This research explores how surrogate materials and testing can advance our understanding and predictability of UO₂ fuel under extreme conditions.

As the global community strives to decarbonise its energy systems, nuclear power remains a reliable cornerstone – its future increasingly dependent on our ability to understand and enhance fuel performance under extreme conditions. These include the end-of-life stage of nuclear fuels and transient events such as loss-of-coolant accidents (LOCA) – a scenario exemplified by the Three Mile Island accident.

At the forefront of this effort is Dr Tianyi Chen and his research group at Oregon State University, whose latest work investigates the burnup effects in uranium dioxide (UO₂) fuel using surrogate materials and advanced mechanistic modelling. By uncovering the underlying mechanisms of fuel performance and degradation in such scenarios, the team aims to improve the utilisation of fissile materials – thereby reducing the cost of nuclear energy – and to support the design of reactor systems with enhanced resilience to potential accidents.

Reframing fuel development: From empirical guesswork to predictive science

For decades, the development of nuclear fuel technologies has been constrained by a reliance on empirical, trial-and-error methodologies. In the traditional approach, developers conduct integral irradiation tests that mimic service conditions – essentially hoping to ‘guess right’ about fuel performance. Data from successful designs are retained for qualification, while insights from unsuccessful tests are often discarded. This once-through, intuition-driven process has proven to be both time-consuming and cost-inefficient, significantly delaying the deployment of advanced fuel forms.

In response, the nuclear research community is embracing a predictive, science-based approach to fuel design and qualification. As articulated in Phyllis King’s Advanced Fuels Campaign Execution Plan (INL/EXT-10-18954, Rev. 9), this new paradigm centres on the use of mechanistic fuel behaviour models, supported by analytical experiments, to guide development. Rather than relying solely on large-scale integral tests for discovery, researchers now prioritise resolving key phenomena through targeted, small-scale studies that feed into validated, reusable models.

At the core of this modern framework is separate effects testing, which plays a foundational role in developing and validating mechanistic models. Because the degradation of fuel performance often arises from multiscale and multiphysics phenomena, separate effects experiments are designed to deconvolve this complexity, reducing behaviour to its underlying dependencies on material properties and microstructural features. As a result, the models developed through this strategy can predict fuel behaviour with higher fidelity and across a broader range of operational and accident conditions than current empirical models.

One emerging strategy within separate effects testing is the use of surrogate materials. These materials offer several key advantages, particularly for studying high-burnup fuel behaviour:

Lower radiological hazards and handling costs compared to highly irradiated fuels, which require specialised facilities such as hot cells.

Greater flexibility in experimental design, enabling systematic studies across a wider range of variables.

Tailored representation of specific fuel features, such as grain sizes and porosities, allowing researchers to isolate the role of individual microstructural characteristics in performance degradation.

Dr Tianyi Chen’s current research, funded by the DOE Nuclear Energy University Programme (NEUP), exemplifies this science-based approach to understand and predict fuel performance. In collaboration with Rensselaer Polytechnic Institute (RPI), the University of Florida, Idaho National Laboratory (INL), and Los Alamos National Laboratory (LANL), the project integrates surrogate materials, ion irradiation, and out-of-pile lab-scale mechanical testing to investigate degradation mechanisms associated with radiation damage and fission gas evolution – a key factor that limits fuel lifetime and affects safety margins during transients and accident conditions. The research specifically focuses on enhancing the predictability of fission gas behaviour as it relates to evolving microstructure and defect dynamics, as well as understanding the mechanical degradation induced by irradiation. These efforts are central to the development and validation of mechanistic fuel performance models, forming a robust scientific basis for a more efficient and cost-effective fuel qualification strategy.

In the following section, we present specific examples where surrogate materials are employed to isolate and investigate critical mechanisms of fuel behaviour under irradiation – demonstrating how this targeted, model-driven approach is advancing modern nuclear fuel research.

(For more information, the readers are referred to Nuclear instruments and methods in physics research B 515 (2022) 48-60, Journal of Nuclear Materials 577 (2023) 154297, and “Understanding burnup effects in UO2 using surrogate materials”, presented by Tianyi Chen at TMS 2025, Las Vegas, Nevada, 23-27 March, 2025. Work was supported by a Laboratory Directed Research and Development project, 19A39-061, led by Dr Fabiola Cappia, under the U.S. Department of Energy, Office of Nuclear Energy, Idaho Operations Office Contract DE-AC07-051D14517, and the NEUP programme led by Dr Tianyi Chen under the award number of DE-NE0009489.)

