Selpaxt’s innovative surfactant-ligand-assisted membrane filtration (SAMF) technology is transforming the PFAS processing environment, and is designed for complex water supply.

We present a single problem as it is widely considered to be one of the most sustained contaminants ever created. These “eternal chemicals” ubiquitous in industrial applications, consumer products and environmental matrices resist degradation of nature, and involve bioaccumulation of living organisms, pose serious risks to public health.

Despite the growing demand for a complete ban on PFA, manufacturers claim it is irreplaceable in many applications. As a result, stricter laws have been introduced to mitigate the environmental and health effects of PFA.

The message is clear from the EU’s water resilience strategy, drinking water directives, reach proposals, and country-level PFAS action plans that are costly civil settlements and more stringent restrictions on recent well-known criminal convictions.

The need for effective and scalable PFAS treatments is always present, but the success in eliminating PFA from complex water flows remains a horrifying challenge.

But Chromafora’s Selpaxt technology is changing that.

Selective Chemistry for the Removal of PFA: How It Works

At the heart of Chromafora’s innovation is patent-pending solutions. Selpaxt – A chemically enhanced ultra-highering process that selectively separates and enriches PFAs containing elusive ultrashort chain variants.

Known as innovative surfactant ligand-assisted membrane filtration (SAMF), SELPAXT combines unique surfactant chemistry with optimized membranes to provide unparalleled PFAS concentration rates.

SELPAXT works similarly to traditional ultrafiltration systems, but features unique, water-soluble, and biodegradable chemicals administered continuously according to an incoming water matrix. The PFAS molecule is then selectively retained, concentrated in the membrane barrier and is excreted intermittently at a rate of up to 0.1% of the total water volume.

Using ISO certified container-based modular format or customized installation, SelPaxt systems are fast deployable and tailored to site specifications. Similarly, necessary pretreatments such as filtration and oil separation can be incorporated based on the quality of water that is incoming.

With low energy consumption and reduced environmental footprint, SelPaxt does not only offer consistently low OPEX. This allows businesses to optimize PFA removal while improving sustainability. Unlike traditional separation and concentration techniques such as activated carbon, ion exchange, and foam fractionation, Selpaxt is independent of adsorption and foam. Instead, it uses its own selective chemistry to bind PFA molecules and remove them via a pressurized membrane step, providing high selectivity without sacrificing flow or stability.

Due to its high selectivity, SelPaxt specifically captures PFAS molecules without picking up additional or alternative contaminants such as organic matter or salts. This makes it particularly suitable for complex water streams that are generally high in contaminants.

This approach offers four technical advantages:

The removal efficiency of up to 99.7% effective for ultra-short, short and long chain PFAS molecules can withstand high tolerance of total water volume to complex water matrices with elevated TOC levels up to low waste residues of 0.1%.

Up to 99.7% removal effect

With stricter regulations set to take effect, PFAS producers and water treatment companies will need to raise their ante when it comes to total PFA removal. SELPAXT’s innovative SAMF technology has been proven to remove up to 99.7% of all PFAS molecules from complex water streams.

Importantly, SelPaxt consistently offers effectiveness rates of up to 99.7%, maintaining performance over a long period of time. Unlike other forms of PFAS treatment, such as GAC and ion exchange, SELPAXT does not require frequent media exchange or constant manual monitoring. Instead, high contaminant resistance means that it is not affected by complex water stream contaminants and can maintain consistently high removal rates without costly media exchange or high OPEX (see Figure 3).

Effective for ultra-short, short, and long-chain PFAS molecules

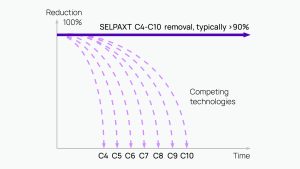

Existing PFAS therapies, including granular activated carbon (GAC), ion exchange, and reverse osmosis (RO), offer a variety of efficacy in the removal of long-chain PFAS molecules, but are limited in efficacy when it comes to eliminating ultra-short or short-chain PFAs.

To date, much of the research on the harmful effects of PFA has focused on long chain molecules, so limited amounts of regulation have also been concentrated on long chain PFA.

However, with a new era of regulation in sight, recognizing the detrimental effects of ultra-short and short-chain PFAs means that viable and cost-effective elimination methods are essential.

