Professor Stefanie Dehnen, executive director of the Karlsruhe Institute of Technology (Kit), explains how the BICMAT project unlocks new frontiers of material chemistry through the exploration of Bismuth Cluster compounds.

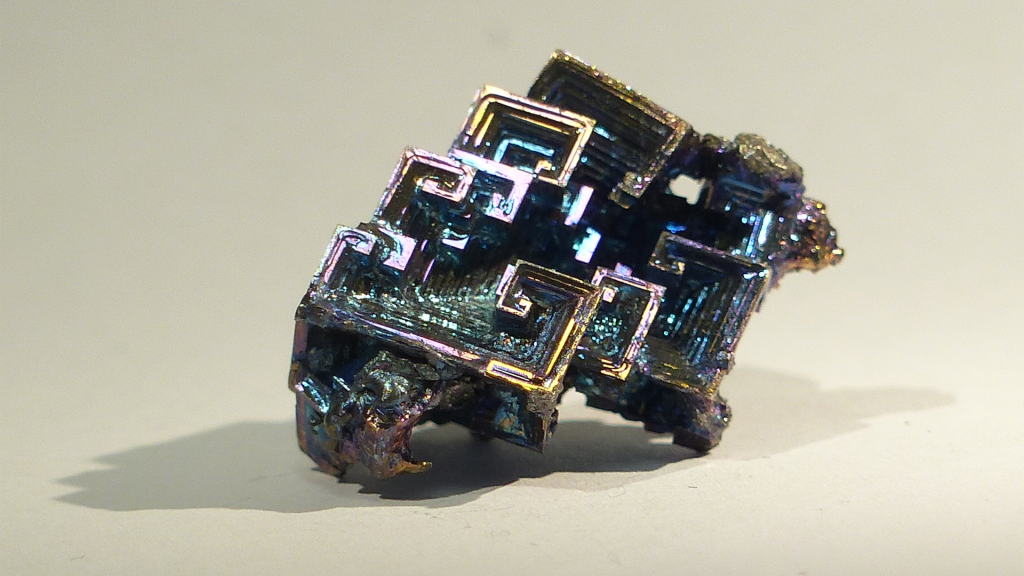

Bismuth is a unique element that has been previously overlooked in research compared to other metals and half price in the periodic table. However, its unusual properties and chemical versatility offer untapped possibilities for the development of next-generation materials.

The BICMAT project, led by Professor Stefanie Dehnen of the Karlsruhe Institute of Technology (Kit), is working to expand bismuth knowledge and create whole new materials using bismuth-based clusters. Supported by ERC Advanced Grant, the BICMAT project aims to discover, isolate and understand new vismuscular slusters, providing a window into untapped molecular architectures and materials based on them.

The Innovation Platform spoke to Professor Danen and learned how her team uses basic chemistry to open new doors in materials science.

Can you outline the BICMAT project and key goals?

The BICMAT project focuses on screw-mask cruster-based materials. Starting with the synthesis of molecular clusters (“zero dimensions”, 0D), they are used to not only promote knowledge of these nano-based architectures, but also lead them to higher dimension materials. I would like to know what these materials can do for us. For example, if configured in a particular way, can these compounds be able to host or separate the gas, and ultimately act as catalysts for small molecule activation? Or can you store lithium or sodium ions before acting as a battery material?

It also uses quantum chemistry and machine learning insights to make synthesis easier and make the results as useful as possible. To discover everything you need to know about these compounds, we utilize experimental methods such as spectroscopy and diffraction along with theoretical tools before taking the next step towards material properties.

Why is bismuth different and what is it possible for new materials?

Bismuth is a very special element. Although it has a fairly high conductivity, it is considered a metalloid because it is within the semiconductor range. Its structure is similar to that of arsenic and antimony, and is associated with the structure of black phosphorus. The structure shows typical metal orientations with a dense packaging of atoms with more isotropic interactions. Bismuth is a very heavy element. This is the heaviest (semi) stable element. It also shows a special nature in chemical reactions.

What makes bismuth particularly special is its total non-toxicity. This is especially interesting when looking for new materials. All of its adjacent elements are highly toxic, but for some reason there are non-toxic islands, which is why bismuth is currently frequently investigated in all kinds of chemicals, physics and even medical applications. It is used in metalorganic chemistry and purely inorganic chemistry, such as perovskite-like materials for solar power generation. Now, our idea is to use that knowledge to include clusters in these materials and develop completely new nanostructured cluster-based materials.

