In the global race to tackle ‘forever chemicals’, PFASuiki is turning ambition into action. The startup is scaling up its breakthrough electrochemical oxidation (EO) system and expanding its team of engineers, scientists, and field experts to achieve permanent PFAS destruction.

PFAS (per- and polyfluoroalkyl substances) are a class of over 10,000 synthetic compounds valued for their water and heat resistance, but notorious for their persistence. They accumulate over decades and pose serious health and ecological risks. Traditional water treatment systems only capture PFAS, not destroy them.

PFASuiki’s approach is different. PFASuiki’s EO technology uses precisely engineered electrodes and a unique system design to break the carbon and fluorine bonds that make PFAS nearly indestructible. The result is true petrification, with permanent removal rather than displacement.

ESG and regulatory background

PFAS are increasingly recognized as the defining environmental issue of our generation. Governments are tightening regulations, waste treatment costs are rising, and the industry is under increased scrutiny.

The EU and several member states are moving towards phasing out PFAS and banning incineration. The cost of disposing of waste contaminated with PFAS can exceed €2,000 to €3,000 per tonne. Global lawsuits over PFAS contamination have already reached billions of dollars in damages.

On-site PFAS destruction provides a clear path to compliance, cost control, and ESG leadership. PFASuiki’s modular EO system makes this possible with a sustainable and future-proof solution.

From concept to function: turning research into results

Since its founding, PFASuiki has been driven by a clear mission: to transform the destruction of PFAS from a laboratory curiosity into an industrial reality.

Born out of TDK, a globally recognized Japanese electronics company, PFASuiki benefits from world-class materials expertise and engineering depth. Now, as an independent startup, the company combines its heritage with startup agility, building, testing, and refining systems in its own labs to deliver faster, smarter results.

We now have a growing team of chemists and engineers taking this innovation from prototype to pilot scale. Hands-on development, rigorous analysis, and continuous testing are at the heart of PFASuiki’s progress.

How it works: Precisely engineered PFAS destruction

Electrochemical oxidation is not new, but PFASuiki’s version is.

Advanced electrode materials and system structure provide high efficiency and long operating life. Here’s what’s great about this technology:

Direct electron transfer (DET) enables targeted degradation of PFAS molecules at the electrode surface. Indirect oxidation by radical species increases overall destruction efficiency and simultaneously addresses PFAS and other organics. Recyclable electrode materials reduce environmental impact and operating costs. Modular system design allows easy expansion of technology from pilot setup to industrial wastewater plants.

The result is a highly efficient PFAS destruction system that operates with minimal chemical additives and competitive energy inputs (on the order of 15-30 kWh/m3/m3).

Proven in complex environments: Landfill leachate challenges

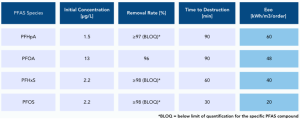

Among the most severe PFAS matrices is landfill leachate, which is a mixture of organics, salts, and various contaminants. PFASuiki’s prototype system has already demonstrated that real-world performance matches laboratory results.

Destroys 95% of PFAS in long chain compounds (PFHpA, PFOA, PFHxS, PFOS) in 30-90 minutes. Stable operation even with high organic loads (total carbon >4.5 g/L). Continuous optimization increases the likelihood that short-chain PFAS will degrade.

These results demonstrate that PFASuiki’s EO system can treat complex, high-intensity wastewater, paving the way for scalable PFAS destruction in landfills, chemical plants, and industrial sites.

Why PFASuiki’s solution is better

While there are many approaches that promise to eliminate PFAS, few can truly eliminate them. PFASuiki’s technology allows clients to close the loop on capturing and destroying PFAS on-site without creating new waste or liability.

Main advantages:

Permanent destruction: Breaks down PFAS into harmless components. Energy efficiency: Optimized electrodes reduce power demand. Plug-and-play operation: Easily integrates with existing treatment infrastructure. Low maintenance: Durable, long-life electrode material minimizes downtime. Environmental Responsibility: Contains no chemical additives and no cross-contamination.

Expanding your impact: From destroying PFAS to comprehensive PFAS solutions

PFASuiki’s core strength lies in its advanced electrochemical system for destroying PFAS in water, providing a permanent and sustainable solution to one of the most difficult contamination pathways.

At the same time, PFASuiki has already evolved beyond pure technology development to become a comprehensive PFAS solutions partner, supporting clients throughout the entire PFAS management lifecycle.

Are you ready to take action?

Become a pilot customer and experience how PFASuiki’s technology can deliver permanent, compliant, and sustainable PFAS destruction. Contact us to discuss a pilot project tailored to your site or application.

This article will be published in an upcoming PFAS Special Focus Publication in January.

Source link