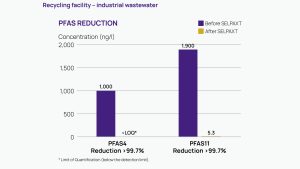

Fortunately, SelPaxt has proven to be extremely effective at removing all kinds of PFA from complex water streams, including ultra-short and short chains. As shown in Figure 1, SELPAXT successfully reduces the PFAS4 level of industrial wastewater from 1,000 ng/L to below the detectable limit at the customer site, exemplifying the high effectiveness rate that SELPAXT has in short-chain PFA.

Various case studies, lab testing, and analyses have made Selpaxt’s ability to remove ultrashort, short, and long chain PFAs well documented and demonstrated in real-world environments.

The residual amount of PFAS waste is less than 0.1%

Like other existing PFA removal techniques, SELPAXT works by separating and enriching PFA to promote subsequent destruction or sequestration. Unlike existing solutions, the SELPAXT system is able to concentrate PFA waste to a residual volume of just 0.1%. In contrast, reverse osmosis (RO) usually produces 15-25% residual waste.

For example, for every 1,000 liters of treated water, SelPaxt produces just 1 liter of PFAS waste compared to 150-250 liters of RO.

As a result, customers using SelPaxt systems do not need to promote secondary destruction frequently. Second, this can significantly reduce the costs associated with PFA destruction and management.

High resistance to complex water matrices with increased TOC levels

Most existing PFAS technologies capture and concentrate long chain PFAs, but the process of doing so also captures other contaminants in the water stream. As a result, all media used will be saturated and must be replaced frequently manually.

Conversely, the high selectivity of SELPAXT means that only PFAS molecules are captured and the continuous addition of proprietary chemicals at the correct dose to achieve optimal PFA reduction. With automatic “clean-in-place” (CIP) between batches, no media exchange is required. This significantly reduces the costs associated with PFA and requires minimal on-site maintenance.

Targeting of short-chain molecules: a new era of PFA removal

When water is contaminated with PFA, it always contains a variety of ultra-short, short-chain, and long-chain molecules.

If the technology is able to remove long chain molecules, it limits the amount of total PFA that can be successfully eliminated. As regulations become closer, removing ultra-short and short-chain molecules is a necessary method to ensure that total PFA concentrations fall below mandated thresholds.

However, this is not the reason why companies should be actively and actively working to remove ultra-short and short-chain PFAS molecules from the water stream.

Increased scrutiny of short chains

To date, PFAS regulations have focused almost exclusively on long chain PFAs through relatively large studies of these types of molecules. To avoid this regulation, familiar PFAS manufacturers shortened the length of the carbon chain and converted essentially regulated long-chain PFAS molecules into unregulated short-chain PFAS molecules.

However, raising awareness of the potential health and environmental impacts of short-chain PFA, coupled with the desire to explain manufacturers and industries, means that greater scrutiny has been applied to both ultra-short and short-chain PFAs.

As a result, we may see an increase in regional, national and international regulations targeting ultrashort and short-chain PFAs and long-chain molecules. Effective short-chain removal techniques have become essential for businesses that rely on “flying under the regulatory radar” of short-chain PFAs.

The principle is “polluters pay”

In addition to focusing on long chain molecules, many of the existing PFAS regulations are related to drinking water, not wastewater or groundwater. This will effectively leave taxpayers funding the cost of removing PFAs to utility companies, often publicly owned.

This is in stark contrast to the EU’s widespread approach to “polluter-paying” environmental policies. This can be expected to extend this principle to the PFAS treatment mission.

Already, some of the costs associated with compliance with the EU’s revised Drinking Water Directive are expected to be borne by the contaminants. It is still unclear whether a framework comparable to the “Extended Producer Responsibility” (EPR) scheme and UWWTD have been implemented in conjunction with PFA, but it is certainly expected that there will be a higher demand for effective industrial wastewater PFAS treatment technologies as pressure is placed on PFAS contaminants.

Preparing for the future without PFAS

A complete and clear PFA ban may be unlikely, but with increasing regulations it is essential to eliminate PFA from wastewater, groundwater and drinking water. Reputation management, industrial manufacturers, utilities and water treatment companies not only strengthen and optimize PFA removal to achieve regulatory compliance, meet stakeholder expectations, and limit both civil and criminal liability.

Fortunately, Selpaxt by Chromafora offers a reliable and cost-effective treatment that removes up to 99.7% of ultra-short, short and long chain PFAs. Selpaxt is used alone as part of a water treatment train or in combination with technology as part of a water treatment train. Already, we are enabling businesses to embrace a safe, sustainable, PFAS-free future.

This article will also be featured in the 23rd edition of Quarterly Publication.

Source link