The BMBF-funded IFE Targetry Hub project was launched at the end of 2024 with the aim of investigating basic target manufacturing and fielding techniques for laser-based inertial confinement fusion in Germany.

Nuclear fusion has great potential to solve the problems of energy demand around the world. Laser-driven inertial fusion is the only scheme to demonstrate scientific net energy gains, but the engineering challenges for implementing reliable fusion techniques and building commercially viable fusion power plants It’s still there.

The German joint project, under the leadership of the Fraunhofer Institute for Applied Solid State Physics (IAF) and Focused Energy GmbH, consists of 15 partners in research and industry, and has launched research on so-called targets. This important component of laser-based inertial confinement fusions includes the hydrogen fusion fuel and the ablator material required to compress and fuse hydrogen isotopic hydrogen and tritium.

Fusion Promise: Global Energy Solutions

Following the initial successful demonstration of heavy water and tritium fusion and burns at the Lawrence Livermore National Laboratory, interest in fusion technology has grown rapidly worldwide. However, there is still a long way to go before commercially using nuclear fusion as a sustainable energy source that provides great value to society. The BMBF-funded project, “IFE Targetry Hub for DT Inertial Fusion” (IFE Targetry Hub), currently lays an important foundation for the study of laser-based inertial fusion in Germany.

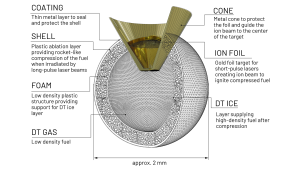

All forms of laser-driven inertial confinement fusion are pulsed processes in which a target filled with hydrogen isotope hydrogen and tritium isotope compressed and fired using many high-energy laser beams as drivers. It reaches temperatures up to 120 million degrees Celsius, evaporates the target, and simultaneously heats and compresses the fuel to heat and compress the solid density multiple times. This allows for a fusion reaction in which actively charged atomic nuclei overcome mutual repulsion and fusion to form helium while releasing enormous amounts of energy.

For example, research and development is still needed to improve the properties of existing targets in terms of yield and reproducibility, to ensure the qualitative advances required for power plant development. Current targets are measured and characterized over a wide range of areas so that the results of fusion experiments can be compared with simulations.

The fundamental ability to generate targets with properties suitable for fusion is important in realizing fusion power plants. Commercially viable power plants need to significantly reduce costs per target with a repetition rate of shots above 10° per day. In the case of targets successfully tested with LLNL and created by diamond materials, a partner of this consortium, individual production is cutting edge.

IFE Targetry Hub Initiative

The IFE Targetry Hub project, on the one hand, aims to develop concepts that improve fusion properties and enable verifiable progress, but at the same time, it can be manufactured more than ever before.

The supply of materials for the injection and fixation of fused fuel is of paramount importance to power plants. As previous fusion experiments have shown, the quality of the compression target is an important skill in IFE and determines the key success factors. The fusion target is injected into the reactor chamber at high speed, produced in sufficient quantities, and characterized, while meeting immeasurable qualitative requirements (materials, geometric, thermal, mechanical parameters) and retaining its properties. must be tested and inspected. For reproducibility.

Documentation and process-based creation, and characterization criteria, are prerequisites for this project. This project combines essentially available and foreseeable technologies so that both production and suitable and innovative characterization methods are developed. As for manufacturing methods, the ultimate goal should be to improve material quality so that 100% control can be avoided forever using statistical controls.

At IFE Targetry Hub, our partners offer a range of expertise covering basic, applied research and industry, and functional and cost-effective scalable production and characteristics of hydrogen fuel economy for laser-based inertial confinement fusion We collaborate on materials and processes suitable for evaluation. These targets represent bottlenecks for efficient fusion, and are important technologies on the way to future laser-based fusion power plants.

