Researchers have changed standard adhesives to 3D to print bone-like materials directly on fractures, paving the way for use in the operating room.

The devices that have been tested in rabbits so far are particularly useful in correcting irregularly shaped fractures during surgery, researchers say.

“As far as I know, there is virtually no practical example of applying technology directly as a bone substitute,” Jung Seung Lee, a biomedical engineer at Sungkyunkwan University in South Korea, told Live Science in an email. “This makes this approach very unique and sets it apart from traditional methods.”

Large bone fractures or other defects usually require bone grafting and the use of metal fasteners such as pins and plates to support the fracture as the broken bone heals. However, the shape of these implants is not unique to fractures in a particular patient, and therefore inadequate bone alignment can lead to poor stability.

Previous studies have shown that 3D printed custom bone grafts can be performed for individual patients, but these require considerable time and effort, preventing them from being used during surgery during flight.

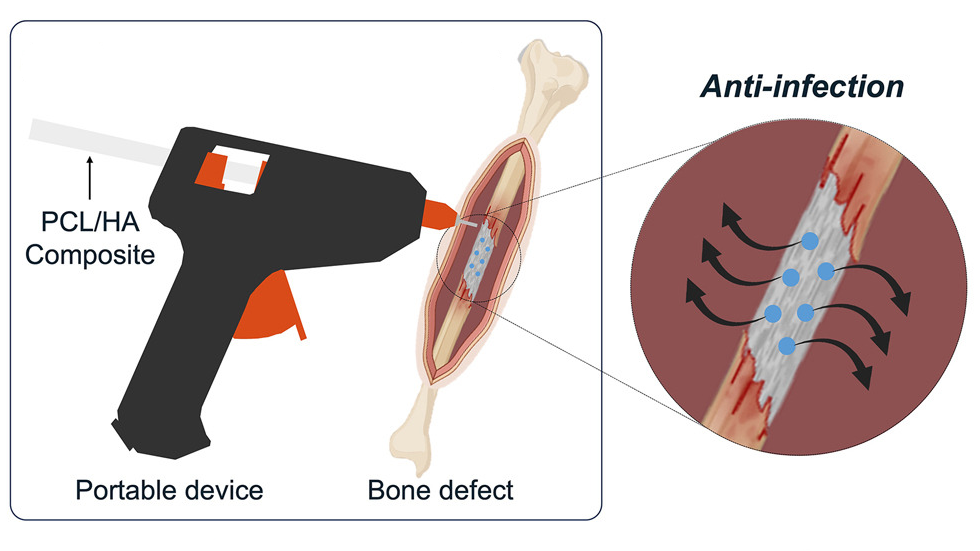

In a survey currently published on Journal Devices on Friday (September 5), Lee and her colleagues detailed a new method of using glue guns to print bone replacements directly on fractures. In this study, they successfully tested the technique of rabbits with leg fractures.

Related: Injectable Goo can fix joints without surgery, according to early studies

You might like it

Basic 3D printing generally uses flexible plastic threads. This is heated and formed into the desired shape. However, Lee and colleagues created a filament consisting of two materials: polycaprolactone (PCL) is hydroxyapatite (HA), a mineral form of calcium that has been used in previous studies to create biodegradable bone scaffolds and is important for bone structure. Additionally, two antibiotics were incorporated into the filaments to prevent infection. These drugs slowly diffuse out of the filaments over several weeks.

Using a modified adhesive gun to push calcium-based filaments out at low temperatures, the researchers created a small shape that cools to body temperature within 40 seconds. Afterwards, during lab rabbit surgery, 3D bone grafts could be printed directly on fractures and defects.

“This highlights a major advantage in reducing surgical time and improving procedural efficiency under actual surgical conditions,” Lee said in a statement.

Researchers tested 3D printed bone grafts on a New Zealand white rabbit (Oryctolagus cuniculus). They covered the fractures with metal plates and screws, filled the rabbit’s bone defects with special bone-like filaments or traditional bone cement, followed the rabbit’s progression for 12 weeks.

Rabbits with new fracture treatments have had better results, including three months of bone tissue formation and dense bone growth compared to rabbits that consider traditional treatments. By the end of the study period, they noted that the experimental bone material had deteriorated by about 10%.

“We used the rabbit model to confirm the therapeutic potential of this technology,” Lee told Live Science, saying further research into larger animal models is needed before the technology can be used on humans. Nevertheless, Lee said, “We believe this approach could be used more widely in future trauma surgeries.”

Source link