Ammonia production via the Harborbosch (HB) process was one of the most influential inventions of the 20th century. This is a challenging chemical reaction that converts hydrogen and nitrogen into ammonia. Approximately 170 million tonnes of ammonia are produced per year to meet the global agricultural needs. Ammonia production alone is estimated to account for more than 420 million tons of Co2 per year and 2% of the world’s fossil energy usage.

Practice the principles

Although simple in principle, moisture splitting is an energy-intensive process that requires a significant amount of electricity. One way to reduce electricity demand is to use high temperature steam electrolysis (HTSE). Therefore, ammonia production provides nuclear energy opportunities, especially for small modular reactors (SMRs), as it serves as a reliable source of heat and electricity.

As a result, the overall economy of carbon-free ammonia with nuclear energy can be significantly improved. The HB process, an exothermic reaction at high temperatures, can also be integrated with the HTSE system to provide the heat of evaporation of feed water and improve overall system efficiency.

Developing an integrated approach

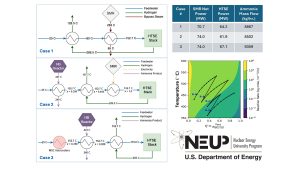

Funded by the US Department of Energy under the University of Nuclear Energy Program (NEUP), the project develops two reference designs for carbon-free ammonia plants. One design uses freshwater as a source of hydrogen, while the other design uses seawater (or brackish water). Specifically, the team focuses on developing innovative system configurations that effectively integrate SMR with cryogenic air separation (CAS) units, HTSE units, and HB units. On the other hand, in the Haber-Bosch process, it is important to identify optimal operating conditions to maximize ammonia conversion yield and ammonia production costs. Therefore, efforts have been made to optimize the design/operating conditions of major HB processes, including the reaction rate of each HB reactor and the emphasis on ammonia separation and recycle loops.

Process modeling and simulation are carried out using Aspen Plus to assess system performance for various configurations. To simplify the modeling structure of the simulation, each subsystem is modeled using hierarchical blocks. Essentially, the integrated system aims to produce ammonia with zero carbon emissions and strive for the lowest level of ammonia costs.

Current system

Current nuclear-driven ammonia systems are designed to operate with SMR based on Nuscale Power Modules (NPMs). The NPM has a thermal power rating of approximately 250 MWT and a total electrical output of 77 MWE. ⁵The current model uses a single NPM, but the system can be scaled to incorporate multiple NPMs. In current design, the HTSE stack operates at 750°C. Despite the use of significant internal heat recovery between the supply and hydrogen product flow, a large amount of latent heat of latent heat is required from external heat sources. One of the focus of the project is to evaluate various integrated configurations for preheating HTSE water supply and optimize the use of available thermal energy between subsystems.

Improved ammonia production optimization

A preliminary case study investigates three thermal integration configurations between HTSE water supply and SMR turbine steam and/or HB “waste heat” as a result of multi-stage compression and exothermic ammonia synthesis reactions (see simplified process diagram in the diagram). In Case 1, we use a hydrogen product stream and use steam to decouple the SMR and heat the HTSE feed water at 5 bar until saturated steam. The SMR bypass steam flow rate is minimized and exits the heat exchanger at 85°C. Case 2 uses an ammonia product from the HB reactor to preheat the HTSE water supply, with the remaining latent heat provided by the hydrogen product flow and the electric heater. Case 3 preheats the HTSE water supply using heat generated by a multistage compressor (MSC) before receiving additional heating from the ammonia product stream leaving the HB reactor.

As shown in the table, more power in the SMR is available for the HTSE system to generate hydrogen. As a result, Case 3 produces the highest ammonia rate by utilizing the waste heat generated by the HB unit to generate steam for HTSE. Furthermore, this figure shows the temperature profiles within each of the four HB reactors and the contour plots of reaction kinetics as a function of the temperature and dimensionless molar fraction of NH3.

The team continues to investigate innovative system configurations and carry out unit-level design optimizations, but the focus is shifted to perform system-level optimization of ammonia production costs and techno-economic analysis (TEA). Meanwhile, the project freezes the desalination and ice energy storage subsystems when using seawater or brackish water as hydrogen sources, further demonstrating the utility and potential impact of SMR-driven innovative carbon-free ammonia systems.

reference

Yüzbaşıoğlu Ae, Tatarhan AH, Gezerman AO. Decarbonization in ammonia production, new technological methods in industrial scale ammonia production and critical evaluation. Helyon 2021; 7.

https://doi.org/10.1016/j.heliyon.2021.e08257. Liu X, Elgowainy A, Wang M. Life-cycle energy use and greenhouse gas emissions for ammonia production from renewable resources and industrial by-products. Green Chem 2020; 22:5751–61.

https://doi.org/10.1039/D0GC02301A. Lee K, Liu X, Vyawahare P, Sun P, Elgowainy A, Wang M. Technoeconomic performance and life-cycle greenhouse gas emissions emit the emissions of various ammonia production paths, traditionally including carbon breeding, nuclear power, and renewable production. Green Chem 2022; 24:4830–44. https://doi.org/10.1039/D2GC00843B. Mueller M, Klinsmann M, Sauter U, Njodzefon JC, Weber A. High-Temperature Solid Oxide Electrolysis – Technology and Modeling. Chemie Ingenieur Technik 2024; 96:143–66. https://doi.org/10.1002/cite.202300137. Nuscale Power Module | Nuscale Power nd https://www.nuscalepower.com/products/nuscale-power-module (accessed September 6, 2025).

This article will also be featured in the 24th edition of Quarterly Publishing.

Source link