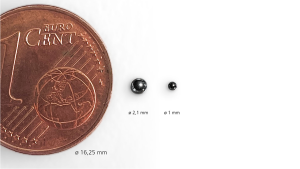

Previous demonstrations used a spherical diamond target with a diameter of 1 mm. Target geometry, interface properties, purity, and material quality are important for successful fusion. IFE Targetry Hub currently develops and implements high-precision manufacturing processes, including manufacturing foam additives and characterizing target components. The aim of this study is scalable target production that meets the high requirements for successful laser-based inertial confinement fusion.

Advances in target production of laser-based inertial fusions

The purpose of the IFE Targetry Hub joint project is to form the basis for materials, processes and characterization for the simultaneous production of functional and cost-effective targets for laser-based inertial fusion. Based on the development of a new high density carbon (HDC) diamond target, the HDC target with new silicon doping is similar to the previous tungsten-based HDC target. In deriving the findings from HDC development, the objective is to study manufacturing processes that allow for simultaneous production of targets at an initial number of at least 5,000 units. So far, available HDC manufacturing technologies can only generate high quality targets up to 1/10.

Many target production developments are based on evidence based on analysis of material quality achieved through fusion testing (firing). Based on existing experimental results, criteria for material evaluation for repeated fusions have been developed. To this end, both simulation and characterization have been established.

Additionally, the manufacturing process for polymer target additives has been developed and investigated, producing bubbles and in combination with atmospheric pressure plasma technology, modifying them and embedding them into low-pollution flow streams. This can allow for very high production rates at low process costs after proof of compatibility for fusion.

Already established 2PP printing techniques with point-point interactions have been improved in terms of achievable resolution, and in parallel, a new type of 2PP projection lithography has been developed to print time for IFE targets It’s significantly shortened. To capture large numbers of targets using static characterization methods, a new statistical characterization method using microwave resonators and X-ray tomography must be developed.

Possibility is created to measure important parameters of these materials at cryogenic temperatures used in IFE targets. Additionally, a test stand is implemented to test the behavior of IFE forms and integrated forms and ablation spherical shell targets. This can be examined when liquid hydrogen is filled through microcapillaries.

Microcomponents should be characterized before use as IFE targets in laser plasma experiments or initial fusion test reactors. There are only a few requirements for the purity of the material of the ablation spherical shell, concentricity, sphericality, and uniformity of the DT ice-filled foam, for example, the position of the cone of the spherical shell for proton high-speed firing. Quality parameters that must be determined with the highest accuracy. To this end, specific measurement devices have been developed and qualified as part of this research project.

After successful demonstration of medium-volume functional target production processes under laboratory conditions, the results show that the progression of the production process required to produce sufficiently large numbers of targets for commercial reactor operations. It is incorporated into sexual development.

The company-focused Energy GMBH, along with other industrial partners, has transferred the positive results of research funding over the last three years to the subsequent development stage, and has been developed for IFE target production by each project partner. We will verify the process and product at once. .

The IFE target hub is funded by the Federal Ministry of Education and Research BMBF. Fraunhofer IAF and focused energy GMBH coordinate the project consortium.

Concentrated Energy Gmbh Karlsruhe Institute – Tritium Institute Karlsruhe (kit-tlk) Darmstadt Institute of Nuclear Physics (IKP) Nano and Microfluidic Research Institute (NMF) Production Engineering and Formation of Machining Machines (PTU) Kern Microtechnik Fraunhofer -Gesellschaft zurförderungder angewandten forschung e. V. Fraunhofer Applied Solid State Physics IAF (Coordinator) Laser Technology Ilt Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM Fraunhofer Institute for Integrated Circuits IIS IIS-Development Center X-Ray Technology Ezrt Gmbh Lightfab gmbh Modulwabh Gmbh Herkula Farben Gmbh

This work was funded by the German Federal Ministry of Education and Research, BMBF, initiative IFE Targetry Hub, FKZ:13F1013A.

Dr. Thomas Kuschel, supporter of the VDI Technology Center, is highly recognized.

This article will also be featured in the 21st edition of Quarterly Publication.

Source link