Vikram Rathore from Uppsala University explores the findings from a study evaluating the fuel performance of a small modular reactor under load-following operation.

Rising energy demands, coupled with the urgent need to reduce reliance on fossil fuels, have driven extensive research into sustainable, cleaner, and more economical energy sources. Among the various alternatives, nuclear energy is poised to play a crucial role in future energy systems, despite its historical association with high capital expenditures and concerns over radiation safety. However, small modular reactors (SMRs) have gained increasing attention in recent years and are regarded as transformative solutions to some of the challenges associated with nuclear energy. SMRs are smaller in both physical size and energy output compared to conventional reactors,¹ and can be manufactured more rapidly and cost-effectively. Their modularity enables widespread deployment for distributed electricity generation and heat production, thereby making nuclear energy more accessible and less expensive.

Development of small modular reactors

Numerous SMR designs, tailored for a variety of end uses, are under development globally. These designs are at different stages of development, with some being described as ready for near-term deployment. Many SMRs are designed based on established large-scale reactors, primarily light water reactors (LWRs), which may reduce the need for extensive research and development. This approach allows them to leverage the rich and extensive operational experience gained from LWRs. There is about 20,000 years of reactor operation (IAEA Nuclear power reactors in the world, 2024), the majority of which are from LWRs operating on uranium oxide (UOX) fuel. Still, the reduced core sizes in SMRs, as well as changes in operation mode, or other system changes to increase modularity, can still present some differences in the fuel operation regime, with possible implications for fuel behaviour and operational limits.

To support the development of SMRs in Sweden, a national competence centre, the Academic-industrial Nuclear technology Initiative to Achieve a sustainable energy future (ANItA),² was established in 2021. The centre brings together academia and industry to drive a diverse range of research projects, addressing both technical challenges and broader societal considerations related to the future deployment of SMRs. Although most SMR designs resemble conventional large nuclear reactors, there are subtle differences, such as reactor core size, fuel composition, and mode of operation. Identifying these differences and studying their effects on fuel performance is one of the key undertakings of the ANItA initiative.

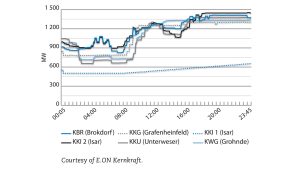

It is both anticipated and desirable that SMRs will operate under load-following conditions to better integrate with intermittent renewable energy sources. Load-following operation means adjusting the power output of a nuclear reactor to match changes in electricity demand. See the figure³ above for a reference on how power output varies during load-following operation in German nuclear power plants.

Load-following operation in nuclear power plants⁴ is not new and has been used for many years. However, the current experience of such operations may not be sufficient to ensure the safe and efficient operation of SMRs under these conditions, as there is no real-world operating experience with SMRs to date. Moreover, power cycling (variation in heat output), which could be rapid or slow – corresponding to demand and supply variations from hourly, daily to seasonal variations – may also be concerning for the fuel. The most common form of fuel in nuclear reactors is the cylindrical fuel rod, which is made of a hollow tube typically made of zirconium alloys (also known as a cladding), containing a stack of small uranium dioxide (UO2) pellets. A very thin gap between the pellets and the cladding accommodates the fission gases generated during the operation. For the safe operation of a nuclear reactor, the cladding must remain intact while efficiently transporting the heat generated within the pellets and retaining the radioactive fission products.

What happens to nuclear fuel during load-following, and how can we study the effects?

Power cycling in load-following operation causes large variations in the temperature of the fuel pellets and cladding, which in turn affects several phenomena important to nuclear fuel performance. Most notably, the mechanical interaction between the pellet and the cladding, also known as pellet cladding mechanical interaction (PCMI), caused by repeated thermal stresses, can be problematic for the cladding. These stresses, combined with corrosive fission products, may weaken the cladding over the long term and, in some cases, lead to its eventual failure.⁵

Therefore, it is essential to study fuel performance under load-following conditions to ensure that it functions as intended and remains safe. In principle, this can be done both by experimental observation and computational means. Experimental studies of load-follow operation on nuclear fuel would require dedicated, long-term irradiations in test reactors, with provisions to control the fuel reactivity according to the desired load-follow pattern. However, such experiments would be prohibitively expensive, particularly if the aim were to perform a parametric study in which load-follow parameters are systematically varied to evaluate their correlation with fuel failure mechanisms.

