The E-OilÉ Horizon Europe project is rethinking how single-dose packaging is used in the food and cosmetics sector.

The packaging industry is the source of around 40% of the planet’s plastic waste¹ and Europe’s plastics and materials industry is facing a critical moment.

Plastic waste, regulatory demands, and growing consumer awareness are forcing companies to find alternatives that are not only sustainable, but also functional, scalable, and economically competitive. The European Union (EU) is at the forefront of packaging waste regulation, and central to this effort is the recently adopted Packaging and Packaging Waste Regulation (PPWR). The regulation will come into force in 2025 and replace the long-standing Packaging and Packaging Waste Directive.

PPWR establishes binding requirements for all packaging materials placed on the EU market, including design standards, recyclability, recycled content thresholds and measures to minimize waste throughout the packaging material’s lifecycle. The main objective is to make all packaging recyclable in an economically viable manner by 2030, while significantly reducing reliance on virgin materials and increasing resource efficiency in line with the European Green Deal and wider circular economy goals.

In the food and cosmetics packaging sector, this regulatory change brings both challenges and opportunities. Disposable packaging, especially single-dose packaging, has become an essential part of modern life. Hygiene, safety, accurate dosing, and convenience are guaranteed across food, pharmaceutical, cosmetics, and other sectors. However, these formats are very difficult to recycle due to their small size, contamination, and multilayer structure. The same challenges apply to many complex plastic applications. Traditional recycling is not efficient or economically viable. In this context, compostable or biodegradable is increasingly recognized as a worthwhile and safe alternative to consider.

E-OilÉ: Biodegradable by design, sustainable by nature

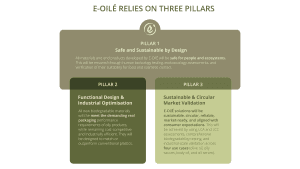

The E-OilÉ project aims to demonstrate a safe and sustainable disposal route for single-use single-use packaging for oil-based products. It also focuses on replacing fossil-based polymers such as polypropylene (PP) and polyethylene terephthalate (PET) by developing two complete value chains of biodegradable polymers and materials.

E-OILE aims to develop two types of biodegradable compounds in TRL7 and aims to:

We develop novel biodegradable biopolyester grades obtained from biobased components (lcDCA obtained from the fermentation of sugar and used cooking oil, oleic acid-rich olive production waste, and sebacic acid obtained from castor oil) (TRL 5-7). Develop new bio-based and biodegradable polysaccharide-based grades.

iii. Develop and produce at least four optimized single-use packages for oil-based products in three industrial plants at TRL 6-7 for four use cases that will be validated from a performance and safety perspective (see Figure 1).

UC1 – Olive oil: Thermoformed cup UC2 – Oily sauce: Flexible sachet UC3 – Body oil: Tube extrusion and overinjection molding UC4 – Cosmetic face oil serum: Flexible sachet

What innovative solutions does E-OilÉ offer?

The main innovations of this project are aimed at increasing productivity, reducing costs and improving material performance in continuous industrial plants such as:

Use of non-ecotoxic and sustainable catalysts. Development of masterbatches with food contact approved additives that can be used efficiently during processing and packaging. Ecodesign strategy based on minimization of multilayer approach. Advanced process monitoring and parameter optimization across a variety of technologies, including extrusion (casting and blowing), coating, tube extrusion, head-over molding and thermoforming lines.

Furthermore, a key differentiator of this project lies not only in the rigorous validation of the E-OilÉ solution in the food and cosmetics end-user line sectors, but also in the end-of-life, where open environment biodegradation testing is used, along with artificial intelligence (AI)-assisted biodegradation prediction models. AI will also be applied to validate smart sensors in case this type of packaging reaches recycling.

Beyond the technical aspects, we recognize that true success depends on economic viability and social acceptance. That is why a thorough economic impact assessment will be carried out in parallel with efforts through the social sciences and humanities.

The project brings together 15 E-OilÉ partners from nine countries, representing key strategic actors across the packaging value chain, large and small businesses, material producers, manufacturers and end users. The consortium is further strengthened by RTOs and non-profit organizations with expertise in Safe-and-Sustainable-by-Design (SSbD), biodegradation testing, risk assessment, packaging and product validation, utilization strategies, SSH, and digital technologies.

In summary, E-Oilé aims to bring new packaging solutions to the market by venturing into biodegradable, single-dose format packaging innovation, leveraging enabling EU regulations, and integrating innovative compostable material science and circular design principles. Six months into the project, the project has successfully demonstrated the conversion of oleic acid-rich waste from olive oil production into a critical biopolyester building block. Don’t miss what happens next and follow us.

This project received funding from the European Union’s Horizon Europe research and innovation program under grant agreement number 101177771.

References

https://ourworldindata.org/data-insights/packaging-is-the-source-of-40-of-the-planets-plastic-waste

Please note: This is a commercial profile

This article will also be published in the quarterly magazine issue 25.

Source link