Puragen’s Global Award-winning technology removes and destroys PFAS Group chemicals and is based on activated carbon purification and advanced thermal reactivation.

PFAS Group Chemicals (One and Polyfluoroalkyl Materials) are a huge group of artificial chemicals that have been widely used in the industry since their introduction in the 1950s.

Thanks to specialized chemicals, you can find multiple uses in many different applications, including:

Non-stick cooking utensils Fire foam food package Fabric coating cosmetics

They are very stable molecules and are not easily decomposed in the natural environment, and as a result, they are called “eternal chemicals” by certain parts of the media. Some PFAs are defined as persistent organic pollutants (POPs). PFAS bioaccumulates in plants and animals. This is a concern as some PFAS compounds are associated with severe health risks such as immune system interference, developmental issues, and even certain types of cancer.

Concerns are rising

Although these problematic chemicals have been widely used for over 70 years, they have not been particularly interested in the current production and use, as they are keenly aware of the problems they face in terms of addressing these compounds, and their historical on-site US-related legacy issues, which have not been relatively recently, have begun to attract attention. In addition to the environmental and health and safety issues surrounding these chemicals, businesses are also facing reputational damage as public awareness grows on this important theme. Governments and environmental regulators in various regions of the world are actively studying the issues surrounding PFAS chemicals, investigating methods that may limit their use, as well as options to clean up existing contamination.

In parallel, regulators are also investigating treatment options for PFA contaminated water and air, including considering restrictions on the production and use of problematic PFA compounds, and setting appropriate and realistic limits. As examples of the former, the three most toxic PFAS compounds have been banned in the EU and the UK for many years – PFO since 2008, PFOA since 2023, PFHX since 2023. Phasing off existing inventory for compounds and affected items. In some applications, the specialized heat and chemical resistance of PFAS compounds may mean that proper drop-in substitutions may not be identified, and therefore mild rog may persist.

From a therapeutic option perspective, there are several commercially available techniques for removing these compounds to reduce PFA levels in water, as well as many other techniques in the R&D and pilot stages. Examples of commercial processes include:

Granular Activated Carbon (GAC) Membrane Filtration Ion Exchange Resin Advanced Oxidation Process

The US Environmental Protection Agency (EPA) has identified GAC as the best method for removing PFA from water, but each technology has its advantages and disadvantages.

One important advantage of using GAC over other technologies is that it occurs after PFA is removed from the water. Rather than simply focusing PFA, it requires subsequent incineration to completely destroy the subsequent medium, so a well-designed GAC filtration system, combined with advanced thermal reactivation, can recycle the filtration medium and completely destroy PFAS contaminants, resulting in a unique circular solution in the fight against these problematic compounds.

Pragen

Puragen is a leading global supplier of activated carbon filtration systems. Previously known in the UK as CPL-activated carbon and Spain’s CPL Galaquim, Puragen Group merged all its global subsidiaries in July 2025 to form a single group with a unified strategy and updated branding.

Puragen can supply activated carbon worldwide. Additionally, certain major regions may also offer a complete suite of attached services, including:

A wide range of active carbon supplied under the Filtracarb® and Filtrapure® brands. The range of mobile carbon filters manufactured in-house and rental-based manufacturing ranges for both liquid phase (Aquasorber®) and vapor phase (Vocsorber®) purification applications. Carbon recycling via thermal reactivation with discrete processes for drinking water, wastewater/environment, and high sulfur biogas applications was used. The site services team helps customers install and change out carbon and filters. Complete engineering support for supplying peripheral items such as piping, pumps, valves, etc. at sites that have not previously used activated carbon purification in the process, if necessary. Full QC and R&D backups with a variety of analytical techniques.

The Puragen team is a group of highly experienced and technically competent environmental experts who work closely with their customers to help them solve their cleansing challenges.

The Puragen team has received multiple awards for innovative technologies, including the Global Green Apple Award for PFAS Reduction Systems entitled “Search, Capture & Destroy.” The main elements of this approach can be summarized as follows:

Search: Identify specific PFA compounds in customer samples and select the best treatment solution using advanced analytical techniques such as LC-MS.

Capture: Selection of special surface-modified GACs for efficient removal of PFA from water.

Destruction: Advanced thermal reactivation that completely destroys PFA in used GACs.

Surface-modified GAC

PFAS compounds exist in a wide range of sizes and molecular composition. Standard active carbon has been proven effective in removing long chain length PFAs from water, while shorter chain length PFAs have traditionally been proven more difficult to mitigate.

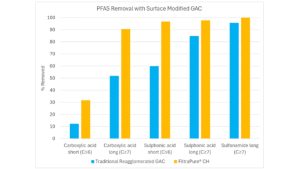

Puragen’s technical team has developed a variety of specialized GACs featuring modified surface chemistry, dramatically improving the removal performance of shorter chain PFAs. That is, it is less than 6 carbon in the chain. As shown in the graph below, removal efficiency can be increased by up to 200% compared to traditional reguromell carbon, typically used in drinking water purification applications. These surface-modified carbons, known as the Filtrapure® CH range, also improve the removal efficiency of long chain PFAs and generally last longer on customer filters before changing out is required.

Advanced thermal reactivation

The spent carbon can usually be recycled by heat reactivation in a special ki or furnace. This process removes impurities from the carbon pores and destroys them through a multi-stage process. Puragen has three separate process streams at its UK reactivation facility to recycle carbon from drinking water, environmental cleansing and biogas/biomethane operations.

Due to the very stable nature of PFAS group molecules, there has been considerable uncertainty and debate as to whether thermal reactivation as part of this process could indeed destroy PFA. Puragen has developed an advanced reactivation technology called React-Sys+. This completely removes PFA from spent carbon and destroys PFAS molecules in a three-stage therapeutic process:

Final off-gas polishing in a gas-off-gas therapeutic chemistry scrubber in a rotating high-temperature reactivating oxidant.

Independent external testing confirms that the PFA level of atmospheric emissions from the process is the same level as background measurements, and that the wastewater stream from the process does not contain detectable PFA. It has also been shown that PFA is not remaining in the reactivated GAC. This means that PFA can be used again for water treatment without reintroducing it into the environment.

Puragen can therefore justify the claim that the process not only efficiently removes PFA from water and air, but also can completely destroy PFA while recycling spent carbon.

award

Puragen received the prestigious Green Apple Award for Environmental Best Practices at an event held at Kensington Palace in London in November 2024. He was then proposed to be the UK ambassador for the Global Green Apple Award held in New Zealand in May 2025.

Therefore, if you are concerned about legacy or ongoing PFAS contamination issues with your water or airflow, contact Puragen’s team of technical experts.

This article will also be featured in the 23rd edition of Quarterly Publication.

Source link