The Innovation Platform spoke with Mika-Petteri Kuro, commercial director at Wisematic, to discuss the company’s core goals and contributions to Chip and Wafer Technologies.

In today’s rapidly evolving technological landscape, demand for innovative solutions continues to skyrocket. Wisematic, a pioneer of Automation Technology, is at the forefront and leverages 20 years of expertise to provide cutting-edge systems tailored to the unique needs of clients.

The innovation platform spoke with Wisematic commercial director Mika-Petteri Kuro about tailored solutions for chip and wafer innovation, highlighting the integration of flexibility, quality, and machine vision and robotics to meet the growing demand for modern technology in a variety of industries.

Can you provide a wise overview by highlighting wise objectives and key technologies?

Wisematic is a 20-year-old company founded in 2005 at Tampere University. As a system integrator, he specializes in a variety of types of automation, including robotics, machine vision sensors, manufacturing component assembly, quality control, and more.

From a technical perspective, our projects often include the integration of machine vision and robotics to suit the specific requirements of each application. An important aspect of our work is focusing on small components that can present challenges that many other companies are hesitant to deal with. At Wisematic, we accept these professional needs and customize our solutions to effectively meet your requirements.

Flexibility is a key strength within the wise range. Our robot cells are designed to be a basis for the future. This means not only evaluating the current requirements of your product, but also predicting future needs. The goal is to avoid creating overly stiff solutions and allow adaptability to future changes.

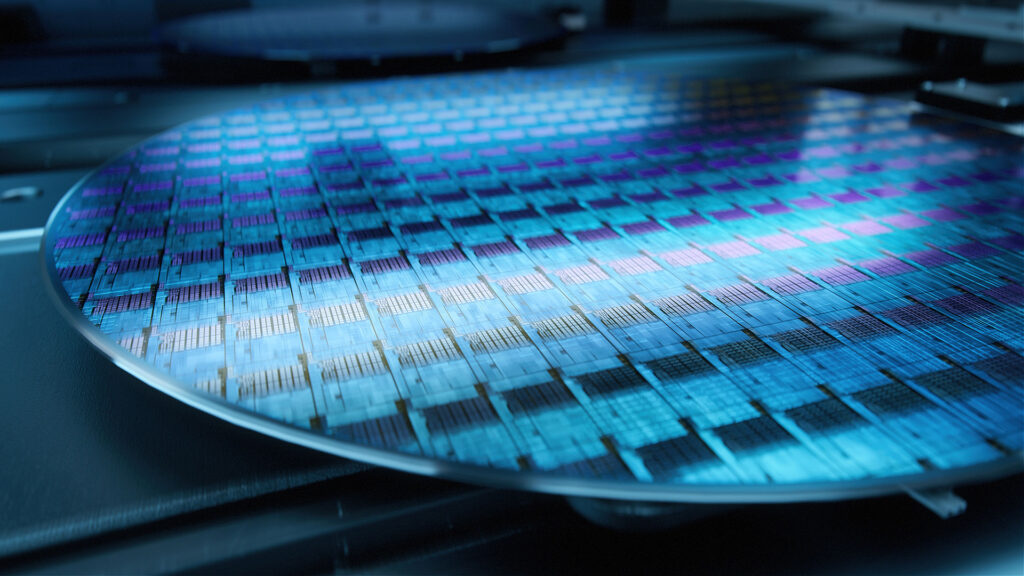

The company takes great pride in its commitment to quality. Open 24/7, our customers have a production process solution with over 99% availability! This is the incredible performance of complex automated cells, including robotics, conveyors, machine vision, and high speed operations. When ordering robot cells from us for assembly or manufacturing, we consistently recommend integrating quality control measures. We frequently utilize machine vision technology to employ shortwave infrared rays beyond visible light. This feature allows you to see through the silicon layer, position the chips accurately, perform quality control checks, and make sure everything is positioned and oriented correctly.

Chip and wafer technology is becoming increasingly essential to society. Can you explain in detail why they are integral to modern technology and how they affect the various industries today?

Chips are constant and demand is growing. Every device I use today, at home, at home or elsewhere, is equipped with a chip. Comparing the latest computers and mobile phones with past computers, it is clear that the chip performance has been significantly improved. Thanks to advances in chip manufacturing technology, modern chips are much smaller and allow calculations to be performed faster.

With the rapid advances in artificial intelligence (AI) and quantum technology, looking to the future, it is clear that further development of chip technology is essential. One promising direction is the use of light for data transmission, which could lead to the development of photonic integrating circuits or chips.

Lasers are increasingly used in a variety of applications, especially within the automotive sector, and play an important role in the sensors used by self-driving cars. Furthermore, in countries like Finland, laser integration in space technology is becoming more pronounced.

These advancements will undoubtedly affect a variety of industries. However, the rise in technology presents a challenge. As the number of devices increases, so does energy consumption. This consumption will continue to increase unless we develop chips that can deliver equal or better performance while consuming less energy. Here, light integration has proven once again beneficial, and from a manufacturing perspective, new technologies need to be developed to promote these innovations.

What are the latest innovations in chip and wafer technology introduced by Wisematic? How do these developments stand out from industry competitors?

Recently, we have been working with Tampere University to develop a system that assembles and executes quality control for Photonic Integrated Circuits (PICS). The sector is still relatively new and few companies are exploring it. This makes the university’s partnership particularly valuable.

Additionally, we have developed a chip flipping machine for assembling two-layer laser chips. Here you need to flip the top layer over. These machines can be customized to meet the needs of specific customers and can create unique solutions that are not easily available from the shelves.

The wafer has vertical storage. It is especially suitable for use on the next stage of production or wafers waiting for an already-determined wafer that is waiting for shipment. This automatic storage is designed for items such as wafer carriers. We also developed an equipment front-end module with wafer alignment and positioning. These can be placed as feeders in front of the process machine.

In your opinion, what are the most important challenges facing the chip and wafer industry today? And how do you prepare wisely to navigate these?

There are two main considerations. First, how can you effectively utilize photography alongside traditional silicon and other semiconductor technologies?

Once these applications have been identified, the next step is manufacturing, and there will play an important role. Our focus is on developing devices that integrate these chips, including optical components.

The third challenge is the energy in both the manufacturing of the chip and the chip itself. How can you design and build energy-efficient chips for your rapidly growing needs?

What trends in wafer and chip demand are wise observations and what is the company’s long-term vision for adapting to the evolving technology landscape?

In addition to the growing focus on photonics, there is a push to establish competitive chip manufacturing capabilities within the US and Europe. Currently, the majority of chip manufacturing takes place in China, Taiwan and Southeast Asia. The EU and the US are pursuing their own chip initiatives to develop manufacturing capabilities within the region. However, the goal is to focus on creating specialized chips as well as producing standard chips.

Another important point is that tools for assembling these components are not always readily available, and this is also a wise factor. In many cases, partially missing but necessary tools include operations with photographs, lasers, double layer chips and other related items. Our goal is to help businesses maintain automated manufacturing at an increased pace needed by the market.

This article will also be featured in the 23rd edition of Quarterly Publication.

Source link