An alternative is to study load-follow operation in commercial power reactors using standard fuel, with subsequent post-irradiation examinations to identify possible effects. This approach, however, does not allow for broad exploration of different load-follow patterns, since the primary requirement for all power reactor operation is to ensure safe and uninterrupted electricity production, generally within or close to established operational experience.

For this reason, computational studies remain a reasonable choice for exploratory analyses. By applying advanced fuel performance codes, a wide range of load-follow parameters can be simulated to assess their impact on the thermo-mechanical performance and potential degradation of the fuel. Such computational investigations can serve as a first scoping step, helping to identify promising areas for more detailed experimental or analytical follow-up.

Computational methods allow for unlimited, controlled variation in load-following operation modes, offering the flexibility to explore scenarios beyond historical practices. However, they are limited by the capabilities and accuracy of the computational models used to simulate highly complex physical phenomena. Nonetheless, simulating these operations using computational methods serves as a valuable foundation for examining their impacts. The outcomes can inform future research efforts, such as observational studies of irradiated nuclear fuel, irradiation experiments, and ongoing enhancements to the models within fuel performance codes.

There are several computer codes, such as TRANSURANUS,⁶ FRAPCON,⁷ and ENIGMA,⁸ available to study the performance of nuclear fuels under various operating conditions. These codes can provide comprehensive thermo-mechanical analysis of fuel rods, and most of the models within them are validated against experimental data. The codes need input data detailing the fuel design (including dimensions and material properties) as well as the power history, which covers irradiation conditions like linear heat rate, neutron flux, and coolant mass flow rate. The output data produced by the codes provide various fuel performance parameters, including temperatures, pressures, stresses, strains, fission gas release, and burnup.

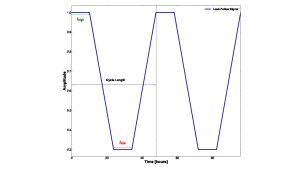

Here, we present selected results from a study conducted using TRANSURANUS⁹ to analyse the fuel performance of a LWR-based SMR under load-following operation. However, as operational data and fuel histories for SMRs are not yet publicly available, the study has utilised fuel rod data and power histories from a large pressurised water reactor (PWR). Hypothetical load-following operation scenarios were simulated by adjusting the linear heat rate, neutron flux, and coolant flow rate. These adjustments were guided by a parametrised load-following signal, with key parameters including cycle length, power reduction, and transition rate. These parameter values were chosen based on insights from an NREL Technical Report,10 which offered guidance on appropriate ranges for each. For reference, power profile of a fuel rod, both in normal and load-following operation, is shown in the next figure.

Interpreting the simulation results

As mentioned earlier, fuel performance codes provide various output quantities related to the thermomechanical behaviour of the fuel pellet and cladding. The parameters that were deemed most important and chosen for analysis include fuel centreline temperature, cladding hoop (circumferential) stress and strain, fractional fission gas release, rod average burnup, gap width, hydrogen absorption, cladding oxide thickness, and cladding deformation.

For the safe operation of a nuclear reactor, critical limits for many of these parameters are set by regulatory authorities and must not be exceeded – for example, the peak cladding temperature must not surpass 1,200°C. These parameters can therefore be assessed directly from the simulation results. Since the integrity of the cladding is crucial to safety, its hoop stress profile over time can be analysed to evaluate its structural strength during reactor operation. TRANSURANUS also includes models that estimate the initiation of cracks in the cladding caused by corrosive species and elevated hoop stress levels.

