High-performance tetrahedral materials produced in a scalable manner support the EU’s leadership in thermoelectric innovation.

The START project is driving European innovation in thermoelectric (TE) materials by pioneering the use of tellurium-free tetrahedrite (TH) materials sourced from mine waste. With strong alignment with EU sustainability goals and circular economy principles, START is entering a pivotal phase, preparing to assemble its first prototype device and taking a major step towards market readiness.

As already detailed in a previous article¹, this Horizon Europe project will leverage the consortium’s wide range of experience and innovation, from geology to mineral processing, compositional design and integration of powder-based materials, and device design and assembly, to turn its concept into reality and boost Europe’s thermoelectric industry with a sound alternative to current materials with unguaranteed supply chains.

Here you can read insights about the latest results of the project. As the project is just entering its final year of operation, further details are expected to be announced in the months leading up to the end of the project.

Main results so far

Advanced materials development

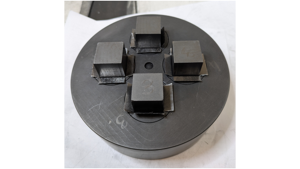

START has produced high-performance p-type TH materials through scalable methods such as high-energy ball milling (HEBM) and improved field-assisted sintering technology (U-FAST) (Figures 1 and 2). The synthetic sample achieved a record figure of merit (zT) of 1.16 at 354°C, while the mineral-derived sample at 20 wt.% enrichment (from TH-bearing minerals recovered from mine waste in a European mine) reached zT=0.97, demonstrating the feasibility of using secondary raw materials. More than 40 kg of mineral concentrate was processed, proving the waste-to-energy concept.

These results not only significantly exceed the average zT values of TH reported in the literature (typically in the range of 0.3–0.7 for materials produced at laboratory scale, depending on composition and temperature), but also demonstrate a higher efficiency of the fabrication process, with 12 samples produced in one sintering cycle. Although the synthetic sample is above the 99th percentile trend line (zT ≈ 0.308 + 0.002T), the 20/80 mineral/synthetic sample with zT = 0.97 is slightly below the 99th percentile value of 1.012 at 352°C, still showing the best performance among the TH-based TE materials.

Comparison with commercial systems

Commercially available TE materials based on Bi2Te3 or PbTe typically achieve zT values between 0.8 and 1.2 but rely on critical raw materials such as the rare and geopolitically sensitive tellurium (Te). START’s tetrahedral approach matches this performance without the use of tellurium, offering a more sustainable, EU-sourced alternative.

Device design and simulation

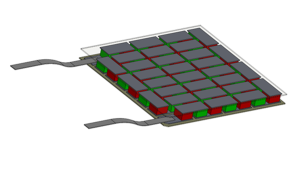

A COMSOL-based model of the TE module was developed to integrate actual temperature-dependent material data for p-type TH and selected n-type materials (Mg3(Sb, Bi)2-based materials). Using thermoelectric simulation, the pellet packing factor and height are optimized to match the incoming heat flux density in a combined heat and power application. Additionally, interfacial layers including diffusion barriers and bonding layers are incorporated into the model. Thorough thermomechanical simulations were also performed to optimize the thickness of the ceramic substrate. For reference, the size of the red and green elements of the module optimized for medium temperature applications (Figure 3) is approximately 40mm3, and the module size is 45x45mm2, consisting of unicouples of 31 p-type and n-type legs.

Environmental/economic evaluation

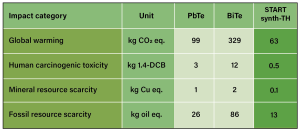

A life cycle assessment (LCA) model was performed to measure the environmental impact of START’s tetrahedral-based modules using conventional BiTe and PbTe systems. The ReCiPe.² 2016 method, which adopts a cradle-to-grave approach according to international standards ISO 14040:2006 and 14044:2006, was adopted with Ecoinvent 3.11 as SimaPro 9.4 software and database.

