Major advances in the fight against persistent water pollution are underway in Illinois. There, national laboratories and local engineering firms are collaborating to develop next-generation water treatment systems that remove harmful PFAS chemicals.

The partnership combines the research power of Fermi National Accelerator Laboratory with the manufacturing and engineering expertise of Lisle-based Proficio Consultants to form a team focused on developing systems that work seamlessly with electron beam accelerator technology.

Tackling PFAS with cutting-edge science

PFAS, also known as “forever chemicals,” are widely used in everything from firefighting foam to household products.

Due to its molecular structure, it is highly resistant to decomposition and can accumulate in soils, waterways, and even drinking water sources.

Increasing evidence linking PFAS exposure to health concerns has fueled the search for effective removal methods.

Traditional filtration and chemical treatments are often insufficient to destroy PFAS or create secondary waste. However, electron beam technology has emerged as a promising alternative.

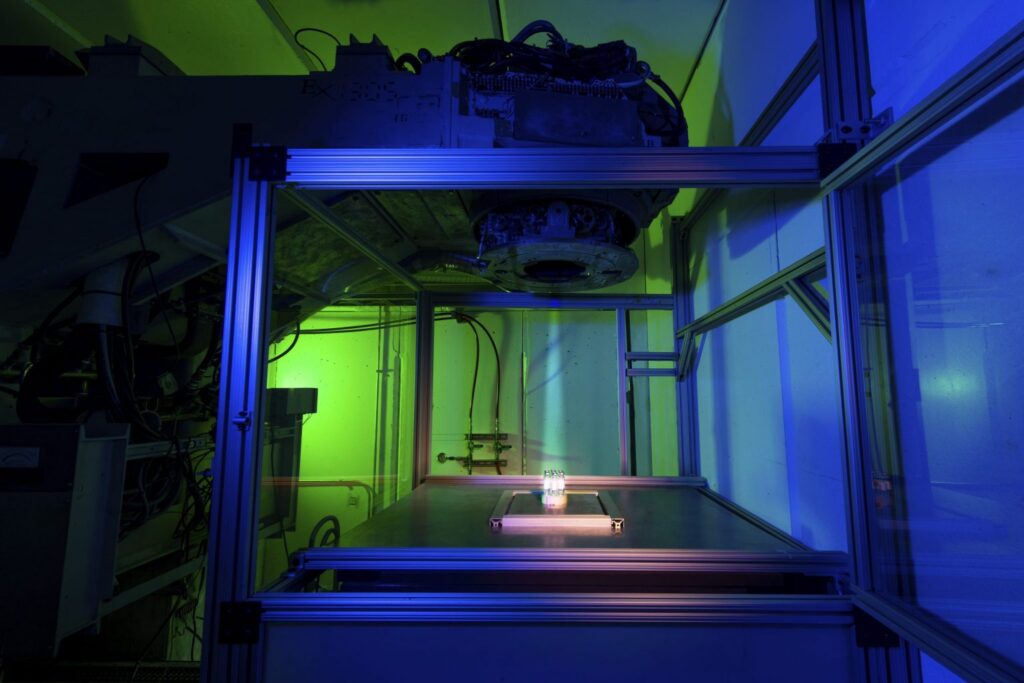

Researchers at the Illinois Accelerator Research Center (IARC), part of Fermilab, are developing a compact superconducting accelerator that can generate high-energy electrons that disrupt the chemical bonds that are at the heart of PFAS’s resilience.

IARC’s initial research shows that targeted electron irradiation can disrupt these carbon-fluorine bonds, greatly reducing the harmful effects of the resulting by-products.

Special systems for preparing and purifying water

To maximize the efficiency of electron beam processing, contaminated water must enter and leave the accelerator under strictly controlled conditions.

That’s where Proficio Consultancy’s new water treatment skids come into play. The company is designing a modular system that prepares PFAS-containing water for irradiation and then adjusts it to ensure the safety and efficiency of the process.

The planned skid will be directly integrated with Fermilab’s small accelerator and support continuous water flow for real-time processing. Its equipment monitors and controls key variables such as temperature, pH, dissolved oxygen, and feed rate.

By maintaining these parameters, the system ensures that the accelerator is operating at peak performance, allowing it to break down PFAS molecules as effectively as possible.

Engineers envision a unit that is flexible enough to adapt to a variety of operating conditions, from small-batch laboratory tests to large-scale pilot-scale demonstrations.

This adaptability allows the technology to evolve from a controlled research setup to a full-scale deployable water treatment system that can address contamination at industrial and municipal sites.

Paving the way to scalable environmental solutions

This collaboration represents multiple engineering projects. It highlights how national laboratories and small and medium-sized enterprises can work together to advance environmental innovation and accelerate the translation of cutting-edge research into real-world applications.

IARC continues its mission to make technologies developed at Fermilab available to industry, and solutions like PFAS destruction with electron beams may soon become a viable option for communities struggling with contaminated water supplies.

If successful, this new type of high-tech water treatment system could transform the way the nation combats PFAS contamination, turning advanced accelerators into a practical tool for creating cleaner, safer water.

Source link