The EU-funded RELIANCE project synthesises new biocidal additives, based on silica mesoporous nanoparticles and non-toxic bioactives, to generate durable and sustainable antimicrobial coatings.

Microbial colonisation of surfaces forms a dangerous reservoir for pathogens, contributing to the spread of infections, which can cause significant cost to human life and the economy at large. It is estimated that only antimicrobial-resistant infections are responsible for 110,000 deaths and €1.5bn per year in healthcare costs and productivity losses. Several antimicrobial coatings exist in the market, based mainly on the leaching of non-environmentally friendly chemicals, such as antibiotics, phenolic biocides, or quaternary ammonium compounds.

Additionally, they are formulated considering synthetic, non-biobased polymers as binders. Therefore, there is a tangible need for innovative antimicrobial coatings that are highly effective, safe, self-disinfecting, and remove bacteria, fungi, and viruses more cost-effectively than current non-biodegradable, toxic, and fossil fuel-based coatings in use.

In this context, the new Horizon Europe interdisciplinary project RELIANCE arises. Fifteen partners from ten countries bring competencies and expertise to ensure the successful design and development of the innovative, holistic solution for healthier environments.

What are the objectives of RELIANCE?

RELIANCE project aims to design and develop smart response self-disinfectant antimicrobial nanocoatings based on a new range of smart antimicrobial additives consisting of mesoporous silica nanoparticles with metallic copper in their structure (Cu-SMIN), modified with biobased bioactives: antimicrobial peptides (AMP’s) based on protein containing waste streams, and essential oils (EOs) extracted from non-edible plants. The antibacterial action of these bioactives will be tuned owing to the functionalisation of the nanoparticles with groups that respond to pH and temperature changes. In particular, two alternatives to incorporate the bioactive compounds will be considered:

The incorporation of the biobased EO into the porous substrate, to allow a controlled release of these oils to the environment under temperature or pH stimuli

The attachment of the AMP to the nanoparticle surface allows a long-term action of the bioactive compound in the environment.

RELIANCE combines contact killing and leachable antibacterial actions ascribed to the additive with the non-sticking action due to the coatings’ formulation in which the nanoparticles are incorporated, thus providing an integral, holistic solution to antimicrobial problems on different surfaces. The nature of the coatings, their characteristics (hydrophobicity and surface roughness) and their application methods (direct deposition by cold-atmospheric plasma, high throughput spraying or selective digital printing) will be specifically designed to allow not only the microbial repelling action, but also the minimum consumption of chemicals and the adhesion of the coatings to different substrates commonly found in our living environments, such as metals, plastics or textiles, and to maximise their durability (in terms of performance and antibacterial properties).

What are the main innovations of RELIANCE?

RELIANCE goes beyond the present-day possibilities of conventional chemicals by considering sustainability and eco-design criteria in the selection of the antimicrobial bioactives, and in the green synthesis of binder formulations, avoiding the use of perfluorinated compounds and reducing the consumption of organic solvents.

The antimicrobial action of the nanocoatings is adjusted to the specific application, according to the dosages and stability requirements to ensure that the nanocoatings meet the different technical and mechanical requirements in three high-added-value and demanding industrial applications:

Automotive interior parts for shared vehicles, frequently touched:

The long-lasting action required for this application limits the possibility of antimicrobial leaching, and therefore, the high number of microbes that could be found in this environment is addressed by a permanent presence of AMPs on the Cu-SMIN surfaces, to act synergistically with the Cu presence. As the concept of autonomous, shared, and connected cars is becoming increasingly popular, other physical considerations have become relevant in this context. In RELIANCE, the developed additives are applied to chromed polymeric substrates through a one-step direct deposition of Cu-SMIN by Cold Atmospheric Plasma (CAP). The experiments include either a surface activation or attaching a very thin coating (<100 nm) on the selected substrates.

Home appliances:

In our daily environments, the highest number of microorganisms is found in our kitchens. Due to food spoilage, pathogens can grow rapidly even at cold temperatures, such as in a refrigerator, and may cause disease (e.g., Listeria monocytogenes). Refrigerators are among the home appliances that raise the most concern. A study revealed that on average, the salad drawers alone in a frost-free home fridge contained 7,850 bacteria units/cm2. Considering the risk of microbes being in contact with food, an extra dosage of antimicrobial additives will be pursued for this use case application; a dosage that will be triggered by a pH change, which will activate the valves of the particles.

