The EU’s growing demand for rare earth magnets threatens the energy transition due to geopolitical dependence and a currently uncompetitive European industry.

Europe’s transition to sustainable energy and mobility is the cornerstone of major policy initiatives such as the Green Deal, Fit for 55 and REPowerEU. Central to this transition are permanent magnets. Permanent magnets are critical components of electric vehicles, wind turbines, industrial motors, and countless new technologies. Currently, the most powerful of these magnets are based on rare earth elements (REEs), particularly neodymium-iron-boron (NdFeB) alloys. Its outstanding performance results from the unique interaction between its electronic structure and crystal lattice, which forces the atomic magnetic moments to align along preferred crystallographic directions. This phenomenon, known as magnetocrystalline anisotropy, results in both high magnetization (due to iron) and strong coercivity (due to neodymium).

Importance of REE-free magnets

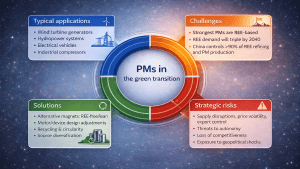

However, this technological advantage comes with increasing challenges. By 2040, global demand for REEs, particularly for permanent magnets used in electric vehicles and wind turbines, is expected to more than triple. The extraction, refining, and manufacturing of REE-based magnets is concentrated in several geographic regions and is deeply affected by geopolitical tensions. This creates significant economic vulnerability for Europe, whose REE industry is currently unable to compete with China without public support. These concerns, along with environmental considerations, highlight the need for alternative magnet technologies. Figure 1 illustrates the important role of permanent magnets in the green transition and the obstacles associated with the current supply chain.

One viable route is to combine REE-free magnets with smart engineering of components and devices. Although such magnets cannot yet match the absolute performance of NdFeB systems, their use in redesigned motors and generators could significantly improve sustainability, reduce market dependence, and strengthen the resilience of European industry.

Among the most promising REE-free candidates are aluminum, nickel, cobalt, and iron-based magnets (known collectively as alnico magnets). Unlike REE magnets, AlNiCo materials have relatively low magnetocrystalline anisotropy because the electronic structure and crystal symmetry of the elements are not synergistically aligned. To compensate, their magnetic performance strongly depends on shape anisotropy, i.e., the alignment of magnetic nanorods along specific crystallographic directions. Within each columnar particle, these nanorods form magnetic domains separated by domain walls, allowing the material to exhibit directional magnetic behavior.

The main advantage of alnico magnets is their excellent performance at high temperatures. While NdFeB magnets begin to lose their coercivity when heated, AlNiCo magnets maintain their coercivity, making them attractive for high-temperature applications.

A promising solution: the MagNEO approach

The MagNEO project brings together a diverse consortium of 16 partners from 10 European countries, spanning research institutes, advanced manufacturing companies, technology providers, universities, and skills development and communication experts.

Its overarching objective is to develop and implement advanced additive manufacturing (AM) strategies that allow REE-free alnico magnets to replace or complement traditional REE-based permanent magnets. This work integrates experimental studies, computational modeling, and data-driven optimization.

The project also focuses on sustainability. MagNEO will develop new recycling strategies and validate the performance of next-generation magnets in several key application areas.

Automotive and high-speed devices such as anti-lock braking systems, headlights, and heat pump motors. Low speed direct drive generator for wind turbines. Marine electric propulsion system.

The project concept is shown in Figure 2.

Central to MagNEO’s approach is an agile and flexible design methodology that combines experimentation, modeling, and optimization tools. This project advances both materials and manufacturing. This includes optimizing raw material production through gas atomization and extensive exploration of additive manufacturing techniques. AM has several sustainability benefits. It reduces raw material usage compared to traditional permanent magnet manufacturing, enables near-net-shape manufacturing of complex components, and allows material left over from the printing process to be reprocessed and reused.

Beyond materials and manufacturing, MagNEO includes component-level design and feasibility studies with industrial end users. Circularity is another central pillar of the project. The company’s recycling strategy includes:

Directly recycles long-lived powders, AM scrap, and used magnets by remelting and atomizing them into new alloy powders. We manufacture bonded magnets by directly recycling crushed used magnets. Indirect recycling using green chemistry technology selectively recovers critical metals such as cobalt, nickel and copper.

These practices have great potential to reduce the demand for virgin materials and close the loop on magnet production.

overcome challenges

To achieve its goals, MagNEO is currently tackling several complex scientific and technical challenges.

Ensures structural integrity of additively manufactured alloy components. We develop the correct grain organization at the microstructural level and align it along the desired magnetization direction, ensuring strong directional magnetic behavior. Forms well-aligned FeCo-rich microcrystals on the nanoscale and enhances shape anisotropy with precise shape and spacing.

Addressing these challenges requires precise control of material structure at multiple scales, from nanometer-level phase structure to large-scale grain orientation, both during additive manufacturing and subsequent thermomagnetic processing steps.

Enhancing the magnetic properties of gap permanent magnets, which bridge the performance gap between low-cost ferrites and high-performance rare earth magnets such as alnico magnets, is a technically challenging task that requires extended development schedules. Advances will need to be tightly integrated with the design of motors, generators, and other devices that use these magnets. Adaptation, both in terms of materials and engineering, is essential to realize the full potential.

Finally, recycling is important to Europe’s long-term position in magnet manufacturing. Developing robust circular processes enhances material safety, supports industrial competitiveness, and reduces environmental impact.

The MagNEO project aims to help Europe build a more sustainable and resilient future for magnetic technology through a multidisciplinary approach spanning innovative materials, advanced manufacturing, device integration and circular design.

Disclaimer

Funded by the European Union. However, the views and opinions expressed are those of the authors alone and do not necessarily reflect those of the European Union or the European Health Digital Administration Agency (HADEA). Neither the European Union nor the licensing authorities can be held responsible for them.

Please note: This is a commercial profile

This article will also be published in the quarterly magazine issue 25.

Source link