Electronics are everywhere, from medicine and agriculture to packaging and logistics, but the way they are manufactured has long carried high environmental costs.

At the University of Tampere, Professor Matti Mäntysalo and his research group are challenging the status quo by advancing printed electronics and low-energy manufacturing methods that have the potential to fundamentally reshape the electronics industry.

This research covers the entire production system, rather than focusing only on individual components. The goal is clear. It’s about creating electronics that are flexible, scalable, and dramatically sustainable without sacrificing real-world usability.

Starting from manufacturing

Traditional electronics manufacturing relies on high temperatures, complex chemical processes, and material-intensive methods such as etching. Printed electronics completely flips that logic.

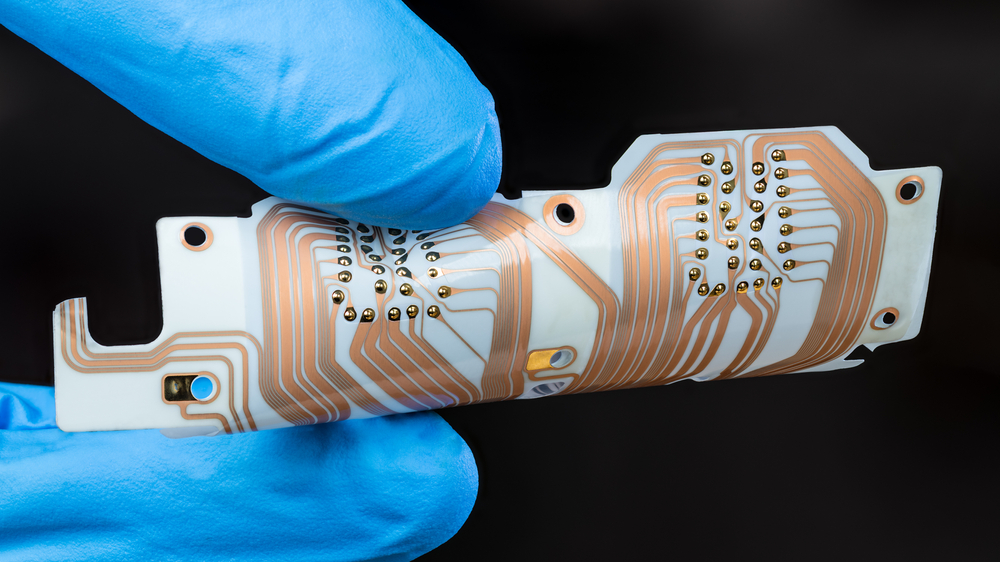

Using techniques adapted from the printing industry such as screen printing, inkjet printing, and roll-to-roll production, electronic components are built layer by layer, adding material only where it is needed. Conductive paths, sensors, capacitors, and even transistors can be printed directly onto flexible substrates.

This additive approach significantly reduces waste and chemical usage compared to traditional printed circuit board manufacturing. It also consumes significantly less energy, primarily due to much lower production temperatures.

Reducing energy use directly translates into reduced carbon emissions, creating clear and measurable sustainability benefits.

Lower temperatures also unlock the potential for new materials. Bio-based, biodegradable materials that would otherwise be destroyed by traditional high-temperature processes can now be used in functional electronics. This expands design space far beyond traditional metals and plastics.

Reduce dependence on critical raw materials

Another area of focus is reducing dependence on rare and potentially environmentally harmful raw materials. Many modern electronic components, especially batteries, rely on critical minerals that are difficult to source sustainably.

Mäntysalo’s group is exploring alternatives such as printed supercapacitors that can be made without many of these materials.

In some experimental settings, electronic functions can be achieved using surprisingly everyday materials such as carbon, salt, water, paper, aluminum, and small amounts of plastic.

The purpose is not to replace high-performance electronics in demanding applications, but to complement them. Many use cases, such as disposable sensors or simple monitoring devices, do not require maximum performance. Printed electronics allow designers to match material and energy use to actual functional needs.

When electronics are designed to disappear

One of the most radical ideas to emerge from this research is biodegradable electronics. At first glance, designing electronics that disassemble may seem counterintuitive.

However, as the number of connected devices grows into the billions and eventually trillions, the challenges at the end of their useful life cannot be ignored.

Many sensors are disposable in nature. Medical diagnostics, environmental monitoring, and agricultural applications often require devices that cannot be recovered or reused. In these cases, recycling alone is not enough.

The concept is simple but powerful. Design electronics that can safely decompose in the natural environment or enter existing paper and plastic recycling streams without harm.

This approach is being explored in the SOIL research project carried out in collaboration with VTT. This project focuses on biodegradable and flexible electronics for soil monitoring.

Sensors capable of wireless data transmission have been developed using materials commonly found in soil and combined with low-temperature additive manufacturing processes. Once the mission is completed, the device can be disassembled without changing the composition of the soil.

Printed electronics in healthcare and remote monitoring

Sustainability is not only environmental, but also social. Printed electronics has the potential to transform healthcare by enabling affordable and easy-to-manufacture diagnostic tools for home use.

Wearable and printed sensors can monitor vital signs such as heart rate, oxygen saturation, respiratory rate, body temperature, and cardiac function. Data can be sent wirelessly to a monitoring system that analyzes the results and issues alerts if necessary.

This model supports early diagnosis, reduces unnecessary hospital visits, and improves follow-up care after discharge.

This is especially valuable for sparsely populated areas where access to hospitals and specialty services may be limited. Printed electronics allow medical services to be delivered to patients rather than the other way around.

Finland’s strong position in Pinto electronics

Printed electronics is a global field, but Finland has an unusually strong position. The country ranks as one of the world’s leading scientific publications on printed electronics, and also ranks near the top relative to population size.

This leadership is rooted in a unique industrial continuum that brings together forestry, coatings technology, electronics expertise and Nokia’s heritage. Collaboration between universities, research institutes and industry will play a central role.

One of the main examples is the EU-funded Sutronics project. The project brings together dozens of partners across Europe to address sustainability challenges in the electronics sector. Finnish participants include Tampere University, VTT and several technology companies, which receive state funding from Business Finland.

This project focuses on redesigning existing electronic products and developing entirely new products using sustainable principles.

Educating the next generation of electronics professionals

Developing sustainable electronics also requires new types of expertise. Mantisaro emphasizes the importance of a strong foundation in physics, chemistry, and mathematics, rather than early overspecialization.

At doctoral level, Tampere University is working on several initiatives aimed at strengthening Europe’s microelectronics expertise. The EU-funded FERNS Doctoral Network trains researchers to think in terms of the circular economy, bio-based materials and low-energy processes.

Additional national programs provide a direct link between doctoral research and industry, allowing graduates to move smoothly into applied fields.

Building tomorrow’s electronics

For Mentisaro, printed electronics are more than just a technological change, they embody new ways of thinking about how electronics are designed, manufactured, used and ultimately put back into the material cycle.

At a time when sustainability has become a defining issue for the electronics industry, that idea could prove to be as important as a single innovation.

Source link