Can the Horizon Bioreactor solve the scaling crisis in precision fermentation?

The success of precision fermentation (PF) – a technology platform reliant on the controlled cultivation of microbial or eukaryotic host systems for high-value product generation – hinges entirely on the ability to successfully transition from small-scale laboratory processes to industrial production volumes, often exceeding 10,000L. This scale-up is the singular most significant technological bottleneck currently facing the biotechnology sector. The difficulties encountered are rooted in complex, scale-dependent physical phenomena that govern process efficiency, including the management of chaotic fluid dynamics, the mitigation of mechanical shear stress on sensitive cell membranes, and the imperative of ensuring the uniform distribution of gas, heat, and nutrients across the immense volume. When these engineering challenges are not addressed optimally, the result is poor homogeneity, restricted cell viability, and, ultimately, commercial failure.

Fundamental failure modes of vertical stirred tank reactors

For more than half a century, the vertical stirred tank reactor (STR) has been the undisputed industry standard. However, the vertical design exposes critical limitations when pushed to the high-density, high-viscosity requirements of modern PF processes.

Homogeneity failure and hydrostatic pressure

The height-to-diameter ratio of traditional tall STRs creates inherent disadvantages. As vessel height increases, the hydrostatic pressure gradient from the top surface to the bottom outlet becomes substantial. This gradient results in significant and unavoidable inequalities in the distribution of dissolved oxygen (DO), nutrients, and pH, creating zones of starvation or metabolic stress. This lack of true homogeneity severely limits the maximum achievable cell density and overall reactor productivity.

The viscosity and mass transfer barrier

Achieving the high volumetric oxygen mass transfer coefficient (kLa) necessary for intense aerobic fermentation relies on high impeller speeds, typically in the range of 400 to 800 revolutions per minute (rpm). This kinetic strategy demands excessive energy input to generate turbulence and maximise the gas-liquid surface area. This strategy fails dramatically when the fermentation broth develops non-Newtonian, shear-thinning characteristics – a common trait of high-density microbial or filamentous fungal cultures, or cultures that excrete extracellular polysaccharides. In this high-viscosity state, the flow transitions into the laminar regime. This transition prevents the efficient transfer of momentum from the impeller to the bulk fluid, leading to severe localised mixing problems. Despite high energy expenditure, the fluid forms ‘caverns’ or stagnant zones immediately surrounding the impeller, isolating vast volumes of the broth from effective oxygenation and nutrient distribution.

The shear contradiction in cell viability

The reliance on high-speed impellers creates zones of intense turbulent energy dissipation (EDR) at the impeller tips, which define the maximum local shear stress within the reactor. For fragile organisms, such as specialised filamentous fungi or sensitive mammalian cells used in cellular agriculture, this localised, maximal shear determines the extent of cell lysis and viability loss. The core geometric limitation of the vertical STR is that it intrinsically links the necessary performance (high agitation for oxygen transfer) with destructive mechanical energy input (high shear). The system is therefore constrained by a physical zero-sum game between maximising oxygen efficiency and preserving cellular integrity.

