The Graphene Flagship is driving innovation in the energy sector by helping to develop game-changing electronics and energy storage solutions using graphene.

Graphene was first isolated in 2004. Over the past 20 years, graphene has found hundreds of innovative applications, from sensors and electronics to energy storage and harvesting.

What is graphene?

Graphene is the world’s thinnest material – at one atom thick, it is one million times thinner than a human hair. However, it is stronger than steel and diamond. Its outstanding stiffness and durability make it ideal for composite materials. Graphene is also very flexible, which creates opportunities for wearable device applications.

Graphene is also a great conductor of electricity and heat. Some producers have used these two principles to make conductive inks and paints for electronic circuits and gels that dissipate heat. Graphene’s conductive properties can even make longer-lasting batteries.

And, of course, graphene is light. The automotive and aviation industries are using graphene to reduce the weight of cars and planes, which will lower fuel consumption and carbon emissions.

The Graphene Flagship

In 2013, the European Union funded the Graphene Flagship – a new form of joint, co-ordinated research on an unprecedented scale, forming Europe’s biggest ever research initiative tasked with bringing graphene out of academic laboratories and into industrial applications.

Now made up of 13 research and innovation projects working to integrate graphene and other 2D materials in a variety of applications, the Graphene Flagship is helping to revolutionise areas from biomedicine and composite materials to electronics and energy. Read on to learn how two Graphene Flagship projects are working toward game-changing energy solutions.

Revolutionising graphene energy storage

Energy harvesting and storage are at the heart of the global transition to sustainable energy systems. By efficiently combining energy harvesting and conversion, we can unlock autonomous, self-powered technologies such as wearable electronics and personalised healthcare devices – key enablers of battery-free technology.

Carbon nanomaterials, including graphene, have revolutionised energy storage, driving advancements in batteries and supercapacitors (SCs). These innovations are vital for the sustainable adoption of renewable energy, addressing challenges like intermittency. Lithium-ion batteries (LIBs), in particular, have seen remarkable growth, optimised to deliver both high energy density and power output. However, as energy demands continue to rise, significant breakthroughs are still needed to ensure that energy harvesting and storage systems can fully meet our future needs.

At the same time, developing more efficient materials for energy storage devices has become imperative to meet the demands of emerging markets. Two-dimensional (2D) materials, such as graphene and graphene-related materials (GRMs), have earned significant attention for their potential to revolutionise energy storage. These materials are being rigorously studied in Europe and globally. However, despite substantial progress, the synthesis of graphene continues to face critical challenges. Issues such as inconsistent quality, complex production processes, high environmental impact, elevated costs, limited performance in practical applications, and scalability for high-quality production remain significant hurdles.

The Graphene Flagship’s GRAPHERGIA project aspires to put forward new ideas and technological advances to mark a significant step towards a more sustainable energy future. Central to the project is the development of eco-friendly ‘dry electrode’ fabrication methods for energy storage devices, exploiting the potential of lasers for graphene synthesis and functionalisation. By advancing laser-based, pilot-scale, and industrially relevant production processes for electrodes made from 2D materials, especially graphene and GRMs, GRAPHERGIA targets two transformative energy applications:

Self-powered smart clothing that can harvest biomechanical energy through the triboelectric effect, convert it into electrical energy, and store it using textile-embedded micro-flexible SCs.

High-performance anodes for lithium-ion battery (LIB) cells designed for space applications.

The rapid expansion of these markets underlines the need for breakthroughs in materials, processes, and system integration. The project’s innovations aim to deliver scalable, long-term solutions for energy harvesting and storage, addressing both current and future demands.

GRAPHERGIA’s vision beyond the state-of-the-art

By targeting breakthrough advancements in materials, processes, and system integration, GRAPHERGIA aims to provide sustainable, long-term solutions that meet the growing market demand for advanced energy applications.

The project employs industrially relevant laser technologies to synthesise high-quality graphene-based materials for two major application areas: triboelectric nanogenerators (TENGs) for self-charging, energy-autonomous textiles; and graphene/silicon nanohybrids as anodes for lithium-ion battery (LIB) cells.

