Advanced water treatment and repair techniques remove PFA with more than 90% efficiency, helping the industry meet regulatory standards.

Industry around the world faces increased pressure to manage PFA discharges, repair contaminated sites, and safely deal with dangerous liquids such as firefighters (AFFF). To address this challenge, Photon Water, founded in 2018 and the recently launched Brand Photon Remediation (2024), offers a comprehensive suite of solutions that combine advanced water treatment, waste management, and soil and groundwater remediation.

“By leveraging years of research, patented nanotechnology and international field experiences, we provide a complete toolbox for PFAS management. From industrial wastewater treatment to on-site repair.”

TECPFAS™: Industrial wastewater treatment

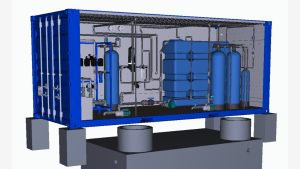

Photon Water’s TECPFAS™ system is designed to allow water reuse while removing high efficiency of PFA from water. Modular multi-stage systems can be adapted to a variety of industrial operations. It offers both flexibility and rapid deployment.

A specific example is a collaboration with Jihostroj, a Czech manufacturer of aviation parts. The pilot project tested TECPFAS™ with two types of water. Wastewater from the electroplating process and rainwater collected from the facility site. After installing the full-scale system, the PFOS concentration in the treated wastewater decreased to below 10 ng/L, exceeding 8,000 ng/L, achieving removal of over 99.5%. Approximately 70% of the treated water was recycled into production, providing significant operational savings, making the investment financially viable within a few years.

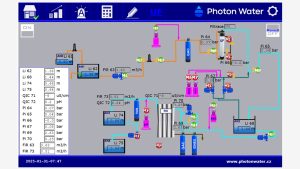

The system is operated via an industrial computer with graphical interfaces integrated into remote monitoring and photomatic applications, allowing real-time tracking and control of the treatment process.

“Our priority is to help industries improve operational efficiency while tightening regulations,” says Petr Kvapil. “TECPFAS™ not only effectively removes PFA, but also allows a significant portion of the treated water to be recycled into production. This is an example of how environmental responsibility and industrial efficiency can go hand in hand.”

WaterGuard Nano™: in-situ groundwater repair

Legacy contamination from historic PFA use remains an immediate global issue. Waterguard nanotechnology provides an efficient and disruptive approach to PFA repair in groundwater. This patented solution combines zero-valent iron nanoparticles (NZVIs) with low-strength electric fields to enhance the degradation of PFA and co-dynamics more effectively than nanoiron treatment alone. WaterGuard Nano is available only through photon repair and represents one of the most advanced in-situ repair techniques on the market.

Field applications and real-world projects demonstrate that Water Guard nano can remove 70% to 90% of PFA and related contaminants. This process occurs entirely underground, minimizing site destruction and ensuring continuous operation can be continued without interruption.

This technology is highly adaptable and can be customized to site-specific conditions, such as electrode placement, injection well configuration, and liquid suspension formulation. It can also be integrated into treatment trains along with other repair approaches, such as Photon Remediation’s patent-pending soil repair techniques, Bioremediation and EarthGuard Prb™. This flexibility allows for an overall repair strategy that can address multiple contaminants at once.

For example, in an ongoing project using chemical manufacturer Solvay, WaterGuard Nano is combined with bioremediation to target hydrocarbon contamination, demonstrating the versatility and effectiveness of the technology across different contaminants.

This system uses non-toxic materials, environmentally safe processes, can drive solar energy, and requires less energy than many original standard alternatives.

PFAS Eliminator: Safe liquid and foam disposal

The European Union is leaving the challenge of abolishing PFA-based firefighting forms, safely abolishing existing stocks, and replacing them with many facilities while cleaning up contaminated infrastructure. Addressing this need, PFAS Eliminator offers mobile and fixed solutions for the safe disposal of PFAS contaminated liquids and foams (AFFF).

The system can process up to 15m³ per day, and PFA concentrations of up to 150,000 ng/L, reducing it to below 10 ng/L. Combining multiple technologies, it achieves maximum efficiency, including mechanical filtration, ultrafiltration, reverse osmosis, activated carbon, and ion exchange.

Solution

To ensure safe operation, the PFAS eliminator is equipped with a fire prevention system, comprehensive occupational safety and health documentation, and detailed operating procedures.

From research to real world impact

Photon Water’s solutions are supported by rigorous research and collaboration with scientific and policy networks. The company participates in European and national R&D programs, including Advanced Remediation Technologies’ PFAS_TECH, EICLAR on next-generation bioremediation, LifePopwat on the wetland systems on Zoos’ sustainable water management, or Life4Zoo.

This commitment to rigorous science and real-world development has allowed us to build a track record of international projects across the Czech Republic, the EU, Australia, China and more, with photon water and photon repair.

Clean water, clean energy

As part of the Photon Energy Group, companies benefit from the synergy of clean water and renewable energy. Water treatment and repair systems are equipped with solar energy and can operate independently of the grid. This reduces costs and increases the sustainability of cleanup projects.

Today and tomorrow’s solutions

The key benefits of integrated photon water and photon repair solutions include:

High efficiency: Up to 99.5% PFAS removal. Environmental safety: Non-toxic materials, low impact in-situ repair, and integration of renewable energy. Operational Flexibility: Modular, mobile and containerized systems for water reuse: Up to 70% of treated water have been recycled to production. Regulatory Compliance: Designed to meet European and international standards. Comprehensive Services: From risk assessment to monitoring and maintenance. Global Experience: Projects in the Czech Republic, EU and Australia.

Through practical solutions and innovative technologies, photon water and photon repair allow industries to take meaningful actions today, creating a safer and cleaner environment.

This article will also be featured in the 23rd edition of Quarterly Publication.

Source link