Protective medical textiles:

Used in hospitals and cleanroom production facilities of pharmaceutical components, biologicals, and vaccines, they can be in continuous contact with dangerous viruses, bacteria, and fungi and require a quick response and high dosage of antimicrobial additives to guarantee safe working conditions. In RELIANCE, Cu-SMIN will smartly respond to human body temperature to release the antimicrobial agent during use. Moreover, leaching will be avoided during non-working time and washing, to allow their long-term efficiency. In this case, the nanostructured bioPU organic coatings will be applied by digital printing for protective clothing for hospitals and cleanroom manufacturing facilities.

RELIANCE also provides a hazard evaluation to support the development of safe and sustainable products. It is done through an oriented Nano(eco)Toxicology testing-based strategy, guided by a thorough evaluation of the safety regulatory requirements with respect to the three applications. Efforts are made for integrating new concepts and methodologies such as ‘one substance, one assessment’ and New Approach Methodologies (NAMs).

What are the main results observed during the project lifetime?

During the initial 36 months of the project, Tekniker and Millidyne have synthesised a wide range of mesoporous silica nanoparticles of a spherical shape, average size=100-120 nm and with a high specific surface area = 700-1000 m2/g to allow the incorporation of the essential oils. Different versions of the nanoparticles, with copper, essential oils or a combination of them, have been prepared at semi-industrial scale by Millidyne.

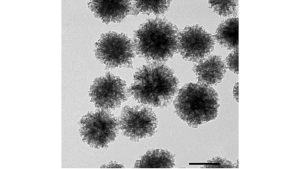

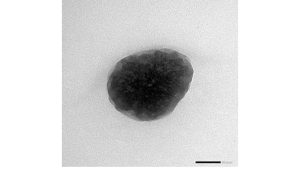

Moreover, smart-release systems were developed by grafting stimuli-responsive polymer brushes (PDMAEMA (Poly(2-(dimethyl amino)ethyl methacrylate)), PDEAME (Poly(2-(diethylamino)ethyl methacrylate)), and PNIPAM (Poly(N-isopropylacrylamide))) onto Cu-SMIN via surface-initiated atom transfer radical polymerisation. The successful functionalisation has been confirmed by different physicochemical analyses, and the incorporation of EOs has been done through a proven, scalable, and reproducible method. Smart behaviour of functionalised particles was demonstrated at lab scale via pH and/or temperature-triggered size changes, and the release of carvacrol, an antimicrobial essential oil, seems to be confirmed using electrochemical sensors developed by the University of Rome Tor Vergata. Fig. 1 shows an image obtained by transmission electron microscopy (TEM) of some of the developed Cu-SMIN particles.

Moreover, a broad range of AMP samples were produced by the School of Engineering and Architecture via alkaline hydrolysis, yielding strong antiviral activity, confirmed – up to 88.5% inhibition by the >10 kDa fraction at 50 mg/mL.

Furthermore, RELIANCE has developed greener binders to be used for coating preparation. Firstly, fluorine- and silver-free bio-based PU formulations were successfully developed by Centexbel for antimicrobial textile coatings and digital printing. These coatings exhibited excellent industrial wash fastness and hydrostatic pressure resistance. Various bio-based polyols were assessed: Sebacate-based PU demonstrated high tensile strength and durability (>20 wash cycles), Succinate-based PU showed outstanding elongation, and PCL-based PU reached 80% biodegradability. Chemical recycling of PU-coated fabrics using a ZnCl₂ catalyst enabled complete removal of the coating without degrading the PET fabric. Using a bioinspired approach with controlled physical shrinkage and a dual-layer design, a nanostructure pitch is generated, but optimisation is underway to improve repellency and durability. These results demonstrate the potential of sustainable PU systems for advanced textile applications, which is expected to be confirmed by Alsico High Tech in the following months.