Challenges in self-charging textiles

Current approaches to conductive textiles, which serve as the foundation of smart clothing, often rely on inks made from metallic nanoparticles or graphene platelets. However, these approaches face several challenges, including the use of non-environmentally-friendly solvents and complex fabrication processes. GRAPHERGIA addresses these challenges through two innovative approaches:

Laser-assisted graphene deposition: The project is developing a sustainable, laser-assisted process for depositing high-quality graphene electrodes directly onto textile surfaces. This patented process is a collaborative innovation by the Foundation for Research and Technology – Hellas (FORTH) and Adamant Composites.

Revolutionary power management system: GRAPHERGIA is creating a novel power management system capable of efficiently converting the discrete voltage pulses generated by body motion in TENGs into a stable DC current. This system can power wearable devices or charge micro-flexible SCs. This breakthrough, patented by the University of Gustave Eiffel, will significantly enhance the practicality of self-charging textiles.

Challenges in anodes for Li-ion batteries

Natural graphite has been classified as a critical raw material (CRM) by the European Union, primarily due to the scarcity of natural mining sites within Europe. Consequently, replacing a portion of natural graphite in anodes is becoming increasingly important to meet the growing demand. Furthermore, while graphene/silicon anodes are being explored to enhance the energy density of LIBs, a major challenge remains: reducing the domain size of the active charge-storage material, such as Si nanoparticles.

Aligned with the European Strategic Energy Technology Plan, GRAPHERGIA is advancing low-carbon technologies to tackle these challenges. The project aims to introduce a patented, laser-assisted ‘dry process’ to develop graphene-based electrodes from low-cost raw materials, including biomass; and to produce graphene/silicon anodes by decomposing carbide materials.

Exploiting the combined expertise and intellectual property of its partners, GRAPHERGIA is reshaping the future of energy-autonomous smart clothing and advanced LIB anodes. With cutting-edge graphene-based electrodes, the project is setting new standards for sustainability, performance, and scalability in energy storage and harvesting technologies.

GRAPHERGIA use cases

GRAPHERGIA will develop several demonstrators to showcase its innovative technologies:

Self-charging textiles: This demonstrator will focus on two case studies – smart clothing designed to support on-body wearables, and smart textiles for upholstery fabrics, integrating energy-harvesting and storage capabilities.

Advanced graphene/Si LIB anodes for space applications: This demonstrator involves the design, manufacturing, and testing of a graphene-based LIB module prototype tailored for space applications. It aims to validate the effectiveness of the laser-assisted fabrication technology at Technology Readiness Level (TRL) 5.

Contributing to a sustainable future

GRAPHERGIA integrates 2D materials with scalable, cost-effective fabrication techniques to deliver economically viable and environmentally sustainable solutions. Using low-cost precursors such as biomass-derived products, polymers, and other carbon sources, the project employs industrially relevant laser technologies capable of high-speed, large-area processing in roll-to-roll (R2R) lines under ambient conditions.

By significantly reducing carbon emissions, waste, and reliance on CRMs, GRAPHERGIA addresses climate change and promotes ecological sustainability. The project’s waste-free, REACH-compliant processes eliminate hazardous substances, aligning with environmental protection goals while alleviating safety and regulatory challenges.

Technologically, GRAPHERGIA’s direct laser-assisted deposition of graphene onto various substrates simplifies electrode fabrication and device integration. These inherently scalable methods have applications beyond e-textiles and LIB cells, enabling large-scale production of graphene-based films and coatings.

Ultimately, GRAPHERGIA promotes innovation aligned with EU sustainability standards and enhances industrial resilience, ensuring Europe maintains a leading role in the production and application of 2D materials.

Advancing sustainable energy solutions through next-generation supercapacitors

Supercapacitors, sometimes referred to as electrochemical capacitors or ultracapacitors, have become essential parts of the electrochemical energy storage system because of their remarkable high-power density, quick charge and discharge rates, extended cycle life (>100,000 cycles), and minimal maintenance needs. These features make supercapacitors the perfect choice for applications requiring immediate power delivery, like wearable electronics, power backup systems, and regenerative braking in electric cars. However, their very low energy density – typically less than 10 Wh/kg – is one of the main obstacles preventing their wider implementation. In contrast, the majority of commercially available supercapacitors are greatly outperformed by commonly used lithium-ion batteries, which can reach energy densities of 100–120 Wh/kg.