A life cycle inventory (LCI) is developed using the production of 1 kWh of electricity by a TE generator (TEG) module as a functional unit and includes key stages such as raw material extraction, module preparation and assembly, and TEG manufacturing. Regarding the different steps of TEG production, the literature was employed to identify and characterize the most common commercially available TEGs (tellurite-based, such as PbTe and BiTe), while data regarding TH-based TEGs were obtained both from the literature and START partners.

Preliminary results showed that the alumina plates used to construct the module had a significant impact on global warming potential (GWP), human carcinogenic toxicity (HCT), and fossil resource scarcity (FRS). This associated environmental impact is due to the high energy consumption required for raw material extraction. Furthermore, although the production of high-purity TH is a highly energy-intensive process, we observed that the n-type non-TH leg contributes significantly to the mineral resource scarcity (MRS), which is significantly higher than the p-type leg.

Comparing the GWP of tellurite-based TEG and TH TEG, the fabrication of TH module reduced CO2 emissions (CO2 eq. 63 kg) compared to those of BiTe and PbTe modules (329 kg and 99 kg CO2 eq., respectively) (Table 1). The BiTe module also has high toxicity to humans (12 kg 1.4-DCBeq.), which is significantly higher compared to the values for PbTe (3 kg 1.4-DCB) and TH-based devices (0.5 kg 1.4-DCB), and therefore the latter has a significantly lower negative impact on human health. TH modules have also been proven to have the least impact in the mineral resource scarcity (MRS) category (0.1 kg Cu eq.) when compared to BiTe and PbTe modules (2 kg and 1 kg Cu eq., respectively). Similarly, TH-based TEGs also exhibit more environmentally sustainable values in terms of FRS (13 kg oil equivalent), while BiTe and PbTe TEGs exhibit significantly higher values. Consistent with ongoing research, it was concluded that the inclusion of TH is likely to reduce the environmental impact and improve the sustainability of the delivered TEG.

next step

The goal of the final months of the project is to test the device during assembly and verify the expected performance with real measurements.

In addition to TE’s clear advantage in powering electronic devices where the use of grid power or batteries is not practical, the consortium is also very active in promoting the acceptance of thermoelectric power generation as a viable green energy production route included in the European Strategy for the Green Transition. The project has already stimulated a follow-up COST action (CA24120³) that will help foster networking and acceptance in the TE community, and plans to establish a specific organization to support the TE industry and assist in matching between European producers and potential end users.

Disclaimer

The START project is co-funded by the European Union. However, the views and opinions expressed are those of the authors alone and do not necessarily reflect the views and opinions of the European Union or the European Agency for Health Digital Administration. Neither the European Union nor the licensing authorities can be held responsible for them.

The START project is co-funded by the European Union. However, the views and opinions expressed are those of the authors alone and do not necessarily reflect the views and opinions of the European Union or the European Agency for Health Digital Administration. Neither the European Union nor the licensing authorities can be held responsible for them.

Contributor:

Bruno Vicenzi

START dissemination manager

European Powder Metallurgy Association

Filipe Neves

START project coordinator

LNEG – National Institute of Energy Geology, IP

Alvise Bianchin and Serena Busatto

START project members

MBN Nano Materialia SRL

Marcin Rozinski

START project members

Genicore Sp.Zoo

Patricia Almeida Carvalho

START project members

Shintef

Aniruddha Ray

START project members

RGS Development BV

Hao Ying

START project members

TEGnology ApS

Giovanni Borsoi

START project members

3 screwdriver

References

The Innovation Platform, Issue 18, June 2024, Pages 36-38 Huijbregts, MAJ, Steinmann, ZJN, Elshout, PMF, et al. ReCiPe2016: A harmonized life cycle impact assessment methodology at midpoint and endpoint levels. Int J Life Cycle Assess 22, 138–147 (2017) CA24120 – Sustainable Thermoelectric European Network (SUSTENET)

This article will also be published in the quarterly magazine issue 24.

Source link