Regarding the development of inorganic (hybrid) sol-gel based and fluorine free coatings for Home Appliance applications, Polyrise has prepared coatings that exhibit good adhesion, good and smooth appearance, Hardness in the range from 2 to 6 N according to ISO 4586-2 (depending on substrates) when samples are cured @160°C could be achieved, as well as WAC as high as 107° and HAC of 38° (surface energy around 22 mN/m). So far, coatings 45-65 wt% water containing formulation was applied by dip or spray, and the coatings are being nanostructured through the dispersion of RELIANCE’s nanoparticles. The coatings are being characterised by ARCELIK to analyse their suitability for being used in the interior and exterior parts of a fridge.

Finally, the cold atmospheric plasma enabled the successful deposition of antimicrobial peptides and nanoparticles onto surfaces from the automotive sector, which are being validated by Maier. Nisin and keratin peptides were deposited using nitrogen and argon plasma, and also SiO₂ and Cu-SMIN particles have been shown to be deposited by this technology, being co-injected with antimicrobial peptides. Even if the antimicrobial activity of developed coatings should be improved, the results obtained by the School of Engineering and Architecture, in collaboration with MPG, encourage further investigation in this line, as the amount of material and chemicals required by the technology is very low.

At RELIANCE, not only are the antibacterial and antiviral properties of new generation antimicrobial formulations and nanocoatings being evaluated by the University of Rome Tor Vergata in collaboration with the Defence Institute for BioMedical Research group, but also their potential hazards by INERIS and Centexbel.

The Hazard evaluation done within RELIANCE relies on a safe-by-design approach for elucidating the impact of each component of the nano-coating as well as the mixture effects. Based on the nanocoating components and on the industrial applications developed, and relying on a regulatory toxicology assessment to guide the testing strategy, we covered specific hazard categories such as skin and eye irritation (OECD 439, 492), sensitisation/allergy (OECD 442), as well as potential inhalation hazard (including in vitro using Air liquid interface exposures). Further hazard evaluation of final products, such as cytotoxicity testing directly with treated Fabrics (ISO 10993-5:2009), is also performed. Environmental hazards evaluation relies on testing on organisms such as bacteria, Daphnia, or algae.

Through all the combined approaches, RELIANCE partners aim to select nano-formulations with efficient antimicrobial properties but that are also safe for humans and the environment. At the same time, they will provide significant elements that could pave the way for a future regulatory approval and marketing authorisation of the developed products.

To validate the environmental benefits of implementing these nanocoatings, Tekniker is working on the sustainability of the process and end-of-life of the products, while the School of Engineering and Architecture is working on the techno-economic evaluation. The communication and dissemination activities of the project are guided by a comprehensive and flexible to the project’s evolution strategy developed and implemented by EUROPROJECT.

What are the expected results?

• At least two additives as novel smart-response nanoparticles, easily incorporated in nanocoatings to achieve antimicrobial surfaces.

At least two new sustainable nanocoating formulations easily applicable to various substrates to allow for a long-lasting antimicrobial effect of nanoparticles.

Three types of smart response nanocoatings with antimicrobial effect against a wide range of pathogens, sustainable enough to inhibit colonisation, without toxic active agents’ migration into the environment, easy to clean, and durable.

Novel deposition techniques and nano-structuring to achieve surfaces that repel microbe adhesion.

Recycling possibilities for the antimicrobial organic coatings so that the treated surfaces can easily be taken up in a circular economy.

Validate the new nanocoatings (performance and durability) through demonstrators

Ensure the non-toxicity, sustainability, and economic validation of the proposed nanoparticles and coatings (in vitro and in vivo tests).

Publication of scientific papers featuring new strategies for designing and developing antimicrobial nanocoatings.

Promote novel technologies for uptake by the industry.

What is the expected impact of RELIANCE in our society?

The innovative self-disinfectant antimicrobial nanocoatings generated by RELIANCE will clearly contribute to our society as follows:

Minimising the risk of spreading infections from harmful pathogens, arising from everyday human activities.

Creating healthier living and working environments and reducing sick leaves and their costs.

Reducing the exposure to harmful chemicals and improving the health of EU citizens.

Providing business opportunities to industries in the field.

Extending the EU’s reputation as a public health best practice region.

Boosting research and innovation in the EU.

Creating a more resilient society, ensuring the well-being of its citizens.

Disclaimer

This research was funded by the European Union under the European Union’s Horizon 2020 research and innovation program under grant agreement No 101058570.

Please note, this article will also appear in the 23rd edition of our quarterly publication.

Source link