It is not possible to present results for all simulation cases; however, it is worth noting that all fuel performance parameters indicated that the maximum values during load-following operation were generally similar to, or lower than, those observed under normal operation, and all remained well within the prescribed safety limits. The major exception to this, observed in the load-following cases, was the occurrence of cladding cracks caused by pellet–cladding interaction and corrosive species. However, this result should be interpreted with caution, as the specific model used to calculate this in TRANSURANUS is a standalone model without feedback mechanisms and has previously produced erroneous predictions.

What do the results indicate – good, bad, or neutral?

The answer is not straightforward; in fact, the results provide only a limited basis for drawing any definitive conclusions. On the one hand, it is reassuring that none of the fuel performance parameters approached their critical safety limits. This may be interpreted as neutral or cautiously optimistic. On the other hand, the occurrence of cladding cracks, with some predicted to penetrate the full cladding thickness, is a serious concern and must be regarded as a negative outcome. However, it is important to emphasise that these findings are entirely based on simulations performed using TRANSURANUS. While many of its models have been validated and are known to closely reproduce experimental observations, others still require significant improvement, further validation, and comprehensive uncertainty quantification.

It is essential to acknowledge the constraints of our study, many of which stem from simplifications made during the modelling process. For instance, the linear heat rate was uniformly modified along the entire length of the fuel rod during power cycling – a simplification that may not accurately capture the reality of reactor operation, where axial power profiles are influenced by the specific reactivity control strategies used in a given SMR design. In practice, non-uniformities such as those caused by control rod insertion, can significantly affect local temperatures, stress distributions in the cladding, and power peaking effects. Moreover, the power history data employed in this analysis originates from a large commercial PWR, which may not be directly representative of SMR operational characteristics. SMRs typically have smaller cores, fewer options for core loading arrangements, more complex burnable absorber designs, and advanced control systems, all of which could lead to markedly different performance outcomes. Although this study explored various load-following signals by altering key parameters randomly and independently, a more nuanced approach could provide greater realism. Finally, extending such analyses to other SMR types such as the BWRX-300, which proposes to use natural circulation for cooling, would offer valuable insights into how design-specific features influence fuel performance under flexible operation modes.

Therefore, it is too early to determine whether the outcome is good, bad, or neutral. However, we can point to the PCI phenomenon, and the predictive capability of the effect of load-follow on the same appears as a topic requiring further study.

References

The NEA small modular reactor dashboard: Second edition.

Ane Håkansson. ANItA – A new Swedish national competence centre in new nuclear power technology. Nuclear Engineering and Design, 418:112871, March 2024

A. Lokhov. Load-following with nuclear power plants. OECD-NEA, 2011

Power ramping, cycling and load following behaviour of water reactor fuel. IAEA, 1988

K. Videm, L. Lunde, T. Hollowell, K. Vilpponen, and C. Vitanza. Cracking of cladding tubes caused by power ramping and by laboratory stress corrosion experiments. Journal of Nuclear Materials, 87(2):259–267, December 1979

K. Lassmann. TRANSURANUS: a fuel rod analysis code ready for use. Journal of Nuclear Materials, 188:295–302, June 1992

G A Berna, G A Beyer, K L Davis, and D D Lanning. Frapcon- 3: A computer code for the calculation of steady-state, thermal- mechanical behavior of oxide fuel rods for high burnup. Technical report, US Nuclear Regulatory Commission (NRC), Washington, DC (United States). Div. of Systems Technology; Pacific Northwest National Lab. (PNNL), Richland, WA (United States); Idaho National Lab. (INL), Idaho Falls, ID (United States), 12 1997

P.A. Jackson, J.A. Turnbull, and R.J. White. Enigma fuel performance code. Nuclear Energy, 29(2):107–114, Apr 1990

Vikram Rathore, Paul Blair, Gustav Robertson, Martin Jonson, and Peter Andersson. Study of load-following operation impact on light water reactor fuel performance using TRANSURANUS. Frontiers in Energy Research, 13, 2025

A Sowder, S Bernhoft, and D Moneghan. Expanding the Concept of Nuclear Flexibility for the Current Fleet and the Next Generation of Advanced Reactors. Technical report, NREL Technical Report, 2020

Please note, this article will also appear in the 24th edition of our quarterly publication.

Source link