures imparted excellent water and oil repellency to paper, with contact angles comparable to those of polytetrafluoroethylene. However, they also observed that treatment parameters needed careful optimisation to balance fluorine grafting against excessive etching that could compromise paper mechanical integrity.

From laboratory to application: Bridging the gap11

Throughout their research programme, they maintained awareness of the practical requirements for industrial implementation. Their reactor designs considered scalability issues, and they investigated continuous treatment possibilities by positioning samples at various locations within the plasma. The group’s emphasis on understanding aging phenomena – how plasma-treated surfaces evolve when exposed to the atmosphere or immersed in water – addressed crucial durability questions for commercial applications.

Their work also documented some of the challenges that must be overcome. Plasma treatment parameters are highly interdependent: small variations in pressure, gas composition, RF power, or treatment time can dramatically alter results. The textile substrates themselves introduce variability – residual finishes, moisture content, and fabric structure all influence plasma-surface interactions. Moreover, they observed that iron contamination from antenna sputtering could occur under certain high-power conditions, necessitating careful parameter selection or equipment design modifications.

Despite these challenges, the body of work produced by the UNIMIB plasma group over more than two decades provides both fundamental understanding and practical guidance for implementing plasma technology in textile finishing. Their systematic approach – combining reactor development, comprehensive diagnostics, surface characterisation by multiple techniques (XPS, AFM, optical emission spectroscopy, contact angle measurements, dyeability testing), and correlation of plasma parameters with observed effects – has created a knowledge base that enables rational optimisation of plasma processes for specific textile applications.

Looking forward

The research conducted by Professor Claudia Riccardi and her group at UNIMIB, with their collaborators, demonstrates that cold plasma technology offers genuine solutions to pressing challenges in textile manufacturing. Their work has shown that appropriate plasma treatment can reduce dye consumption by achieving superior colour depth, eliminate chlorine from wool shrinkproofing, replace water-intensive hydrophilic treatments, and create durable functional coatings – all through dry, environmentally friendly processes operating at room temperature.

As the textile industry continues its necessary transition toward sustainability, the foundational understanding and practical insights generated by this research group position plasma technology as an essential tool for next-generation textile finishing. The path from laboratory to large-scale implementation requires continued investment in process development and equipment optimisation, but the Milano-Bicocca team’s comprehensive body of work provides both the scientific foundation and the practical guidance needed to make that transition successful.

Acknowledgements

This work would not have been possible without the contributions of graduate and undergraduate students and Postdocs working in the lab, especially Dr Ajinkya Trimukhe, who pioneered in writing this article. I want to thank all former and current lab members for their hard work and dedication. I would like to acknowledge the PlasmaPromteo group of UNIMIB, the MUSA – Multilayered Urban Sustainability Action, and the funding by the National Plan for NRRP Complementary Investments (PNC, established with the decree-law 6 May 2021, n. 59, converted by law n. 101 of 2021) in the call for the funding of research initiatives for technologies and innovative trajectories in the health and care sectors (Directorial Decree n. 931 of 6 June 2022)—project no. PNC0000003— AdvaNced Technology for Human centEred Medicine (project acronym: ANTHEM). This work reflects only the authors’ views and opinions; neither the Ministry for University and Research nor the European Commission can be considered responsible for them.

References

Riccardi C, Barni R, Selli E, et al. Surface modification of poly(ethylene terephthalate) fibers induced by radio frequency air plasma treatment. Appl Surf Sci. 2003;211(1-4):386-397. doi:10.1016/S0169-4332(03)00265-4

Raffaele-Addamo A, Selli E, Barni R, et al. Cold plasma-induced modification of the dyeing properties of poly(ethylene terephthalate) fibers. Appl Surf Sci. 2006;252(6):2265-2275. doi:10.1016/J.APSUSC.2005.04.013

Barni R, Riccardi C, Selli E, et al. Wettability and Dyeability Modulation of Poly(ethylene terephthalate) Fibers through Cold SF6 Plasma Treatment. Plasma Process Polym. 2005;2(1):64-72. doi:10.1002/PPAP.200400054

Poletti G, Orsini F, Riccardi C, Raffaele-Addamo A, Barni R. Atomic force microscopy investigation of cold-plasma-treated poly(ethyleneterephthalate) textiles. Surf Interface Anal. 2003;35(4):410-412. doi:10.1002/SIA.1543

Selli E, Mazzone G, Oliva C, et al. Characterisation of poly(ethylene terephthalate) and cotton fibres after cold SF6 plasma treatment. J Mater Chem. 2001;11(8):1985-1991. doi:10.1039/B101360M

Riccardi C, Barni R, Fontanesi M, et al. A SF6 RF plasma reactor for research on textile treatment. Plasma Sources Sci Technol. 2001;10(1):92. doi:10.1088/0963-0252/10/1/312

Barni R, Zanini S, Riccardi C. Characterization of the Chemical Kinetics in an O2/HMDSO RF Plasma for Material Processing. Adv Phys Chem. 2012;2012(1):205380. doi:10.1155/2012/205380

Grimoldi E, Zanini S, Siliprandi RA, Riccardi C. AFM and contact angle investigation of growth and structure of pp-HMDSO thin films. Eur Phys J D 2009 542. 2009;54(2):165-172. doi:10.1140/EPJD/E2009-00117-6

Zanini S, Riccardi C, Orlandi M, et al. Surface properties of HMDSO plasma treated polyethylene terephthalate. Surf Coatings Technol. 2005;200(1-4):953-957. doi:10.1016/J.SURFCOAT.2005.01.093

Zanini S, Riccardi C, Canevali C, Orlandi M, Zoia L, Tolppa EL. Modifications of lignocellulosic fibers by Ar plasma treatments in comparison with biological treatments. Surf Coatings Technol. 2005;200(1-4):556-560. doi:10.1016/J.SURFCOAT.2005.01.090

Marcandalli B, Riccardi C. Plasma treatments of fibres and textiles. Plasma Technol Text A Vol Woodhead Publ Ser Text. Published online January 1, 2007:282-300. doi:10.1533/9781845692575.2.282

Please note, this article will also appear in the 24th edition of our quarterly publication.

Source link