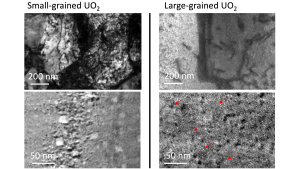

The effect of grain size on irradiation damage development and fission gas behaviour

Adding small amounts of certain materials – called dopants – to uranium dioxide (UO₂) fuel can help it form larger grains during manufacturing. These larger grains make it harder for fission gases, like xenon, to escape quickly because the gas has to travel farther to reach the grain boundaries where it can be potentially released. This helps the fuel hold onto the gas better, which can improve its performance and extend its life in a nuclear reactor. However, scientists weren’t sure how this larger grain structure would hold up under the intense conditions inside a reactor. Irradiation damage to the fuel’s structure can not only let gas escape more easily but also weaken the fuel, making it more likely to crack.

To study this, researchers made UO₂ samples with different grain sizes using a technique called spark plasma sintering (SPS), performed at Rensselaer Polytechnic Institute (RPI). These samples were then exposed to high-energy xenon ions – similar to the gas released during nuclear fission – to see how they responded to radiation damage. The results showed that UO₂ with larger grains held up better, with less structural damage and slower gas bubbles growing. This research provides experimental support that larger-grained UO₂ fuel may not only trap fission gases more effectively but also be more resistant to radiation damage – making it a promising option for improving nuclear fuel safety and longevity.

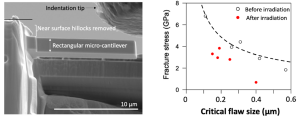

The fracture property degradation due to irradiation damage

To build reliable, physics-based models that simulate cracking and microcracking in nuclear fuel – a process that occurs at high burnup and can degrade thermal properties, release fission gases, and lead to more severe damage during accidents – it’s essential to know how the fracture toughness of UO₂ changes with irradiation. Directly measuring this property in reactor-irradiated fuel is extremely costly and complex, but surrogate testing using ion-irradiated samples offers a more cost-effective alternative for understanding these effects.

In the figure below, we show how micromechanical testing was used to bend a tiny bar of UO₂ – just 2 micrometres thick, which is about 1/50th the diameter of a human hair – to measure its fracture behaviour both before and after irradiation. The results reveal that irradiation reduces the fracture toughness of the material, making it more prone to cracking. These advanced, small-scale techniques are crucial for providing the detailed material property data needed to support mechanistic modelling of fuel performance, especially under extreme conditions.

Looking ahead: From surrogates to realistic simulations of fuel behaviour

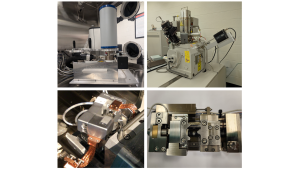

Building on these findings, Dr Tianyi Chen will continue to expand his research using the specialised tools and facilities developed at the School of Nuclear Science and Engineering at Oregon State University. His future work will explore how nuclear fuel becomes weaker or more prone to cracking under a wide range of conditions, such as high temperatures, varying pore structures, radiation-induced changes, and different fuel compositions.

To better understand how gases trapped in nuclear fuel – such as xenon – are released under a variety of conditions, the project team is developing several innovative testing methods. One approach, led by Professor Jie Lian at Rensselaer Polytechnic Institute (RPI), uses spark plasma sintering (SPS) to apply controlled thermal shocks that simulate the rapid temperature changes that can occur during reactor accidents. Another method, developed at Oregon State University, utilises a customised thermogravimetric analysis / differential scanning calorimetry and mass spectrometry (TGA/DSC-MS) system equipped with both blast and steady-state heating modes, allowing researchers to precisely study fission gas release under both accident-like transients and normal operating conditions.

The insights gained from these experiments will directly inform physics-based computer models developed by Professor Michael Tonks’ group at the University of Florida, and will contribute to the ongoing refinement of large-scale simulation tools like BISON – a key fuel performance code continuously improved at Idaho National Laboratory, including by team member Dr Pierre-Clément Simon. By combining innovative experimental techniques with advanced modelling, the team is helping to bridge the gap between controlled laboratory research and the complex realities of fuel behaviour inside a working nuclear reactor – ultimately supporting the development of stronger, longer-lasting, and more cost-effective fuels for the future of clean energy.

About Dr Tianyi Chen

Dr Tianyi Chen is an Assistant Professor of Nuclear Science and Engineering at Oregon State University. His research encompasses radiation effects, radiation damage, and property degradation of nuclear materials, with a particular focus on accelerated testing and advanced characterisations. Dr Chen utilises a combination of experimental and computational tools to tackle engineering and scientific challenges in nuclear materials.

Before joining Oregon State University, Dr Chen was a Postdoctoral Research Associate at Oak Ridge National Laboratory from 2016 to 2018. He earned his Ph.D. in Nuclear Science and Engineering from Texas A&M University (2010-2015), during which he also worked at Idaho National Laboratory and Argonne National Laboratory. Dr Chen received his Bachelor’s degree in Physics from Peking University in 2010.

Dr Chen has received recognition for his work, including the Outstanding Scholarly Output Award from Oak Ridge National Laboratory and the Young Former Student award from the Department of Nuclear Engineering at Texas A&M University.

Please note, this article will also appear in the 22nd edition of our quarterly publication.

Source link