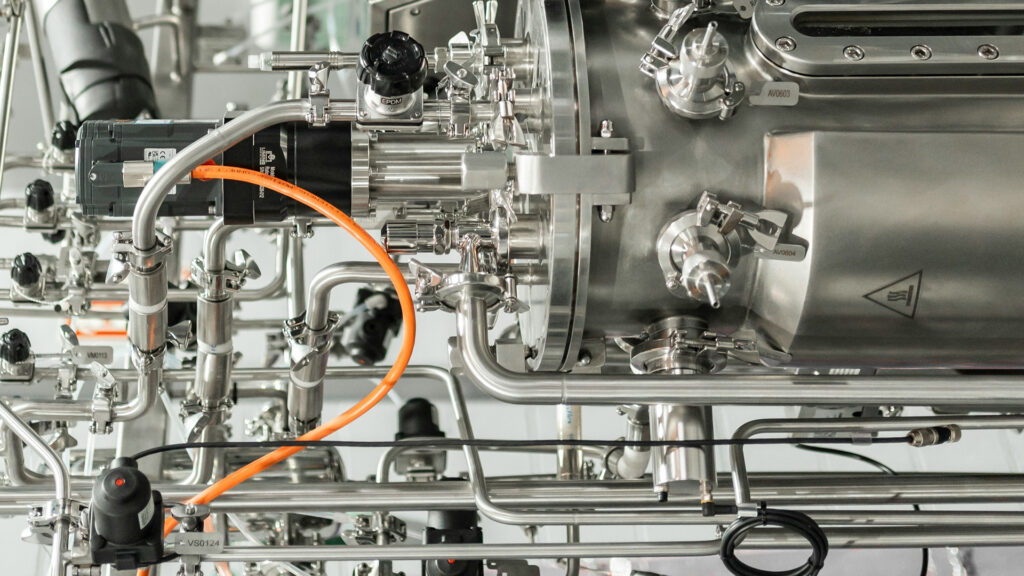

The Horizon Bioreactor: A decoupling strategy

The horizontal geometry of the Horizon Bioreactor (HBR) represents a sophisticated engineering response, designed to circumvent the hydrostatic and rheological constraints that dictate the failure of vertical systems at scale. By reducing the height-to-diameter ratio, the HBR achieves superior mixing of viscous fluids with reduced specific power input and effectively minimises the hydrostatic pressure impact, thereby eliminating the severe DO and concentration gradients that plague tall vessels. Furthermore, this form factor offers compelling structural and economic advantages, removing the need for complex, load-bearing foundations, fixed access platforms, and expensive overhead cranes, which simplifies facility construction and reduces long-term maintenance complexity.

Core technical design and ultra-low shear operation

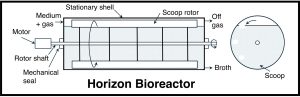

The Horizon Bioreactor is a novel platform that fundamentally achieves the decoupling of high mass transfer efficiency from damaging mechanical shear forces. It is composed of a stationary horizontal cylindrical vessel containing an internal axial rotor equipped with unique scoops designed for aeration and agitation.

Ultra-efficient mass transfer at ultra-low speeds

The rotor’s scoop mechanism facilitates highly efficient surface renewal, contacting the liquid broth with the headspace gas to initiate a controlled liquid-gas vortex. This method achieves a high volumetric oxygen mass transfer coefficient (kLa) of >100/h. The engineering breakthrough is that this performance is achieved while the rotor operates at an ultra-low speed of only 1 to 10 RPM. This minimal operational speed dramatically minimises mechanical shear forces, making the system inherently compatible with highly sensitive cell lines, and simultaneously cuts the energy costs associated with agitation by a profound margin compared to vertical STRs (400–800 rpm).

System robustness via dual strategy

The HBR utilises a robust dual strategy for ensuring optimal gas delivery. It combines its low-RPM kinetic surface renewal with thermodynamic enhancement. The bioreactor is designed for hyperbaric operation, capable of pressurisation up to >10 BAR. This hyperbaric control substantially increases gas solubility within the medium, providing a reliable buffer against gas transfer limitations. This combination ensures that, even when viscosity rises and conventional mechanical gas dispersion fails, the system maintains high gas delivery, thereby bypassing the viscosity-driven failure mode of traditional STRs.

Shear decoupling and uniform energy

The HBR achieves a highly uniform distribution of mechanical energy across the entire volume of the liquid medium. This is the definition of the platform’s hydrodynamic advantage: it effectively decouples low mean power consumption, necessary for bulk mixing, from potentially damaging maximum local shear. This characteristic is paramount for reliable industrial-scale cultivation, particularly in emerging high-volume sectors like cellular agriculture, where cell viability is directly threatened by traditional high-shear environments.

Hydrodynamic control and plug flow kinetics

The HBR provides a mechanism for advanced hydrodynamic control by effectively utilising plug flow behaviour. Unlike conventional reactors that are designed to approximate a continuous stirred tank reactor (CSTR), which assumes instantaneous and uniform mixing, plug flow allows fluid elements to move sequentially through the reactor path. This feature enables the maintenance of beneficial concentration gradients along the reactor length. For bioprocesses where accumulating products are inhibitory to cell growth, these defined gradients offer a critical process advantage by preventing the entire culture from being exposed simultaneously to peak inhibitory concentrations. Furthermore, plug flow can support sequential nutrient feeding profiles or localised processing steps along the horizontal axis.

Economic disruption through integrated continuous bioprocessing (ICB)

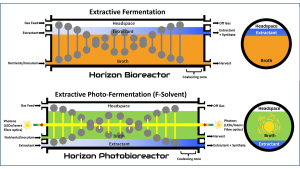

The most potent disruptive feature of the Horizon platform is its inherent design for integrated continuous bioprocessing (ICB), specifically the seamless integration of primary product recovery.

Extractive fermentation: Eliminating product inhibition

The HBR integrates precision fermentation with continuous product recovery, often termed ‘broth milking’ or ‘extractive fermentation’, within a single unit. The system achieves real-time product removal using a novel gas/liquid/solid contacting system. This mechanism accomplishes continuous separation without relying on external, high-maintenance technologies like membranes, filters, or high-speed mechanical separators, avoiding associated capital costs and fouling risks. The continuous removal of inhibitory metabolites – such as organic acids or alcohol – eliminates a critical metabolic bottleneck. This capability enables significantly intensified fermentation, supports extended operational cycles far beyond typical batch limits, and results in a major increase in overall product yield. This integration represents a profound process shift where the physical act of separation directly enhances the biological productivity.

Financial and strategic advantages

The efficiency, low energy demand, and structural compression inherent in the HBR design translate into powerful economic leverage.