As mentioned previously, the possibility of using clusters as catalysts such as battery materials and gas storage or separation offers a much more harmful alternative to many of the materials used today. We want to achieve very functional new properties, but there is no toxicity in some of the materials currently in use.

Regarding bismuth treatment, there are challenges as our previous knowledge in molecular and material chemistry is limited. Overcoming these challenges is a trial and error process that involves many experimental reactions. However, if you overcome them, you can realize the fields of new properties. The application of prediction theory tools can further help streamline the process.

Your team is developing a whole new way to connect these clusters to 1D, 2D, and 3D materials. Can you share the amazing assets and breakthroughs that have emerged from this approach?

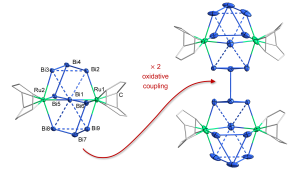

When working from 0D to other dimensions, one surprise included clusters reported based on their interesting structural and binding features. Then, a few years later, another student achieved the same cluster, but those pairs were connected by bonds. Such cases highlight the large knowledge gaps surrounding the formation processes that occur within the reaction solution and the need to learn more about them. One important part of the project is to monitor and model responses so that they can design and control this instead of being a surprise.

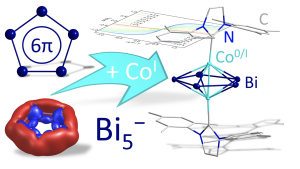

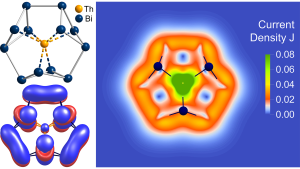

Another lesson I learned was the clusters formed from three rings. Considering the squares of four bismuth atoms, three of them are connected by bismuth bismuth bonds to form a ring. This very specific cluster has caused a lot of questions and now I understand more about it. It is the so-called all metal aromatic system, the largest metal π aromatic system with the strongest ring current per electron, which also emphasizes the specificity of bismuth. By chance, this helped us dive into the field of metal aromaticity that we may use in the future. Another example of such a species was recently realized in a systematic study of capturing a five-membered aromatic ring made solely from bismuth atoms. This was successful by using cobalt atoms to trap the ring. This helped to report the first complex of this type of metal complex based on this unusual metal aromatic cycle.

Many of our structures start to surprise us, then we investigate them and learn more about their formation. We can help us to look at the very early stages of the reaction and design the next step.

Could you please explain in detail the progress of the machine learning side of the project?

At this stage, machine learning is still early in development, mid-project. We have planned to develop more so far, but it is a very time-consuming and computationally expensive process. Currently, we are still providing data and knowledge from the site to this process, but we are beginning to see the initial results evolve. Once the data feeding process is put together, the output increases rapidly. Within about 6-12 months, we hope to reach the point where we can learn from the data and achieve predictions of how to perform the reaction more efficiently by using the most appropriate reactants for a particular target structure.

Where is the strongest real-world impact for these bismuth-based compounds?

One of the strongest influences lies in the field of catalysts. We found that even small units of bismuth, such as the hydrogenation of olefins, can be useful in such activities. These compounds can design their activation properties very well, as they differ in how they form.

They also want to gain more insight into their use as materials for example solar power and batteries. Another potential application is to use them to form specifically structured printed semiconductor devices.

If the researchers and industry partners reading this article want to contribute or build your discoveries, what collaborations and expertise would you be happy to welcome as your project continues to grow?

We welcome directions on how to create a device from these materials. Now we are working with colleagues working on printing them. However, this is not currently on the project as it is a relatively new development. We hope that we can manufacture work equipment from them, whether it is the nanoparticles made from them or the materials themselves.

Device manufacturing is not our specialty. For example, inkjet printing requires compounds in stable printable inks. This requires a lot of expertise other than cluster chemistry. The ink is a high-tech mixture and requires the appropriate combination of solvents, stabilizers, etc. Therefore, instructions regarding the appropriate ingredients are required from experts in this field. And we can say how these will probably interact with the cluster and adapt this if necessary. So this can only be done in collaboration.

Industry partners are also needed. Nowadays we can only work on very small scales and need industry input to help scale up. In some cases, our responses are so specific that we need direction from the industry, so we can understand what they need and how they can meet their requirements.

This article will also be featured in the 23rd edition of Quarterly Publication.

Source link