Helium plays an important role in semiconductor manufacturing, affecting both the quality and efficiency of chip production.

Its unique properties, such as chemical inertness and low thermal conductivity, contribute to maintaining optimal manufacturing conditions. However, the industry faces significant helium supply challenges.

This situation raises important questions about the future of semiconductor technology and its potential impact on innovation and competitiveness. What strategies will the industry adopt to address these pressing concerns?

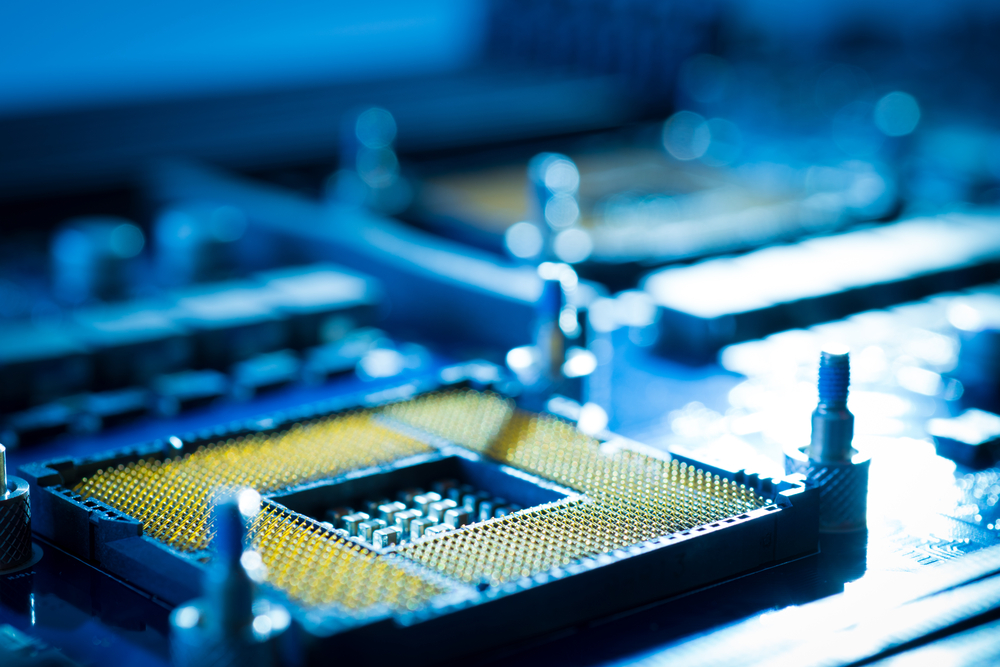

A key element in chip manufacturing: Why helium matters

Although often overlooked, helium plays a critical role in semiconductor manufacturing, especially the complex process of chip manufacturing. This noble gas is essential for maintaining optimal conditions during the various stages of production.

In the lithography process, helium is used to create a stable vacuum environment, ensuring precise alignment and exposure of the photomask. In addition, helium helps cool semiconductor materials, reducing thermal stresses that can affect chip integrity.

Its low density and inert nature make it an ideal carrier gas to transport materials without contamination. Additionally, helium’s ability to prevent oxidation during the etching process improves the overall quality and performance of semiconductor devices.

Therefore, helium is an essential element for achieving high-yield and reliable chip manufacturing.

Unique properties of helium and their impact on manufacturing accuracy

Helium’s unique properties greatly improve manufacturing accuracy in semiconductor manufacturing.

As a noble gas, helium is chemically inert, minimizing the risk of contamination during the manufacturing process. The low thermal conductivity allows precise temperature control, which is important for maintaining optimal conditions during chip manufacturing.

Additionally, helium’s light weight and small atomic size make it easy to use to create the ultra-clean environments essential for the sensitive processes involved in semiconductor manufacturing. This unique combination of properties allows manufacturers to achieve tighter tolerances and greater accuracy in circuit designs.

Additionally, helium’s ability to quickly diffuse through materials increases the effectiveness of various technologies, thereby supporting advances in semiconductor technology overall.

Taken together, these factors highlight the essential role helium plays in achieving high manufacturing precision.

Cooling, purging and plasma control

When it comes to semiconductor manufacturing, helium plays an important role in cooling, purging, and plasma control processes. The low boiling point allows efficient cooling of equipment and prevents overheating during complex manufacturing steps.

Helium’s inert nature means it will not react with chemicals used in manufacturing, making it an ideal purge gas. This purge action removes contaminants and moisture, maintaining optimal conditions for chip production.

Additionally, helium is essential for plasma control and helps stabilize and enhance plasma processes essential for etching and deposition.

By providing a controlled environment, helium contributes to increased precision and reliability in semiconductor manufacturing, ensuring the development of advanced technologies and high-precision production.

Protection of chip integrity

In semiconductor manufacturing, maintaining an ultra-clean environment is essential to protect the integrity of chips. Contaminants such as dust, moisture, and chemical residues can significantly impair the performance of semiconductor devices.

Due to its inert properties, helium plays a key role in achieving and maintaining these ultra-clean conditions. It is often utilized in gas purging processes to eliminate contaminants and maintain atmospheric purity within manufacturing facilities.

In addition, helium acts as a carrier gas in various processes, ensuring that reactive gases do not interact with unwanted impurities. By minimizing the risk of contamination, helium significantly increases the reliability and lifetime of semiconductor components, ultimately improving the overall quality of electronic products in an increasingly demanding market.

Global helium supply challenges and impact on the semiconductor industry

As demand for semiconductors continues to soar, challenges surrounding global helium supplies are becoming more pronounced.

The limited availability of helium is primarily due to the decline of natural gas fields that produce helium as a by-product, and is further exacerbated by geopolitical tensions and economic factors affecting extraction and distribution.

These challenges can have a severe impact on the semiconductor industry, leading to increased production costs and delays in manufacturing schedules. Companies that rely on helium for critical processes can be at a competitive disadvantage, increasing the need for strategic planning and sourcing alternatives as the industry navigates these supply hurdles.

Innovation and alternatives: how the industry is preparing for the future

Amid the challenges posed by helium supply constraints, the semiconductor industry is actively seeking innovations and alternatives to reduce the risks associated with this critical resource.

Companies are investing in research to develop new materials and processes that reduce dependence on helium. For example, advances in plasma etching technology and the use of alternative gases are gaining attention.

Additionally, some companies are exploring recycling methods to reuse helium used during manufacturing and extend its lifecycle. Collaborative efforts with helium suppliers aim to secure long-term contracts and improve supply chain resilience.

These efforts not only address immediate concerns, but also position the semiconductor sector for growth in the future, when helium availability may become increasingly uncertain.

In conclusion, helium’s unique properties make it essential in semiconductor manufacturing to ensure accuracy and maintain the integrity of the chip manufacturing process.

With global supply issues threatening this critical resource, the industry must prioritize securing helium to maintain innovation and competitiveness.

Exploring alternative solutions and innovative techniques is critical to addressing these supply issues and ensuring that semiconductor technology continues to advance in the face of rising demand and evolving manufacturing complexity.

Source link