CapEx and OpEx reduction

By consolidating fermentation and primary DSP into a single unit, the HBR minimises the need for extensive, sequential DSP equipment, large hold tanks, and complex purification trains. This drastically reduces the necessary facility footprint and complexity. The platform is claimed to reduce capital expenditure (CapEx) by two to five times compared to traditional vertical bioreactor facilities. Operational expenditure (OpEx) can be reduced by up to 75%, driven by the profound energy savings from the ultra-low RPM agitation, combined with reduced labour for material transport and quality control (QA/QC) associated with batch operations, and lower working capital tied up in inventory.

Scalability and market parity

The HBR’s ability to maintain sustained efficiency from laboratory scale (20L) up to very large industrial volumes (over 100,000L) provides a predictable path for scale-up. This acceleration of efficiency gains reduces the production cost curve, positioning sustainable bio-based products to achieve cost parity with traditionally sourced, low-cost commodities.

Expanding market suitability: Plant cell culture for commodity production

The HBR’s technical advantages – managing high viscosity and maintaining extremely low local shear (1–10 RPM operation) – are particularly valuable for sensitive plant cell suspension cultures (CSC). Plant cells are significantly larger (20–50 μm in diameter) than most microbial cells and are highly sensitive to hydrodynamic shear, which can restrict the mechanical agitation techniques available for adequate oxygenation. Furthermore, high-density CSC, such as those used to produce plant-based commodities like coffee or high-value phytochemicals, often become highly viscous due to the excretion of extracellular polysaccharides (EPS). This high viscosity leads to severe mixing and diffusion problems that traditional vertical reactors struggle to overcome. The HBR’s gentle, uniform energy dissipation and superior viscosity handling make it a viable, scalable, and robust platform for the industrial production of these shear-sensitive, high-viscosity cultures, offering a resilient alternative production method to conventional agriculture.

Expanding versatility: Integrated photobioreactor (PBR) and co-cultivation

The Horizon Bioreactor is designed for maximum versatility, able to operate as a high-efficiency photobioreactor (PBR) by incorporating specialised LED lighting within the internal rotor mechanism. This design provides optimised light distribution and energy delivery essential for cultivating photosynthetic organisms, including microalgae, cyanobacteria, and anaerobic phototrophs. This PBR functionality broadens the HBR’s market applicability to areas such as biomass production and wastewater treatment.

Taking advantage of its dual capabilities – ultra-low shear agitation and integrated PBR functionality – the HBR is uniquely suited for the co-cultivation of cultivated meat cells and microalgae. This strategy is a breakthrough in resource efficiency, establishing a mutually beneficial, closed-loop metabolic system within the reactor. Cultivated meat cells are highly sensitive to external shear, making the HBR’s gentle mixing regime ideal. In this system, microalgae act as sustainable metabolic partners: they consume the carbon dioxide (CO2) and nitrogenous waste generated by the high-density animal cells and, in return, use the rotor-integrated light to produce the crucial oxygen (O2) required for aerobic growth. This photosynthetic oxygen supply minimises the need for costly and potentially damaging external gas sparging systems and optimises the growth environment, significantly enhancing the viability and cost-efficiency of cellular agriculture processes. Microalgae can be engineered to produce mammalian serum proteins and, when secreted into the broth, could provide the vital growth factors for the animal cells, thus replacing expensive foetal bovine serum.

Conclusion and future outlook

The diversification of bioreactor geometry is driven by the structural and rheological necessity of overcoming critical engineering constraints – viscosity limitations, mass transfer inefficiency, and damaging shear stress – that vertical systems fail to address efficiently at scale.

The Horizon Bioreactor provides a comprehensive technological solution achieved through a dual strategy: technical decoupling (separating high kLa performance from destructive mechanical input) and process decoupling (integrating fermentation and primary separation). This dual decoupling strategy provides the foundation for its immense scalability and economic potential. Its superior suitability for highly viscous, inhibitory, and shear-sensitive processes, combined with its PBR and co-cultivation capabilities, fundamentally challenges the limitations of conventional batch biomanufacturing. The industry validation of the horizontal form factor signifies its acceptance as a necessary step in process intensification for the future of sustainable industrial biotechnology.

The fundamental shift in bioprocessing represented by the Horizon Bioreactor necessitates collaborative development to fully unlock its potential across diverse bio-based markets. We invite industrial partners, academic research groups, and technology developers specialising in areas from high-value biopharma and advanced materials to sustainable chemical synthesis and wastewater valorisation, to explore joint development programmes. By leveraging the HBR’s integrated capabilities – including its ultra-low shear environment, PBR functionality, and continuous extractive processing – industry partners can accelerate R&D cycles, validate novel organisms and products, and refine process parameters. This collaboration is essential to broaden the HBR’s application envelope and establish a new benchmark for resource-efficient, high-productivity biomanufacturing worldwide. Get in touch!

Please note, this article will also appear in the 24th edition of our quarterly publication.

Source link