The goal of the Graphene Flagship’s ARMS (Atomic layer-coated gRaphene electrode-based Micro-flexible and Structural supercapacitors) project is to close this significant energy density gap while preserving the high-power density, extended lifespan, and environmental friendliness that are intrinsic to supercapacitors. The goal of ARMS is to fabricate supercapacitors with energy densities more than 50 Wh/kg by utilising cutting-edge materials science, nanotechnology, and scalable production processes. With this level of performance, supercapacitors will directly compete with batteries without sacrificing their environmental impact, cycle life, or power capabilities.

Innovative technology: Graphene and bio-based materials

The incorporation of graphene-rich bio-based carbon materials and graphene-decorated carbon fibres as electrode components is a key part of the ARMS project’s innovation. Because of its remarkable surface area, mechanical strength, and electrical conductivity, graphene is a perfect material for improving supercapacitor performance. To ensure that the materials are sustainable and high performing, the research also investigates the usage of activated carbon made from renewable biomass sources.

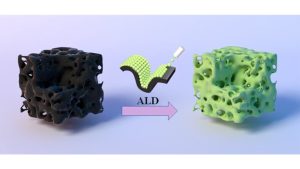

To further optimise electrode performance, ARMS employs Atomic Layer Deposition (ALD) technology to coat graphene-based electrodes with ultrathin, conformal layers of metal oxides. This process enhances the electrochemical properties of the electrodes, improving their capacitance and stability over prolonged charge-discharge cycles. The ALD technique is not only scalable and cost-effective but also allows for precise control over the coating thickness and composition, leading to enhanced energy storage capabilities.

Addressing state-of-the-art challenges

Many efforts to improve supercapacitor energy density face trade-offs like reduced power, higher costs, or shorter lifetimes. ARMS addresses these by focusing on:

Higher energy density: Graphene-enhanced electrodes and ALD coatings boost energy density to over 50 Wh/kg, narrowing the gap with batteries.

Maintained power density: ARMS preserves rapid charge-discharge capability, essential for quick energy delivery.

Eco-friendly materials: Using bio-based and graphene-based materials supports sustainability and minimises environmental impact.

Scalability and cost-effectiveness: ALD and bio-based materials enable scalable, cost-efficient manufacturing, supporting European industries.

Contribution to a sustainable future

ARMS advances sustainable energy solutions by:

Reducing environmental impact: Eco-friendly materials and biomass-derived carbon support carbon sequestration and a circular economy.

Enhancing efficiency: Higher energy density reduces recharge frequency, benefiting renewable storage and electronics.

Supporting European innovation: ARMS fosters local industry, job creation, and European leadership in energy tech.

Enabling versatile applications: Micro-flexible and structural supercapacitors enable innovations in wearables, aerospace, automotive, and portable devices.

ARMS supercapacitor applications

The ARMS project demonstrates the versatility of its advanced supercapacitors through two key applications: wireless sensors and drones.

Wireless sensor use case: ARMS supercapacitors replace traditional batteries in wireless environmental monitoring systems. By integrating a voltage conditioning circuit with the supercapacitor, the system provides reliable power under various conditions, such as cold environments (e.g., refrigerators).

Drone use case: Structural supercapacitor composites are integrated into drone components to reduce battery energy consumption. The supercapacitors provide supplementary power, enhancing drone efficiency by combining structural integrity with energy storage capabilities.

These applications highlight the potential of ARMS supercapacitors to improve efficiency, sustainability, and performance in diverse real-world scenarios.

In summary, the GRAPHERGIA and ARMS projects’ innovative technologies hold the potential to revolutionise energy storage. Through collaborative efforts within the Graphene Flagship, ARMS and GRAPHERGIA are poised to drive the next generation of sustainable energy solutions, contributing to a cleaner, greener, and more energy-efficient future.

This article was authored by Professor Spyros Yannopoulos, from FORTH, and University of Patras; Magda Spella, from FORTH; Hamed Pourkheirollah, from Tampere University; Mona Marill and Laura Argilés from AUSTRALO; and Inese Jansone, from Institute of Solid State Physics, University of Latvia.

Please note, this article will also appear in the 21st edition of our quarterly publication.

Source link